5 1/2 saw blade due wood is an important tool for cutting This unique blade assist individuals to slice excellent and precise straight cuts. There is a right saw blade for every job and the 5.1/2" Saw Blade performs well in many different types of cuts that you will be doing with your circular or miter saw! Some of the most useful things to know about this saw blade are:

The 5 sometimes 2 saw blade, one good thing about it is that you are able to make precise cuts. That is to say, the cuts are clean and perfect, an essential element for a number of projects. If you are making furniture, or a book shelf for example – fitting all the pieces so tightly together as possible is just good craftsmanship. 5 1/2Inch Saw Blade: The small teeth are sharp and close together. This design assists the blade when cutting wood easily and no longer sideways or misaligned giving a clean cut every time you use it.

The 5 1/2 inch saw blade is also able to handle many different tasks. A versatile blade, it works well for both thin and thick block of wood. This blade is perfect whether you are working on a small craft project or even something as challenging as making your own furniture. It also divide many varieties of wood like softwood or hardwood. Since the 5 1/2 saw blade is so versatile you do not need to have change blades for various cuts or types of wood. It helps getting job done faster and you can now move onto completing your project with out switching to different tools.

The 5-1 / 2-inch blade is also plenty stout. This indicates that it can handle extensive use without any tearing or damage. This is a strong and durable bag made from good material. It is very important as it will be possible that the blade can last for a long time and maintaining good functioning, just like when new. The 5 1/2 saw blade has a longer number of cuts before it becomes dull or wears down, which allows you to finish cutting more wood. It provides a longer life and you will be able to work with this particular blade for long even after many projects without needing replacing your blade too often;

When you are cutting wood, ordinarily most of us would want to get through what we are doing as fast as humanly possible. This is perfect because the 5 1/2 saw blade makes it easier to cut quickly while still maintaining the utmost quality. Thanks to its sharp teeth and an intelligent design, it is able to cut through wood at a fast pace with precision. This saves time, and when it comes to projects spending more could ruin a good cut. If you can work quickly and efficiently, the overall quality of woodworking project will be much better.

The importance of quality is Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We implement 5 1 2 saw blade quality control measures throughout production In order to increase durability and effectiveness we employ high-quality alloy steels suited to specific application of tools We also use advanced techniques for heat treatment using vacuum and deep cooling processes Our dedication to excellence is evident in our product's abrasion resistance toughness and extended service life putting us at the forefront of our industry

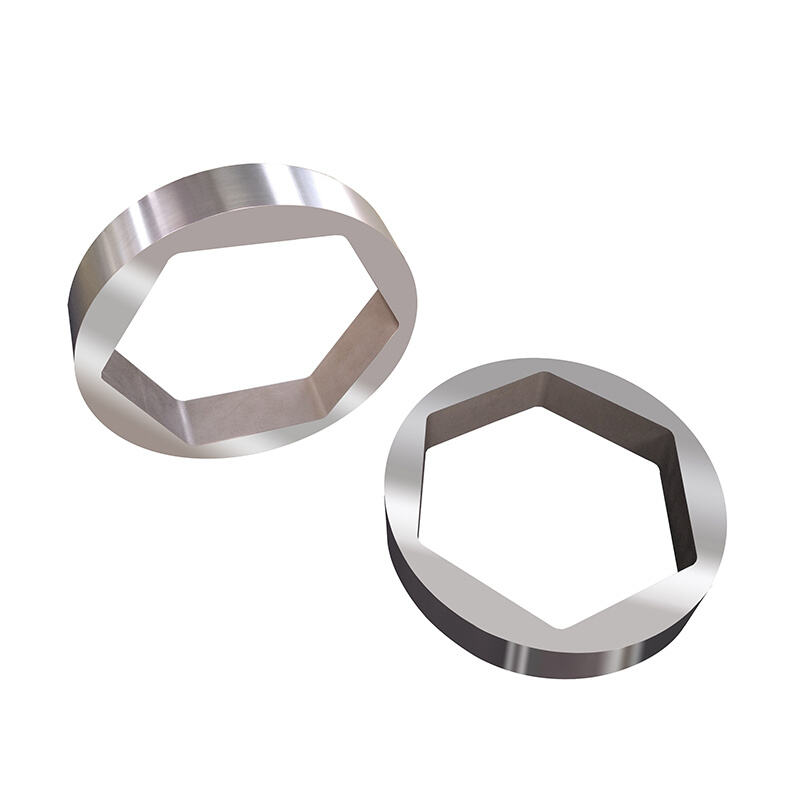

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in 5 1 2 saw blade, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

Our manufacturing facility covers more than an area of 8 000 square metres and is equipped with cutting-edge machines This allows us to efficiently 5 1 2 saw blade orders that require high precision and quality We follow strict quality control procedures making sure that our raw materials are of the highest grade and that every blade is subjected to CNC processing to ensure precision

Each blade is thoroughly inspected using electronic calipers after production to ensure that it conforms to 5 1 2 saw blade We conduct hardness tests after heat treatment to ensure compliance with stringent quality standards This ensures that our products satisfy or exceed expectations of customers