Are you a woodworker at heart? If you do, it's likely that a skill saw is one tool you employ for your projects. A skill saw is a tool made for cutting wood well and quickly. However, the blade mounted on your skill saw can lose its sharpness after you have made many cuts across one or more boards. In such circumstances, it is necessary to replace the blade for effective operation. How to change blade on skilsaw in 5 easy steps Learn how To Change Your Skill Saw Blade In Less Than 1 Minute!

This is a simple process that should take you no time to get done if you just follow the easy steps. Of course make sure to first double check that your saw is unplugged. It helps in avoiding accident while you are trying to meet your expectations. Afterward, you have to remove the old blade. To remove it, unscrew carefully and pulled out slowly. I will only state that this blade may be sharp, so handle with care. This is where you replace the old blade with a new one. Place the new blade into the saw and check that it is tight in place with no play When this is in place, you will have to make sure that the new blade is screwed in tightly. Last but not least, stuff all the allen-head bolts you removed for final assembly of your skill saw after it has been put back together; plug it in and start cutting wood again.

Now that you learned how to change your skill saw blade, go upgrade some of your woodwork and take things to the next level with fear! This makes the wood far more easier and quicker to cut when using a sharp, new blade. This gives you the ability to make more accurate cuts so that your finished projects turn out better. Regardless of whether you work on a birdhouse, shelf or anything else made from wood a sharp blade will soon have an impact in the appearance of your final product.

If you use saw blades which are dull, this can become very annoying. A dull blade will bog you down, and double the time it takes to complete any of your woodworking projects. For this quick little blade change, kiss those dull blades goodbye! By changing your skill saw blade routinely, you can help keep your saw in good working order. So save yourself both time and hassle on your next woodworking project. If you have good tools, and keep them sharp for the season length or crop wise then it provides a very smooth functioning operation working with our style of gardening.

Changing a skill saw blade is something that if you can embrace and get some practice in on will become second nature to you. Over time, and by doing certain exercises (explained previously), you will get better at this. You could soon be changing out your blade in five minutes or less with little to no headaches. This ability is good for keeping your projects running fine so you can worry less about the tools and more on woodworking.

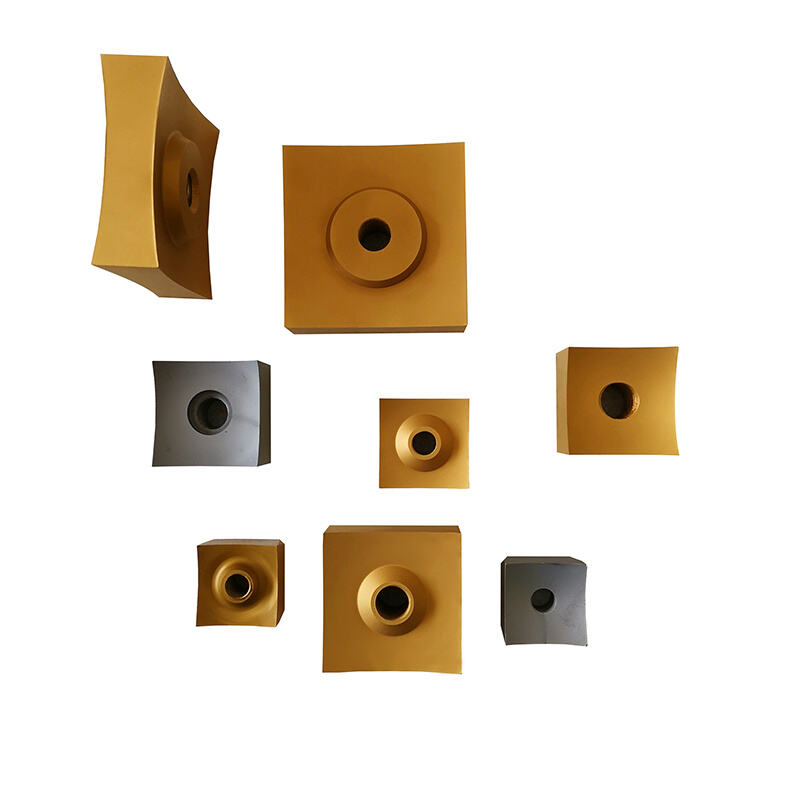

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in changing a skill saw blade, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

After production each blade is changing a skill saw blade with electronic calipers for verification of dimension precision as per the technical drawings After heat treatment we conduct a test of hardness to ensure that our products adhere to the highest standards of quality These tests guarantee that our products are able to satisfy or exceed expectations of customers

Our manufacturing facility covers more than an area of 8 000 square metres and is equipped with cutting-edge machines This allows us to efficiently changing a skill saw blade orders that require high precision and quality We follow strict quality control procedures making sure that our raw materials are of the highest grade and that every blade is subjected to CNC processing to ensure precision

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place an emphasis on the quality of its We use rigorous quality control methods throughout the process of production In order to increase durability and effectiveness we utilize high-quality changing a skill saw blade specifically designed for tooling applications We also employ the latest vacuum heat treatments as well as deep cooling techniques We're proud of our commitment to high-quality as evident in the toughness and abrasion resistance of our products and their long service life