Did you even touch a saw? A saw is a powerful and useful tool that can be used to cut wood, metal or even plastic. The way that it can perform its function is amazing. However the basic fact that does not come to your mind is maybe the blade you are using? The best skill saw blade can make your saw an even better performer, and projects easier to finish!

A skill saw is a type of round and very fast spinning blade. The spinner is the part of a CNC machine that spins and thereby makes it possible to cut or contour through materials much quicker, more cleanly than when done by hand with plasma torches. Skill saws are perfect for working on craft projects as you can cut straight lines and competitive angles. Having the best skill saw blade can provide you with power and precision that allows smooth clean cuts to be made every time. That way, it will be neat and professional!

One of the most indivertible points that help to make any skill saw blade strong as well as useful will be size. A larger blade can go through thicker materials, which is really useful for bigger projects. But aside from size, what else is important? The teeth design and the shape of the blade are also significant in defining how perfectly it will slice different substances. The size and the design combined create quite a stress on the blade that justifies its sharpness for what you need to cut.

Well, how do you decide which blade suits your requirements? Actually it depends on what you are going to cut. If you are cutting wood, a blade containing many sharp teeth set close together is advisable. This is the design that will allow you to make a neat and burr-free cut so your wooden pieces look perfect.

However, if you are cutting metal or plastic materials then use a blade which has fewer teeth and spaced farther apart. Those materials are more difficult to chop through so the blade needs additional room in order to navigate properly. Selecting the best blade to use on different materials can greatly enhance your cutting experience and success!

When cutting a piece of material using a skill saw, it is vital to ensure that the blade is flush with the material at all times. Indeed, aligning properly will ensure straight cuts to give a polished appearance in the end. Not to mention, always cut at the appropriate speed and amount of pressure. At the same time, trying to force the blade through by using too much strength can damage both your working material and the VC shears so know your limits!

When you need to do an excellent job sawing and are serious, then go ahead with the more skillful blades; which may be what is needed if any at all. The right blade can make the difference between whether your saw quickly wears out or performs well, and true. If you are a fan of working with tools at all, razor investment is always wise.

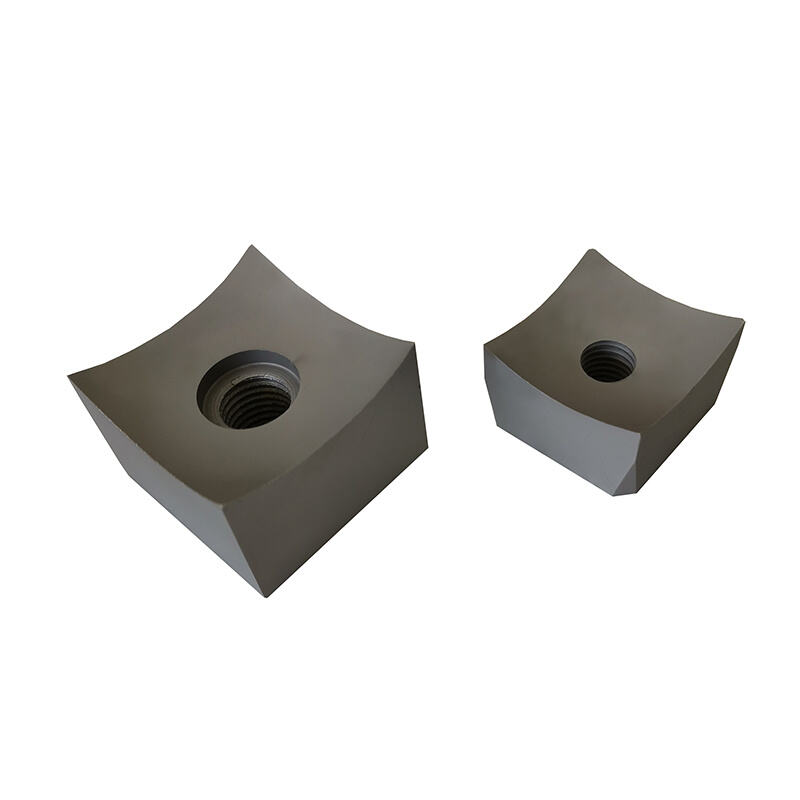

Each blade is thoroughly inspected using electronic calipers after production to ensure that it conforms to best skill saw blade We conduct hardness tests after heat treatment to ensure compliance with stringent quality standards This ensures that our products satisfy or exceed expectations of customers

best skill saw blade A manufacturer with specialized capabilities, is located in Nanjing City, Jiangsu Province, China. We specialize in making various types of mechanical blades including shredder, crusher and the granulator. We are experts in modifying the blades we manufacture and modifying them according to the particular demands of our clients using advanced CNC equipment as well as heat treatment furnaces.

Our factory is over 8 000 square meters and is outfitted with the most advanced machinery This best skill saw blade gives us the ability to fulfill orders efficiently and with high quality We adhere to strict quality control measures ensuring that raw materials are of the highest grade and that every blade is subjected to CNC milling to achieve the highest precision

Quality is a top priority Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We use rigorous quality-control procedures throughout our production To enhance durability and performance we best skill saw blade high-quality alloy steels that are specifically designed for tooling applications We also employ the latest vacuum heat treatments and deep cooling processes Our dedication to quality is evident in our products' abrasion resistance toughness and extended service life putting us at the top of the industry