The carbide saw blade is among the most widespread tools that both carpenters and builders depend on. They can cut through different types of material like wood, metal and plastic as well. Most people prefer to use it for the cutting task because of many advantages which make carbide saw blades wise choice,

Carbide Blades - Why Use? The first is that they are going to be very strong, and long lasting. This makes them very durable and it take a longtime before they get broken or need to bemore replaced. Carpenters and builders do not need to waste time, money replacing adhesives since they last for a very long span. The second aspect is that carbide saw blades are very sharp. Being so sharp, such bits are able to cut through all sorts of materials with the greatest ease and swiftness that facilitates faster work performance. Aside from that, due to their precise cut results carbide saw blade is best in the production. In practical terms, this implies that they will reduce truly neat and clean lines on the materials required for most any kind of building or carpentry project.

It is best used in combination with materials such as wood, metal or plastic that a Carbide saw blades can be cut by. That is because they are constructed from an extremely hard material called carbide. Carbide is made from things like tungsten and carbon that provide its strength. Saw blades made of this strong metal can handle a high pressure force when cutting. On top of that, carbide saw blades are designed in a specific way so they can cut through materials with little effort. It is designed to have blades that get shaped and angled in such a way it can easily glide through difficult stuff.

Carbide saw blades have the ability to provide very precision cuts which are one of their main features. Carpenters and builders, for example need their cuts to be the exact right size so that when they put them all together things fits like a dream. Carbide saw blades, with their level of sharpness and efficiency could only achieve this kind of accuracy. They can be used and relied upon when it comes to getting the perfect cut required for a carpenter work.

Carpenters and builders want to get the most out of each day, which is why they work with carbide saw blades. A faster cutting speed equates to saves workers time, or in other words that is efficient means by which these blades could cut through materials a lot quicker. This is particularly helpful in hectic professions where time costs money. In addition, the strength and durability of carbide saw blades mean that they do not have to be replaced very often. This saves carpenters and builders both time - and money - because as we all know, time is money... in any business.

Ensure you take the time to buy carbide saw blades and save yourself some trouble later on! The saw blade itself is not only efficient at passing through material but also delivers incredibly clean cuts. Not only are they far more durable, these products will get their worth over time without the need for replacements. This will save time and money on the long run. In general, carbide saw blades are a good investment for those who often find the need to cut material frequently.

Our factory carbide saw blades over 8000 square meters and is equipped with the latest machinery This facility allows us to effectively fulfill orders with high precision and quality We adhere to strict quality control processes to make sure that the raw materials we use are of high quality and that each blade is CNC-machined to achieve maximum precision

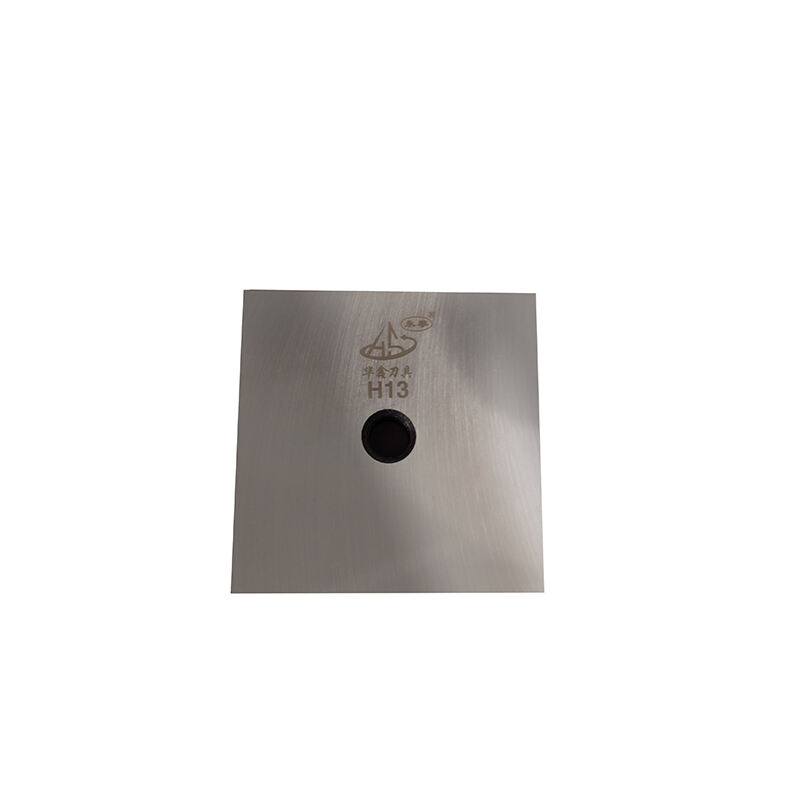

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd puts top priority on quality We employ stringent quality control methods throughout the process of production In order to increase durability and carbide saw blades We use premium alloy steels designed specifically for tooling applications We also employ the latest vacuum heat treatment and deep cooling techniques We're proud of our dedication to quality which is evident in the toughness and abrasion resistance of our products as well as their extended time of service

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a carbide saw blades with a specialization in Nanjing City, Jiangsu Province, China. We focus on producing an array of mechanical blades. These include crusher blades, wood chipper blades, shredder blades, and the granulator blades. Our expertise is in the customisation and processing of these blades to meet specific demands of the customer, utilizing modern CNC machines grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing equipment.

After production each blade goes through a thorough inspection using electronic calipers that verify carbide saw blades accuracy in line with the technical drawings After heat treatment we perform a hardness test to make sure that our products are in line with the highest quality standards These measures guarantee that our products surpass or meet the expectations of our customers