Did anyone ever wonder how those woodwrokers handle their woodworking projects for them to look su much neat and perfect? The secret is they use some tools! There are many other tools which carpenter can use but electric saw blade is one of most important tool. The tool is a reciprocating saw, the blade an electric helmet The utility knife is a favorite of many carpenters as they allow for straight and neat cuts in materials such as wood, plastic, metal.

When using an electric saw blade, it is also very important to choose the right one according to They type of material you are cutting. If you are cutting metal, for instance, a weaker blade will not survive as long-a stronger one used to cut wood. Using the right blade will allow you to cut more efficiently and leave a nice finish on your project.

When you are working with wood or other materials making straight and accurate cuts is crucial. To gain this, you demand a charged electric literal saw. A good sharp edge can handle tough cutting jobs without breaking or getting dull fast. It helps you to continue your work on the project, and will not have to change blades so frequently.

If you prefer a robust electric saw blade, then choose attributes which make its design long-lasting. Blades with a carbide teeth or having high-speed steel body, is just one example of the blades which are best suitable for you. These materials are incredibly durable and allow you to make clean cuts quickly.

A good example is when you are ripping hardwood; a blade with more teeth will do the job well and give cleaner cuts. Conversely, if you are cutting through softer wood a blade with less teeth is preferable. That is because using the right blade for your project can allow you to produce picture perfect lines that look much better to anyone who sees your work.

However, on occasion traditional blades simply do not leave you feeling entire or full. If you really want to increase your cutting performance try using a custom electric saw blade. A custom blade, however, can be uniquely tailored to fit how you like a cutting knife while being designed with your style and or specific logo in mind.

If you are considering a custom electric saw blade, have this information ready. You need to let them know what kind of material you will be cutting, the thickness and also type of cuts you are trying. This helps them manufacture a blade that will suit your projects the best and to give better results.

Every blade for electric saw is carefully inspected using electronic calipers after production to ensure it is in conformity to the technical drawings We conduct test of hardness post-heat treatment to ensure compliance with high quality standards These tests ensure that our products surpass or meet the expectations of our customers

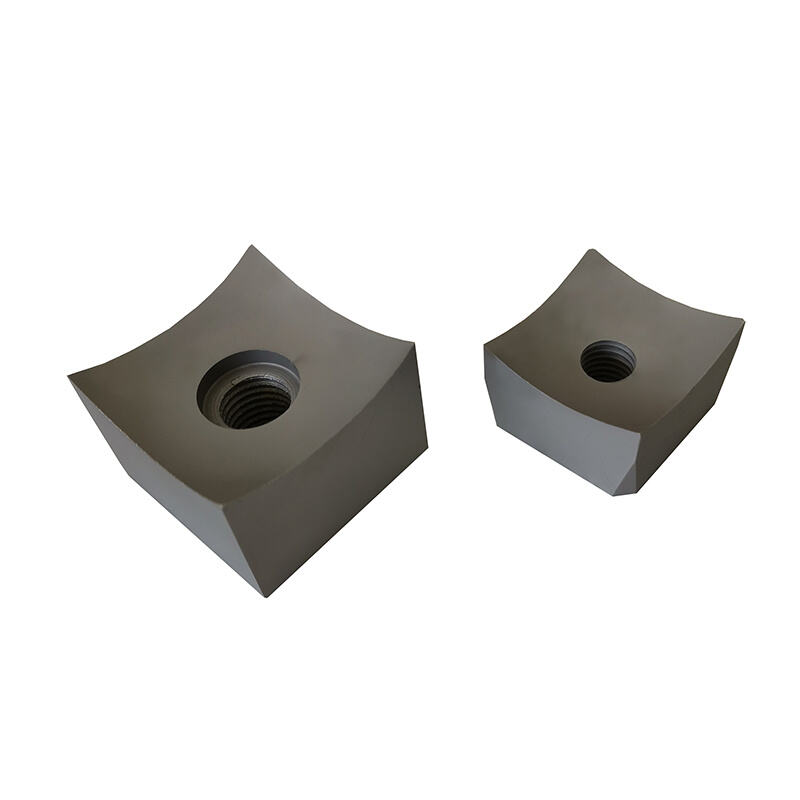

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a specialization in Nanjing City, Jiangsu Province, blade for electric saw. We specialize in producing various mechanical blades, including shredder crusher, and granulator. We specialize in customizing these blades and processing them to meet the specific requirements of our customers, by using the most modern CNC equipment as well as heat treatment furnaces.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd puts a high priority on quality We employ blade for electric saw throughout the production process To enhance durability and performance we use high-quality alloy steels that are specifically designed for tooling applications We also employ advanced techniques for heat treatment using vacuum and deep cooling processes Our dedication to quality can be seen in our products' resistance to abrasion as well as their toughness and long service life putting us at the top of the industry

Our manufacturing facility covers more than 10 000 square meters and is blade for electric saw with cutting-edge machines This infrastructure gives us the ability to fulfill orders efficiently and with high quality We strictly control quality processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined for maximum precision