The material in which the circular saw blades are again used to cut is also a very crucial factor. For example, it helps us get wood to the shape we envisaged for our furniture. When we cut the basic hole, it is fencing and hard for cutting corners on your straight line Very good quality speedy steel functions very nice whenever reducing. This ensures we are able to get the proper results and fabricate the things that we require properly, accurately without any delay.

Having circular saw blade steel will help you to do quality cuts. So you can make things in the correct: sizes shapes that YOU want. High quality steel is also several times stronger — it can cut through more difficult things than normal and simply does not break down. Plus, unlike affordable steel great dies it lasts longer while used so then you dont need to replace them all the time. In the long run, this can cost your money and time as you have to buy new blades frequently.

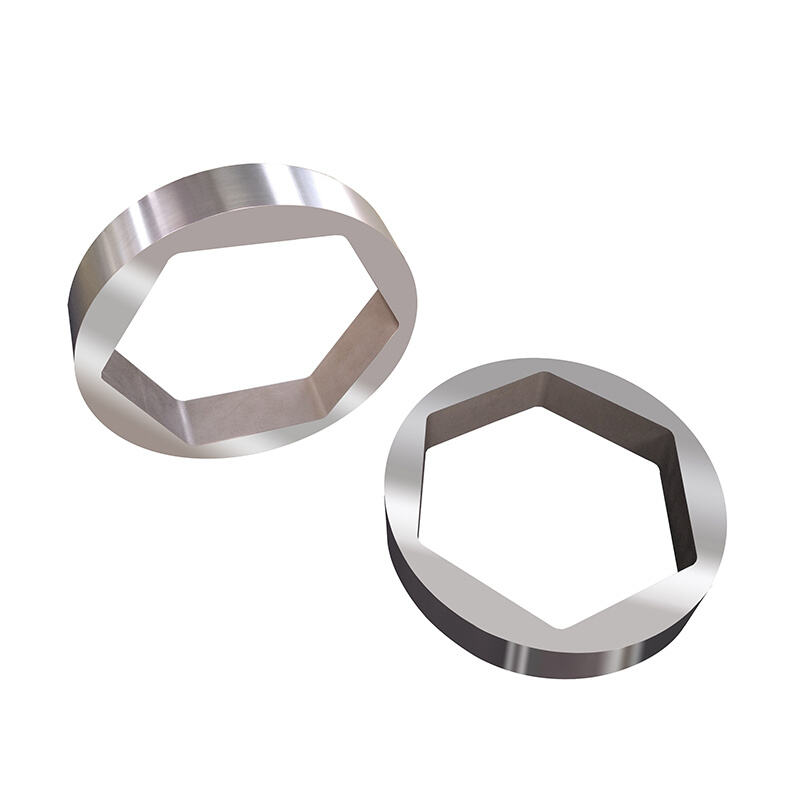

CIRCULAR SAW BLADE STEEL A mixture of several materials that are combined. Steel is the primary material used in making of these blades, allowing them to fully accomplish their job as they provide strength. Nevertheless steel can be modified by adding other materials to make it an improved material for cutting. Chromium, for example, is often added to provide increase strength that helps the steel take a racier without wearing out so easily. You can also include the Tungsten for strengthening the steel even more to be able to take on harder materials.

The material you are cutting is of real importance when it comes to getting through circular saw blade steel. The blade needs to have stronger steel in it, for cutting through weirder materials without the blades.The phrase on "harder" Aluminums then eg. And furthermore, a blade becomes very different with the thickness and size. A thicker blade can do tougher jobs and if the job too delicate, a thinner bladed will also be your best bet.

If you are trying to determine what circular saw blade steel is best for your needs, it's essential that you think about the type of material will be cutting. Strength of metal-free mediumNext, how strong the steel needs to be dependant on one you are working with. If you are cutting hardwood, for example, you would need a stronger blade than if the material is something softer like plywood. When we are buying any kitchen knife, the point about blade size and thickness is also an important thing for good work.

What steel to use for a circular saw blade is what determines the ability cutting clean. The blade has to cut through material as wide and thicker than the whole width of it, when you are working your saw. If the blade is weak or dull, that can result in poor cuts and frayed edges which are not ideal for a final piece. This, in turn would imply that the stuff you make may not have a tight fit or might not look as good as desired.

Carbide-Tipped Blades: a Quantum Leap in Circular Saw Blade Steel Technology Another type are premium carbide utility blades, where the steel includes bits of carbide to strengthen them and also make it harder wearing. A carbide-tipped blade can last up to 10 times longer than a regular circular saw blades. That translates to less replacements and more time cut, as opposed to shopping for new blades.

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd., a specialized manufacturer, is located in Nanjing City, Jiangsu Province, China. We are focused on the manufacture of a wide range of mechanical blades, such as circular saw blade steel, wood chipper blades, shredder blades and the granulator blades. Our expertise lies in customizing and manufacturing the blades to meet needs of our customers, using advanced CNC machines, grinding machines and heat treatment furnaces. milling machines, lathes and sawing machines.

Our circular saw blade steel covers over an area of 8 000 square metres and is equipped with top-of-the-line equipment This infrastructure lets us efficiently complete orders with a high degree of precision and high quality We adhere to stringent quality control measures ensuring that raw materials are of the highest grade and that each blade goes through CNC machined to ensure superior precision

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place top priority on quality We follow strict quality control procedures throughout the process of production This includes selecting high-quality alloy tool steel that is suitable for the specific applications for tooling using sophisticated circular saw blade steel and deep-cooling methods to increase durability and efficiency We are proud of our commitment to quality which can be seen in the abrasion resistance and toughness of our products as well as their extended duration of service

Every circular saw blade steel is carefully inspected using electronic calipers after production to ensure it is in conformity to the technical drawings We conduct test of hardness post-heat treatment to ensure compliance with high quality standards These tests ensure that our products surpass or meet the expectations of our customers