As many of you who love woodworking and building stuff, we know that the right tools make our job more enjoyable. With the incorrect one, you're going to be fighting up a hill in your workshop. Types of Saw BladesThere are so many different saw blades in the market that it can be hard to determine which one you should get. This is exactly where Screwfix circular saw blades step in; make your cutting neat and clean with these amazing & efficient tools.

The most significant things to consider when picking out saw blades are one, how well the blade(s) cut and two:item lifespan. Blades that will cut clean and straight every time you use them. They are tailored to cut accurately, and so your pieces will be integral parts that fit well together for an overall clean finish. What more, they are sturdy and meant to endure extensive media use for a number of years without losing their potency-so you can be confident about the fact that your money is well-spent when investing in them.

There are various drill-cum-saw accessories and circular saw blades available at Screwfix for different jobs, materials etc. The first thing you need to know before buying the correct blade is what type of material that it will be cutting. For example, if you are working on hard wood then you will require a blade with more teeth so that it makes smoother cuts. A blade with less teeth is going to work better for that, on the opposite hand if you are cutting a soft wood like pine. Fortunately, you can buy a suitable blade from Screwfix for your project.

It is equally important to work fast and accurate for example in your workshop. Poorly-cut - and therefore useless, unless you can work around the error somehow or if the cut is made far enough into a longer/larger piece of wood to simply saw it off on your next try; in either case re-starting really hurts! This article reviews our top picks for circular saw blades, designed to provide you with a clean and effective cut while protecting the life of your woodworking projects. They also allow you to make accurate cuts, which are important if your project demands high-quality results. The right blades will make your job easier and allow you to be more efficient.

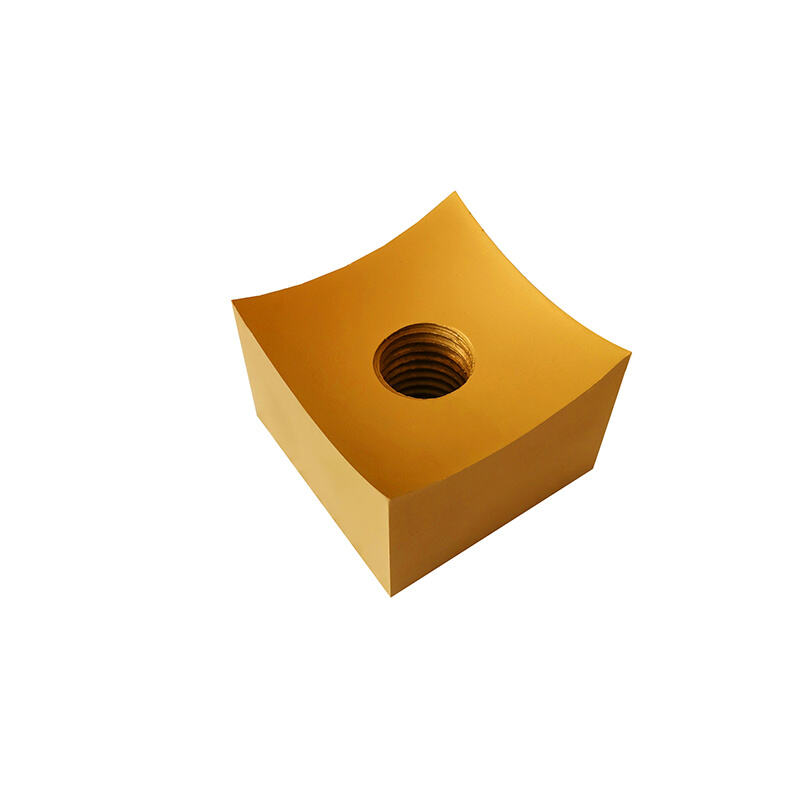

Screwfix have a wide range of circular saw blades in various diameters, number of teeth and for different cutting jobs. Screwfix Whether you're slicing via steel, wooden or plastic Screwfix have a cutter to fit your requirements. For instance, TCT circular saw blades are efficient for the cutting of Aluminum and non-ferrous metals plus also wood (particle board) that may have nails or plastic materials. Carbide teeth in these saw blades provide excellent cutting results without waste, bringing cost-effective material using for the users.

Quality is a screwfix circular saw blades at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We implement rigorous quality control procedures throughout the production To enhance durability and performance We use premium alloy steels specifically designed for tooling applications We also employ the latest techniques for heat treatment using vacuum and deep cooling techniques Our commitment to quality is apparent in our product's abrasion resistance toughness and extended time of service which puts us at the top of our industry

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a screwfix circular saw blades in Nanjing City, Jiangsu Province, China. We specialize in the production of a wide range of mechanical blades, including crusher blades, wood chipper blades, shredder blades, and the granulator blades. Our expertise is in customizing and manufacturing the blades to meet customer requirements, utilizing advanced CNC machines grinding machines, heat treatment furnaces, milling machines, lathes and sawing machines.

Every screwfix circular saw blades is carefully inspected using electronic calipers after production to ensure it is in conformity to the technical drawings We conduct test of hardness post-heat treatment to ensure compliance with high quality standards These tests ensure that our products surpass or meet the expectations of our customers

Our manufacturing facility covers more than an area of 8 000 square metres and is equipped with cutting-edge machines This allows us to efficiently screwfix circular saw blades orders that require high precision and quality We follow strict quality control procedures making sure that our raw materials are of the highest grade and that every blade is subjected to CNC processing to ensure precision