This is obviously essential if you enjoy woodworking and therefore use a skill saw to cut plywood on a regular basis. Below are some of the simple and effective plywood cutting tips that can help you improve your skills. After reading the points in this article and getting some practice, doing a really good job with each of your cuts will soon become second nature.

To begin with, make sure you keep your workspace nice and tidy Keeping a neat and tidy workspace, which is an inherently positive habit will allow you to work quicker as well help in finding the tools that are required. In addition, a tidy space eliminates the likelihood of accidents. I never want to accidentally trip over something or cut myself open because of a crowded room. So spend a couple minutes cleaning up where you cut.

And then finally, you're going to want to inspect your skill saw blade for sharpness and other factors. With a weak knife, you will see it scratching the plywood and appearing like it is about to tear apart instead of produce a tidy slice. Even if you are using a tree shear to prune branches (vs branch clipper) not having a sharp blade will limit your ability. It is always advisable to check your tools before starting out.

Using a scrap piece of plywood to practice cutting is good! You have to try doing the same by taking a spare piece of wood which is not going to damage at all. It gives you time to get a feel for what the saw is like and allows you some confidence. It will help you get some better cuts in when working on your real project.

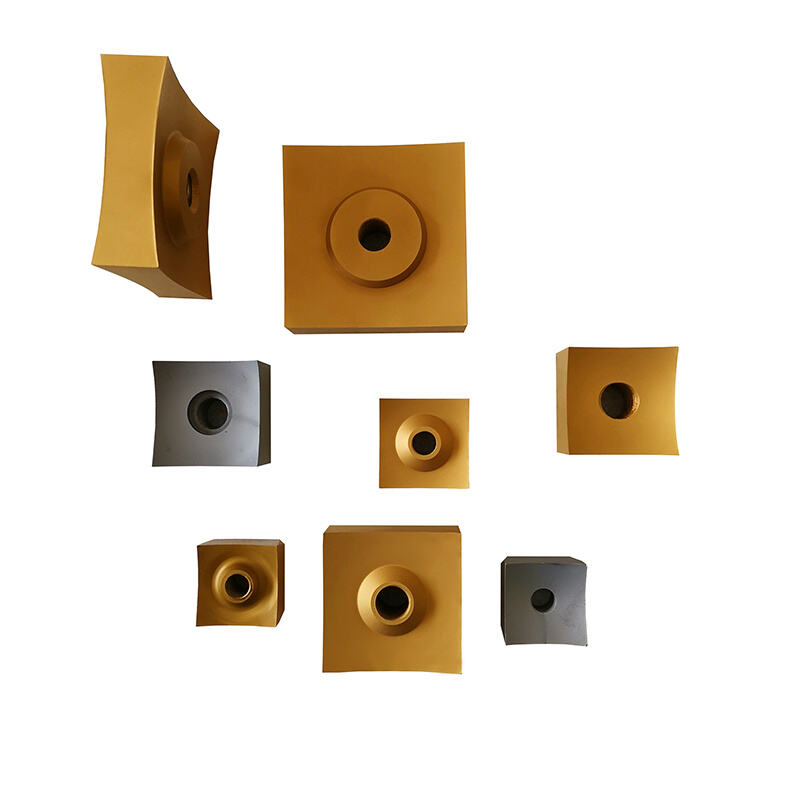

If you are looking for a good cut on your ply, pick the right skill saw blade. While choosing a blade, there are several things that you should consider like the number of teeth in it and its kerf as well as arbor. The number of teeth is also significant because the greater those are, more thorough that would be your cuts. To get a clean and smooth finish, the best blade for you is one with more number of teeth.

Take into account the blade thickness as well. The wider blades allow for more accurate cutting of heavier sheets of plywood, while the thinner ones are perfect for making precise cuts with lighter gauges. Finally, ensure that the arbor dimension of the blade suits your ability saw. In case of mismatch, you cannot fit the blade correctly.

Thickness of the blade also matters. A wider blade is used on thicker plywood. A thin blade, on the other hand would be ideal for thinner plywood: it does not get stuck pulling thicker materials through and requires less power to eat away at material.

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in best skill saw blade for plywood, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

Each blade is rigorously examined using best skill saw blade for plywood at the time of production to ensure it is in conformity to technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure compliance with high quality standards These tests ensure that our products meet or exceed the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd puts top priority on quality We employ stringent quality control methods throughout the process of production In order to increase durability and best skill saw blade for plywood We use premium alloy steels designed specifically for tooling applications We also employ the latest vacuum heat treatment and deep cooling techniques We're proud of our dedication to quality which is evident in the toughness and abrasion resistance of our products as well as their extended time of service

Our manufacturing facility covers more than 10 000 square meters and is best skill saw blade for plywood with cutting-edge machines This infrastructure gives us the ability to fulfill orders efficiently and with high quality We strictly control quality processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined for maximum precision