If you want to keep the crusher blade on good status and don’t damage when running the granules, you need to care it well. At Huaxin, we know the tight tolerances and abrasive nature of steel mills require you to use blades that will last. Here are a few suggestions and best practices to keep your crusher blades in top shape.

Maintenance methods of jaw crusher (1) the crusher jaw lubricating system is safe and reliable, the replacement of parts is convenient, and the maintenance workload is small.

Maintenance of a blade sharpness of a crusher is critical! Remember to wash the blades after each use to ensure they are free from any lint or glue. This prevents the buildup that can dull the blades. Keep the moving parts of the crusher well lubricated also to prevent deterioration.

How to Extend the Service Life of Crusher Cutter?

Use the crusher for its intended purpose. Do not smash material that is not suitable for the knife, so as not to damage the product. Also, ensure the blade is correctly positioned in the crusher. Out-of-alignment can also cause the blade to wear unevenly, thus shortening its life.

Best Way to Keep Your Crusher Knives Sharp and Durable

Keep the blades sharp using crusher machinery to ensure they are effective. A dull cutter needs to exert more force to get the same job done, and, in turn, can cause extra wear on the crusher and slow the production. Do not try sharpening the blade on your own - send it to a professional sharpening service.

Some Factors for The Prolonging of Crusher Blades Life

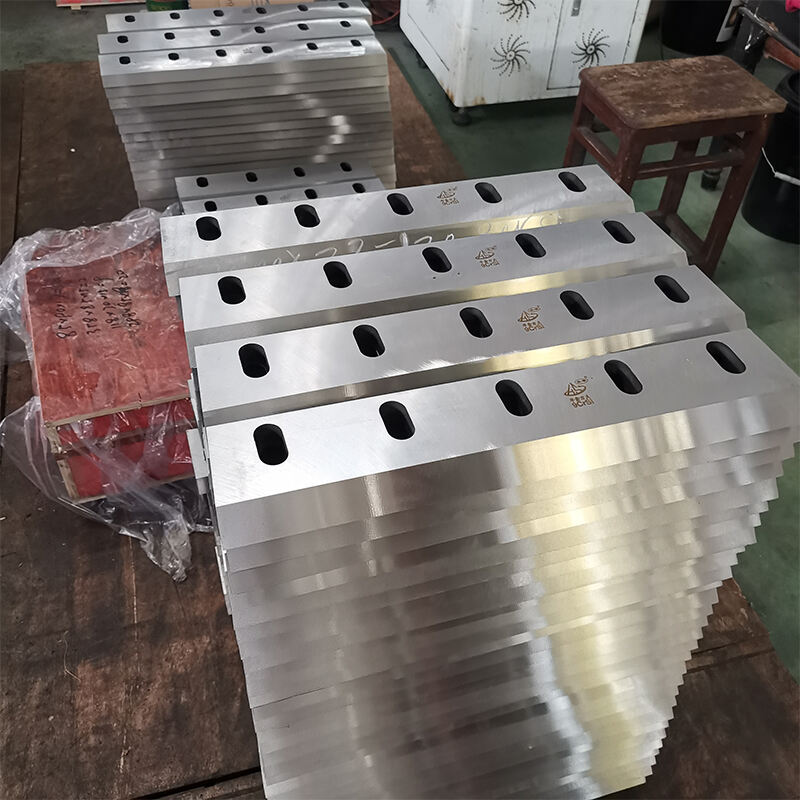

You should also consider the blade material. We (at Huaxin) use a grade of raw material to ensure the products can be used for a long time without the surface is getting damaged. Take in to consideration the surroundings in which the crusher is used. Also, blades have a shortened life due to the high and low temperature and the corrosive substances in the environment.

Measures to Prevent the Efficiency of Crusher Blades

Organize periodic monitoring of the crusher and blades so that you can catch any minor hitches before they blow out of proportion. Replace worn-out parts promptly. This also serves to maintain efficiency of the crusher and to prevent other component damage.

In this way you can make your crusher blades more wear resistant and longer service life, and meanwhile you can save more time and cost to get also improving your work efficiency.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV SR

SR SK

SK VI

VI MT

MT TH

TH TR

TR FA

FA AF

AF GA

GA CY

CY LO

LO LA

LA NE

NE SO

SO MY

MY KK

KK