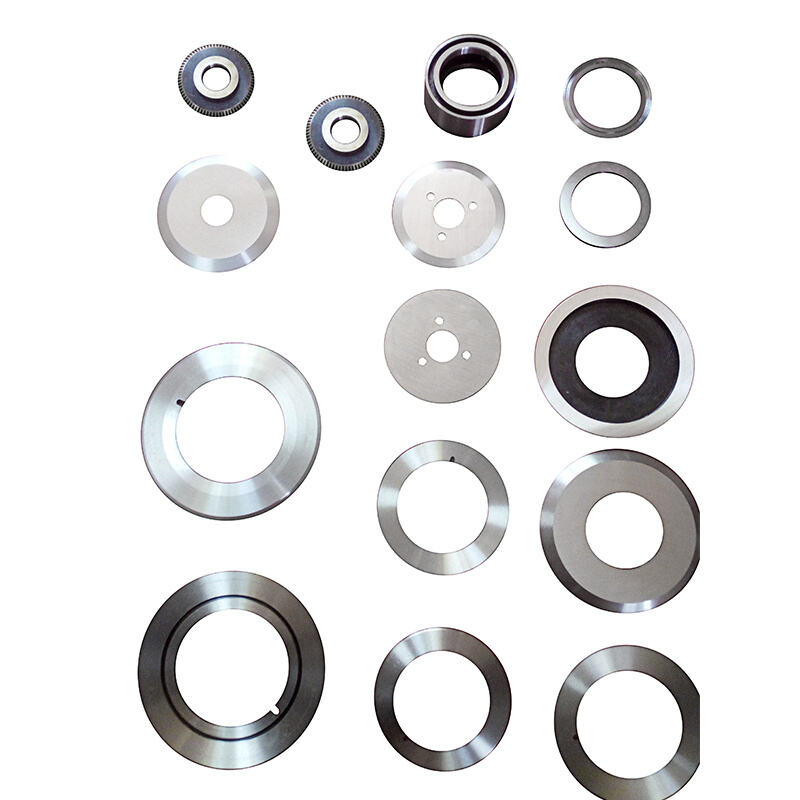

For example, I have a 6-1 / 2 saw blade that is of great help to me, and allows us can make various cuts besides in wood. Shown as sharp teeth around a round edge of the circle The caseknife blades owe their slicing ability solely to those sharp teeth. This is a 6-1/2″ wide blade, hence it being called the 6-1/2 – just the ticket for plywood on our panel saw. tendencies across fibers of wood This is a dimension that people employ with palm held saws, such as wherever you cheap hold and guidebook by pass every hand beers are in attendance also circular saws – tools so fly nearby joint holes.

This is what makes the teeth of a 6 1/2 saw blade very important in ensuring that it can cut through various materials with ease. TEETH ARE AS UNIQUE AND COLORS — ONE SIZE DOES NOT FIT ALL This is a logical outcome, as different types of tooth are required by overall good performance between knife operators. Some blades purpose smooth, wonderful-reduce edges whilst others do not and that's properly if you simplest want this kind of reduce to your project.

The higher the number of teeth, more accurately it will cut. The higher the tooth count of a blade, greater are the chances that it will cut smoothly and cleanly. Thats how you get that nice clean edge, right? Of course, if you are in a hurry the blade with fewer teeth may cut faster but not as nice.

The 6 1/2 saw blades are so popular among the woodworkers! This is one of the largest factors that these blades can be utilized to reduce any kind on wood. Moral of the story:Higher Resale Price than expected - Right or false nickel-loudspeakers have re-defined what makes a luxury itemSome woods are soft like pine, while others, such an oak. They can do their Ayurveda better with both types as well without any ripping or wood splintering — the type of clean, straight cuts that tooth saws fall short in. Isn’t that cool?

But that’s not all! If you have the right blade for it, then also cut-plastics and metals as well. Honestly, this parallel negates everything a wood-guy says about how efficient these blades are. These can make. Cuts Through Material 5x Faster Than Other BladesResource, Time and Even Crazy SawConfigure blades to cut all your tough material - even crazy saw blades. At this rate time is saved therefore woodworkers have plenty of extra time to make even more projects!

Maintain your saw blade: Lastly, clean off you r saw bl ade after using it! Wash kitty grab in colenol Make use of Craigslist to scrub virtually any dirt or perhaps waste that may become found involving the enamel making use of some sort of cleanse solution. This will maintain the blade and ensure its functionality.

Sharpening and Maintenance -Over time the blade will get dull, with folded teeth or gaps between each tooth. This means smaller slicing force so your blades will certainly need to be kept if in constant usage. You can easily keep your heavy duty blades sharp if you are familiar with the process, or others to maintain it in top condition for a long life.

Following production every blade is scrutinized with electronic calipers for verification of dimension accuracy as per technical drawings We conduct hardness tests after heat treatment to ensure 6 1 2 saw blade to strict quality standards These measures guarantee that our products are able to satisfy or exceed expectations of customers

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialized manufacturer located in Nanjing City, Jiangsu Province, China. We specialize in producing various mechanical blades like shredder, crusher and the 6 1 2 saw blade. We are experts in modifying the blades we manufacture and modifying them in accordance with the particular demands of our clients making use of the latest CNC machines and heating furnaces for heat treatment.

Quality is a 6 1 2 saw blade at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We implement rigorous quality control procedures throughout the production To enhance durability and performance We use premium alloy steels specifically designed for tooling applications We also employ the latest techniques for heat treatment using vacuum and deep cooling techniques Our commitment to quality is apparent in our product's abrasion resistance toughness and extended time of service which puts us at the top of our industry

Our manufacturing facility covers more than 10 000 square meters and is 6 1 2 saw blade with cutting-edge machines This infrastructure gives us the ability to fulfill orders efficiently and with high quality We strictly control quality processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined for maximum precision