If you plan to work with plywood, a must have tool is the circular saw blade. Plywood is a type of special wood that consists of many thin sheets, called veneers glued together. This wood is used in a lot of cool and fancy projects such as shelves, cabinets, tables etc. You can do some really nice, clean cuts with a circular saw when you use the correct blade for cutting plywood. That being said here are the top 5 best circular saw blades to cut plywood.

Diablo D1050X Circular Saw Blade 10″; It comes with (50 to body). It is the best for plywood and can make very clean, accurate cuts. This is why it works well for things like woodwork and other DIY projects. The blade also comes with some special non-stick coating which maintains the coolness of that blade and helps out so you cut through things better fence sitting thereangoing to talk.

Irwin Marathon 14020 Circular Saw Blade: It is a cutting blade that measures around seven and one-quarter inches in diameter, which means it can underperform as you are trying to cut through significant plywood. The blade has 24 teeth to cut through wood neatly and cleanly, from thin sheets up to thicker layers. These are best suited for diverse kinds of cuts including jig sawing, ripping, and cross-cutting.

DeWalt DW3106P5D60I Circular Saw Blade:- DeWalt is a renowned brand name, the length of this circular saw blade is 10 Inch has tooth set of 60. It is the perfect saw for cutting plywood. Built of durable materials, this blade is strong and sturdy providing safety even with the toughest of plywood. It also has a patented design that helps to minimize vibration and improve cutting performance.

Bosch DCB1072 Daredevil Circular Saw Blade: The final blade included in our list, the Bosch DCB1072 Daredevil Circular Saw Blade. Now this really is a great alternative for cabinet plywood. The 72 teeth allow it to cut through basically any thickness of plywood, and the diameter is a sizable ten-and-a-quarter inches. A nice feature of this blade is that its special design also limits noise and vibration, which means you can feel safe while running it during your projects.

All three of these blades have their benefits and drawbacks when it comes to cutting plywood. This will be largely dependent on size and thickness of the ply you are using, as well as how rough or smooth your project requires. However, with this said our top choice continues to be the Diablo D1050X Circular Saw Blade. It is a durable, all-purpose blade that can cut through nearly any plywood you throw at it and serves as an excellent option for multiple DIY projects.

Things to Consider When Looking For The Best Circular Saw Blades for Plywood The dimensions of the bladeNumber and shape of teethType of material used to create blades The bigger sized more teeth blades are most ideal for thick plywood, and the fewer smaller toothed blade types works best with thin ply measurement. Also, the teeth design also matters because it will influence how good your cuts are.

Our manufacturing facility covers more than 10 000 square meters and is best circular saw blade for plywood with cutting-edge machines This infrastructure gives us the ability to fulfill orders efficiently and with high quality We strictly control quality processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined for maximum precision

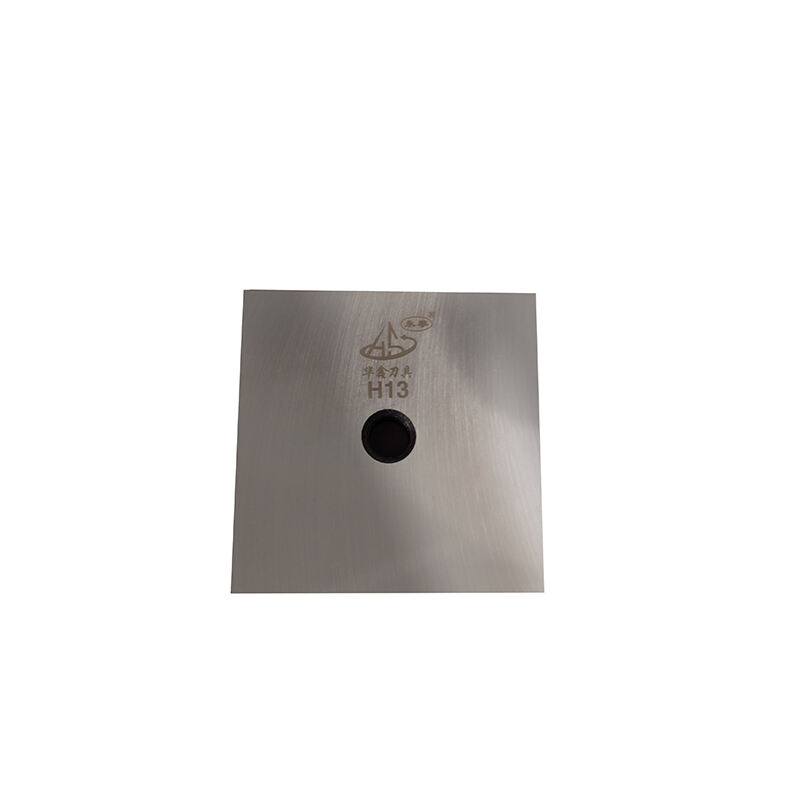

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a best circular saw blade for plywood in Nanjing City, Jiangsu Province, China. We specialize in the production of a wide range of mechanical blades, including crusher blades, wood chipper blades, shredder blades, and the granulator blades. Our expertise is in customizing and manufacturing the blades to meet customer requirements, utilizing advanced CNC machines grinding machines, heat treatment furnaces, milling machines, lathes and sawing machines.

Quality is a best circular saw blade for plywood at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We implement rigorous quality control procedures throughout the production To enhance durability and performance We use premium alloy steels specifically designed for tooling applications We also employ the latest techniques for heat treatment using vacuum and deep cooling techniques Our commitment to quality is apparent in our product's abrasion resistance toughness and extended time of service which puts us at the top of our industry

best circular saw blade for plywood production each blade undergoes meticulous inspection using electronic calipers for verification of dimension precision as per the technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure conformity to high quality standards These tests ensure that our products always meet or exceed customer expectations