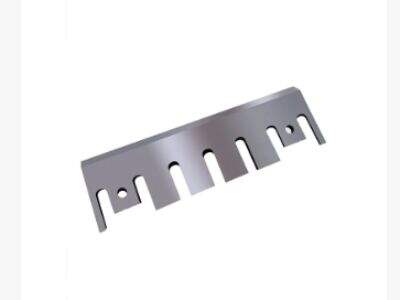

When it comes to a wood chipper, however, a lot of the credit for how well it cuts should go to the knife inside it. A wood chipper knife is an essential component of the machine which helps to cut the wood into tiny pieces. There are several factors which can impact how well a wood chipper knife functions, such as the type of steel it is made out of, how sharp it may be, and how it is put into the machine. What kind of details we should pay attention to when using wood chipper knives. We are an export company, and we always pay great attention to the details, to make good quality wood chipper knives.

How the Hardness of steal affects a Wood Chipper Knife?

The steel that wood chipper knife is made of is super important. Steel comes in many different varieties, each with its own strengths and weaknesses. Some steels can hold an edge longer but be more difficult to get back to sharp when they do get dull. Some steels may be less difficult to sharpen, but require it more often. Because we go with the optimal steel, that has the best of both worlds when it comes to being sharp, yet being easy to look after. This helps keep the chipper blades moving smoothly through the wood, and can help keep your knife in good condition for a longer period of time.

A sharp blade is important to getting wood chipped properly, even though it contribute to long term use

The blade's sharpness is the answer to good cutting performance. A blunt blade can cause the chipper to labor, which in turn can shorten its life. It can also result in a less clean cut, which is not what you want. We are just reminding our customers to keep a sharp blade. It’s an easy thing but has a huge impact on how well the wood chipper functions.

Make sure the knife is properly and tightly secured would enhance the cutting and also the Safety

There’s the way the knife goes into the wood chipper, too. If it’s not in it right, it can slip and not cut well. This can also be dangerous. We offer detailed instructions and sometimes even assist with installation to ensure you get the wood chipper blades set up correctly and safely. This is used to ensure the machine is working safely, and effectively.

Frequent sharpening and appendent inspection for damage can prolong life and cutting efficiency of a wood chipper knife

As with any tool, regular check-ups and maintenance are key. For a wood chipper blade that translates into keeping it sharp and watching for any damage. Small cracks or chips in the blade can become larger issues if they are not repaired early. Huaxin suggests setting a schedule for sharpening and inspections, depending on how much you use your wood chipper.

Blade design, size and shape as well as cutting edge angle all affect the overall cutting performance of a wood chipper

Lastly, the shape of the knife counts as well. The form and size of the blade and the angle of the cutting edge can influence how the knife enters the wood. Some may be more effective on certain kinds of wood or in creating particular sizes of wood chips. We design our knives with all of these considerations in mind, and try to offer a one-stop cutting solution for fine, medium, and rough woodworking applications.

There is much that goes into ensuring that a wood chipper knife works as it does. By taking care of these little things, Huaxin makes sure our customers have efficient and dependable machines for their wood chipping requirements.

Table of Contents

- How the Hardness of steal affects a Wood Chipper Knife?

- A sharp blade is important to getting wood chipped properly, even though it contribute to long term use

- Make sure the knife is properly and tightly secured would enhance the cutting and also the Safety

- Frequent sharpening and appendent inspection for damage can prolong life and cutting efficiency of a wood chipper knife

- Blade design, size and shape as well as cutting edge angle all affect the overall cutting performance of a wood chipper

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV SR

SR SK

SK VI

VI MT

MT TH

TH TR

TR FA

FA AF

AF GA

GA CY

CY LO

LO LA

LA NE

NE SO

SO MY

MY KK

KK