Metal Shear Blade Sharpening: A Must for Proper Tool Maintenance. Huaxin provides professional cutting blade sharpening services for your metal shear blades. With focus on precision sharpening methods and quality results, we provide all your blade sharpening needs. Keep reading to learn the benefits of using our metal shear blade sharpening service, popular problems that occur due to dull blades and tips for solving them.

When you choose to work with Huaxin as your metal shear blade sharpening service, you get the advantage of several distinct factors. To begin with, our professionals know how to accurately sharpen metal shear blades. Decades of experience in industrial manufacturing allow us to know the importance of sharp knives when cutting. When you purchase our service, you can be assured that your blades will sharpened with aroundness and care.

And our metal shear blade sharpening procured is intended to be easy for you and efficient. We know that production downtime can be expensive, and so we provide fast turn around service for blade sharpening. We work with you, whether it's a few blades or box loads of blades, making sure that your project is on time and as smooth as possible. Selecting Huaxin for your metal shear blade sharpening means you will face less downtime and keep your production line working like clockwork.

your solution (Literally) Ideal for maintaining the performance and life of cutters, shear blades/guillotines our metal shear blade sharpening details are below If it can be drawn we can sharpen it. With our knowledge, cutting-edge technology and dedication to customer satisfaction we will deliver the quality results that will improve your cut operations. At Huaxin, we are a name you can trust for all of your blade sharpening requirements and see the difference it makes.

A different reason may be that you are not using the correct cutting methods which may result blade dullness. Not using correctly cutting method, too hard receiving or over thick material to cut would lead the blades work so hard and get abrasion easier. If left unaddressed this could result in permanent damage to the blades of your metal shear. Sharp blade and can avoid blade to fade too early by cutting the correct way.

tackling some of the metal shear blade dull problems is a task that will need proper maintenance, good cutting practices and also environmental care. By knowing how blades get dull and what you can do about it, you can keep your metal shear blades sharp and in good condition for a long time of cost-effective cutting operation. Trust Huaxin with professional blade sharpening that will put an end to your blade’s dullness and improve the performance of your knives!

Huaxin is recognized as one of the best metal shear blade sharpening service specialists in the industry. We have built a solid reputation on over 15 years in the business and work daily to ensure that all of our customers are satisfied with our file sharpening service. We specialize in all types of metal shear blades and can sharpen to your specifications, quickly and economically We service a variety of metal shear blades including different sizes and Tooth configurations.

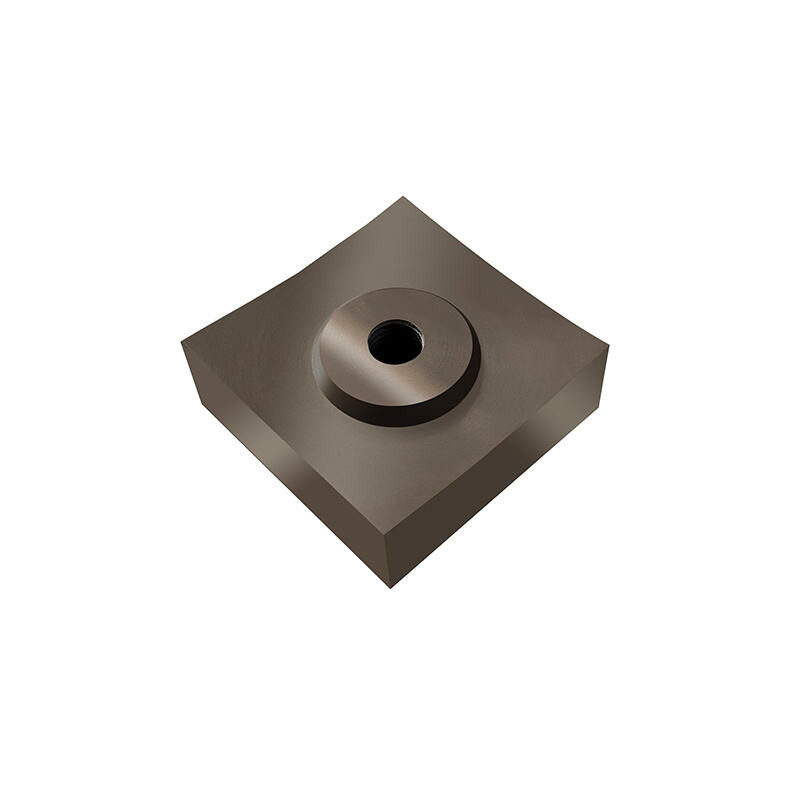

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialized manufacturer located in Nanjing City, Jiangsu Province, China. We specialize in producing various mechanical blades like shredder, crusher and the metal shear blade sharpening. We are experts in modifying the blades we manufacture and modifying them in accordance with the particular demands of our clients making use of the latest CNC machines and heating furnaces for heat treatment.

Our facility is spread over an area of 8 000 square metres and is equipped with metal shear blade sharpening This allows us to efficiently fulfill orders that require high precision and high quality We follow strict quality control measures ensuring that the raw materials we use are of the highest standard and that each blade undergoes CNC milling to achieve the highest precision

Every blade is carefully inspected with electronic calipers following production to make sure it conforms to the technical drawings We conduct hardness tests post-heat treatment to ensure conformity to the highest quality standards These measures metal shear blade sharpening that our products satisfy or exceed expectations of customers

metal shear blade sharpening puts a high priority on quality We employ stringent quality control methods throughout the manufacturing process To enhance durability and performance we use high-quality alloy steels specifically designed for tooling applications We also use advanced vacuum heat treatments and deep cooling techniques Our dedication to quality can be seen in our products' abrasion resistance durability toughness and longer lifespan placing us at the forefront in the industry