When discussing shredder knives, one of the biggest considerations is hardness. Softer knives that will process these materials are more expensive and have a shorter life expectancy, and that’s very important in the industrial world, such as in our area (Huaxin). There is also a trade-off, because if the knife is too hard it will likely break and become brittle. Here’s a little information about what the hardness factor means and how it might be related to the durability of shredder knives and also how keeping the knives at the proper hardness might prolong their lives.

Effects of Hardness on The Service Life of Shredder Blades

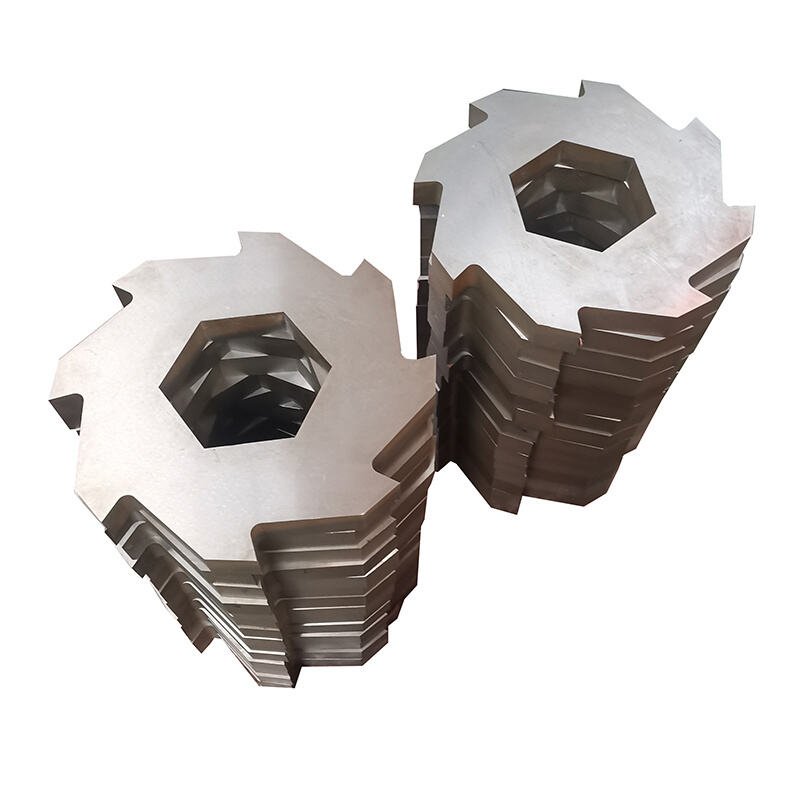

Involved with the hardness of shredder blades is the factor of how much this will allow them to be utilized without having to change them. If they are too soft, the business is licked immediately due to the softening matter coming in contact on a large scale with some hard material. However, if the hardness of the blade is way too great there is danger of chipping or breaking. The nation knows how to make a knife, they tell us at the Qingdao branch, and the hardness is given the steel of that quality found in rock and brittle as glass. At Huaxin they try to catch the medium as the only good knives are those which have sufficient hardness to get service, but not so much but what it breaks when it rams something hard.

Importance of Hardness in The Maximization of The Shredder Blade Life

A proper degree of hardness is how it is possible for our shredder blades to be utilized quite a while longer. This is very important as it is expensive as well as a nuisance to have to have new blades all the time. Huaxin makes it possible for the industries to save in time and expense by manufacturing blades at proper hardness, which means to the industries that they can operate with greater efficiency and economy.

The Impact of Different Hardness on Shredder Blades

At the present time, certainly it is desirable to have harder blades for greater convenience for different shredding operations. For instance, blades used for cutting soft wood do not require such hard blades as those used for cutting hard timber. Huaxin studies and investigates carefully for what purpose etc. the blade is about to be used and it modifies the hardness accordingly so that there is an even balance of hardness through the shredder, and medium between the hardness and softness are achieved so that each wood shredder blades performs at its best possible effectiveness on each different job.

The Hardness Influence on The Wear Mechanism of The Shredder Blades

The harder the blade the better protection against wear and tear. This means, too, that the blades do not dull very quickly, thereby readily preserving the useful cut for a considerable time. At Huaxin we give attention to that end that all of our blades may be lasting or reliable, which means that the customers get a greater value for their money spent on blades.

3 Ways to Keep Your Shredder Blades Sharp Longer

At Huaxin, we can perfectly harden our blades with a special treatment and special materials. Heat treatment and wise selection of alloy combinations is essential on shock absorption without sacrifice for performance. Our process through the production of these blades, carefully conducted, gives a long life to every blade, entails its receiving a perfect fit for performance.

With all processing machinery, the important thing is, that the hardness of the blade shredder is right if you wish these devices to run for any length of time and work efficiently. Huaxin, appreciates this to the fullest extent possible, for when it comes to blades you want tools continuous but they cannot be too hard because, otherwise, they break. This sort of philosophy stops customers from interrupting production too frequently changing blades in various machines.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV SR

SR SK

SK VI

VI MT

MT TH

TH TR

TR FA

FA AF

AF GA

GA CY

CY LO

LO LA

LA NE

NE SO

SO MY

MY KK

KK