Plastic shredder blades have evolved tremendously over time. In the past, such blades were simpler and not extremely strong. But now, they are a lot better, thanks in part to companies like Huaxin. They are built from new materials in new designs that make them last longer and work better. That means they can shred more plastic before they break. It’s awesome to see how they have evolved to help us recycle more plastic and take better care of our planet.

The evolution of plastic shredder blade technology

In the early days, plastic shredder blades used to be pretty crude. They were constructed out of crude metals that would be easily worn. But as more people came to understand the importance of recycling plastic, the demand for better blades increased. Companies began to experiment with materials and designs. Now we have blades made from workhorse steel, with special coatings to make them tougher as well as last longer. A big part of this change has been led by Huaxin, who are working hard to make blades that allows us to recycle more effectively.

How Today's Shredder Blades Are Made of Plastic

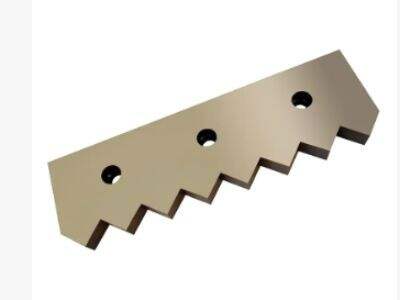

Its obvious that in the past compared to the past, the blade for shredder are now much more advanced. Designers employ computer programs to develop blades that can slice through plastic with ease and speed. These blades are sharp on both edges, with sturdy surfaces that do not dull quickly. Huaxin employs the latest technology to guarantee their blades are the best available fit and finish. That makes recycling plants more efficient, meaning they’ll work faster and waste less material, as every fan and mistaken bright wrapper are sorted out, which is good for both business and the environment.

Finding the Perfect Balance

Designing the optimal blade shredderis no easy task. It should be strong to cut through firm plastic but flexible enough not to crack. Huaxin tries to strike this balance. They experiment with types of materials and shapes to see what works best. Those we sometimes bulk up with extra metal or “enhance” with special ridges to make them stronger. It’s a complex challenge, but when you get it right, you create better blades that enable millions of people to recycle more, helping make a difference in their world.

Effect of Advanced Blade Models

Shredder blades’ new designs make a big difference. They will give extra smoothness and speed to the paper shredding process. This allows recycling plants to process more plastic, reducing landfills. Better blades also break less frequently, so plants don’t have to shut down for repairs or to replace them. This is time and money saving and leads to a more efficient overall recycling process. Huaxin’s superior blades are one half of the equation in this improvement, illustrating how great design can make all the difference.

How 3D Printing is Transforming the World of Plastic Shredder Blade Production

3D printing is one of the most interesting new technologies in blade making. This allows firms like Huaxin to produce blades that are the perfect shape and size. They can also create specially designed blades for specific recycling requirements. 3D printing also accelerates the all-important process of experimenting with new designs and materials in the quest to build better blades.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV SR

SR SK

SK VI

VI MT

MT TH

TH TR

TR FA

FA AF

AF GA

GA CY

CY LO

LO LA

LA NE

NE SO

SO MY

MY KK

KK