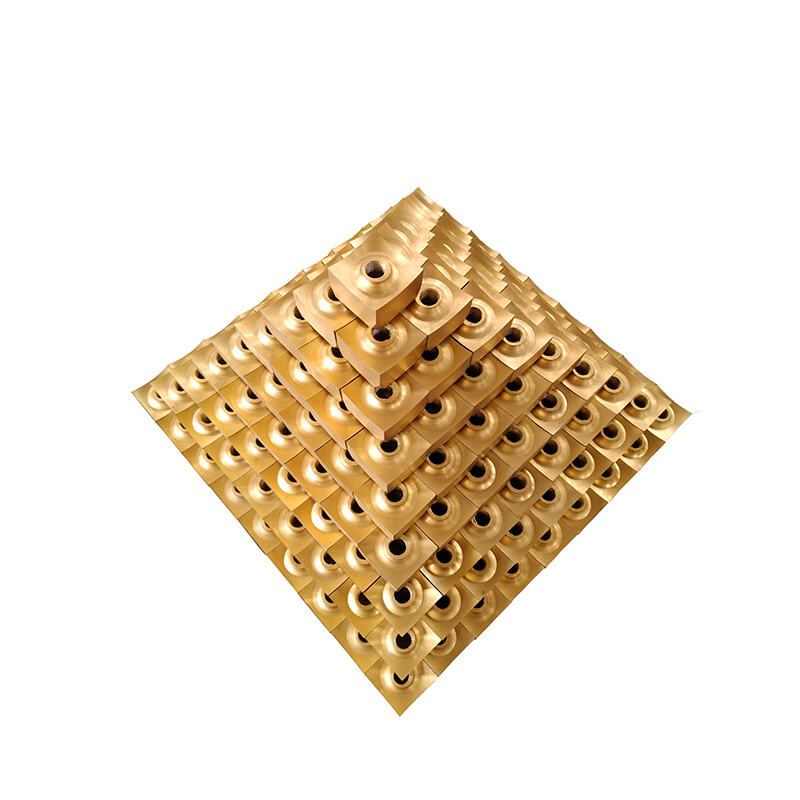

These are not simple saw blades; it is a set of carbide-tipped tooth air brush(clean ones) This is because they are made to penetrate heavy-duty materials, such as concrete, bricks, metal and also wood. These blades are different because of the tools sharp edge which allows workers to get their job done much quicker by a huge margin than using traditional methods.

There are a few tips you should follow to make sure that using your demolition saw blade produces the best results, and top of which is that it needs to be used with the right saw in combination with an operator who has been trained properly. And, the best saws for these blades are none other than a worm drive circular saw. This saw is known to give a maximum tooth for excellent control, power and simple cutting through tough materials.

A worm drive saw and demolition circular blade are the ideal combination for both quick: precise cuts when using it to cut through trusses, rafters: sheathing. But, always remember safety first! Remember to use the appropriate safety gear (ex: gloves, ear protection, glasses) when working. This can help you be protected and will make your experience in working better.

The biggest issue workers encounter with demolition saw blades is they wear out fairly quickly and need replacement often. This is likely to lead to a whole bunch of additional fees, which can be annoying. Bu with our long-lasting demolition circular saw blade, you can skip all those replacing the blades again and agin!

All our demolition circular saw blades are built to last longer than the average saw blade. That will cost you less money on replacements, letting your focus to the work and not stressing over price of frequent Blade installments. You can complete more work without worrying about reaching for a different tool.

Tired of using manual tool that consume more time and effort to provide all functionality? If the answer is yes, then you will want to give some thought as to how long it takes for your demolition work. Use a circular saw blade (tiger tooth, not one full of chisels!), and you'll be blown away by how easy it is to make accurate cuts the first time.

Whether with a demolition circular saw blade or any other type, you can get very clean cuts in no time. The circular saw is better for cutting straight lines, and curved ones too, as well a hard to reach spots which I found very useful. That means your work will have the fastest and best looking finishing touches.

Quality is a top priority Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We use rigorous quality-control procedures throughout our production To enhance durability and performance we demolition circular saw blade high-quality alloy steels that are specifically designed for tooling applications We also employ the latest vacuum heat treatments and deep cooling processes Our dedication to quality is evident in our products' abrasion resistance toughness and extended service life putting us at the top of the industry

Our demolition circular saw blade covers over an area of 8 000 square metres and is equipped with top-of-the-line equipment This infrastructure lets us efficiently complete orders with a high degree of precision and high quality We adhere to stringent quality control measures ensuring that raw materials are of the highest grade and that each blade goes through CNC machined to ensure superior precision

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialized manufacturer located in Nanjing City, Jiangsu Province, China. We specialize in producing various mechanical blades like shredder, crusher and the demolition circular saw blade. We are experts in modifying the blades we manufacture and modifying them in accordance with the particular demands of our clients making use of the latest CNC machines and heating furnaces for heat treatment.

demolition circular saw blade production each blade undergoes meticulous inspection using electronic calipers for verification of dimension precision as per the technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure conformity to high quality standards These tests ensure that our products always meet or exceed customer expectations