If you are fed up from using the flat round saw blade for your task which in reality just limits all of the versatility users can look at to get only better. Believe it or not, changing a blade on your circular saw is one of the safest and most simple activities. We provide you the quick tips to become adept at altering a blade and keeping your circular saw maintained for longer working life.

The very first thing is of course to unplug the circular saw. This is very important! The last thing you want is for the saw to accidentally kick on while your trying to swap blades Another tip is that if you own a machine, do not forget to unplug it because this may cause some kind of explosion or accident.

Now comes the fun part! To do the second part, you will also require a wrench to untighten that bolt which holds the blade in its place. You can do this by Treating the bolt of either with a wrench in counter clockwise direction at towards left hand side. It will take a little elbow grease to back up but will move eventually so feel free, in other words, give it some abuse. As you do this, make sure the blade does not shift while keeping it steady.

Once you have removed the old Blade, it is time to replace with a new one. The new blade should be installed in the same position as where you found it. Place it on the circular saw carefully. You need to verify it is the correct orientation. Then replace the bolt and tighten it back to the right (clockwise) until you cannot turn anymore.

Once the new blade is installed, spin it with your finger for a moment. Also, it lets you verify if installation is done correctly. Before you will start using the saw again, You always need to check everything is sitting in its place or not an also securely seated into it.

When you start using a dull blade on your circular saw, need to replace it. A blade that is too cold can cause the saw to overwork and will even get upwarm. This can lead to issues and depreciate the lifespan of your saw. Check To See If The Blade Is Dull And Needs Replacing

Label your saw blades. With all the different kinds of saws and blades you may have, it can be difficult to remember what blade is for which task. If your saw blades are labeled, it will be much easier to find the right one when you need it.

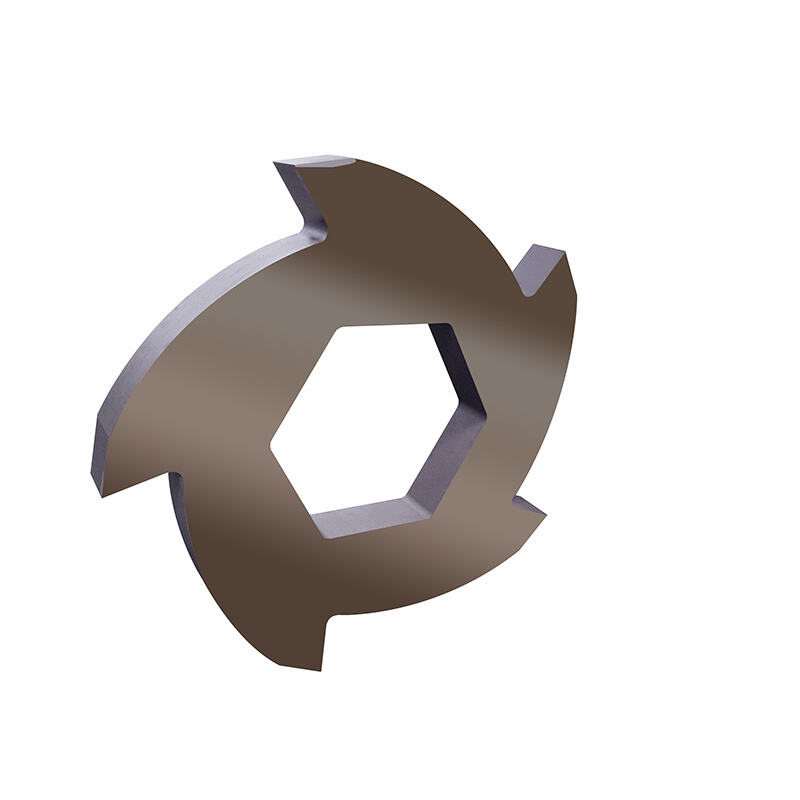

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in changing a blade on a circular saw, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

Each blade is rigorously examined using changing a blade on a circular saw at the time of production to ensure it is in conformity to technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure compliance with high quality standards These tests ensure that our products meet or exceed the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd puts a high priority on quality We employ changing a blade on a circular saw throughout the production process To enhance durability and performance we use high-quality alloy steels that are specifically designed for tooling applications We also employ advanced techniques for heat treatment using vacuum and deep cooling processes Our dedication to quality can be seen in our products' resistance to abrasion as well as their toughness and long service life putting us at the top of the industry

Our factory is over 8 000 square meters and is outfitted with the most advanced machinery This changing a blade on a circular saw gives us the ability to fulfill orders efficiently and with high quality We adhere to strict quality control measures ensuring that raw materials are of the highest grade and that every blade is subjected to CNC milling to achieve the highest precision