But, do you know what happens with Plastic Waste? It gets recycled! This nature of reprocessing is what enables people to pick up a single handled polyethylene terephthalate (pet) bottle which has been used once and have it become another new high quality industrial or commercial commodity item again. During this raw material recycling ocean process, the plastic waste is crushed into small pieces. But how do plastic waste broken into these small pieces? Well this is where plastic shredder blades are required!

Shredder is this machinery that previously here all kind of raw material will be shredding to very small or even granule size as per customer™s requirement. shredder plastic shredding blade, made in china configureTestingModule(); They specialize in shredding big blocks of plastic waste. The knife simply moves through the plastic like a hot butter. The shredder has blades that rotate at a very high speed and the plastic waste is thrown in it, these will slice the plastics into tiny pieces. It is an essential step to ensure that the plastic can be recycled into something else.

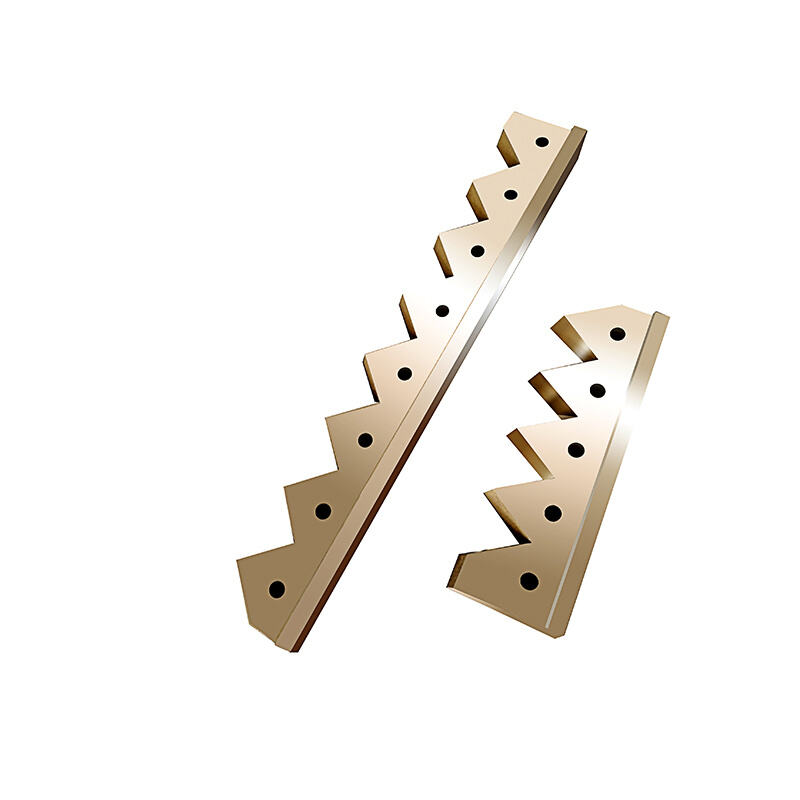

The shredder blades are made of the hardest material to make them last long. They also have to be proficient at adapting to the speeds and pressures used in plastic shredding. High-speed steel and tungsten carbide are the most popular materials that manufacturers forge these blades.

High-speed steel is a type of cutting tool; this allows the heat to endure. It is further built to experience a long while of staying strong and sharp, something you require in cutting. All things considered, tungsten carbide is a very hard material and great for cutting harder pieces. It is robust and durable with high tensile strength which why it suits best for shredding hard plastic.

The plastic shredder blades are available in many different styles and size. This is due to different types of plastic requiring a knife in order to be shredded. For instance, there are blades that work better with softer plastics like your plastic bags and wraps. Other blades are made for harder plastics such as PVC piping and bottle caps.

There are two major powers in the blade of a plastic shreddermachine, one is cutting capacity and other speed. Between the cutting capacity (plastic thickness a blade can cut through) and speed (how fast that single or dual blades spins around), These are two must-haves to start shredding anything.

As stated previously there are different blade designs to shred the various types of plastics and hence different type shredders for each plastic waste stream. Not only are the blades (its mold) easy to manufacture, but also top shredder knives generate some of the cleanest and sharpest cuts you need when processing soft plastic or hard plastics alike.

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialized manufacturer located in Nanjing City, Jiangsu Province, China. We specialize in producing various mechanical blades like shredder, crusher and the plastic shredder blades. We are experts in modifying the blades we manufacture and modifying them in accordance with the particular demands of our clients making use of the latest CNC machines and heating furnaces for heat treatment.

Following production every blade is scrutinized with electronic calipers for verification of dimension accuracy as per technical drawings We conduct hardness tests after heat treatment to ensure plastic shredder blades to strict quality standards These measures guarantee that our products are able to satisfy or exceed expectations of customers

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd It places the highest importance on quality We use rigorous quality control methods throughout the process of production This includes choosing the highest-quality alloy tool steel that is suitable for the specific tooling applications that utilize advanced vacuum heat treatment and plastic shredder blades to increase durability and performance We are proud of our dedication to high-quality products which is evident in the toughness and abrasion resistance of our products as well as their extended duration of service

Our factory plastic shredder blades over 8000 square meters and is equipped with the latest machinery This facility allows us to effectively fulfill orders with high precision and quality We adhere to strict quality control processes to make sure that the raw materials we use are of high quality and that each blade is CNC-machined to achieve maximum precision