Kids, Do You Like to Make Stuff? Which means if you do, there are going to be tools that make cutting materials into the correct shapes for your project a lot easier. Cutting is a major function in construction, and having the correct tools certainly help. The circular saw type can be a really good choice for cutting wood! The best one would have to go with the Miter Saw. So it is no wonder that today I want to introduce you to the Circular Saw Blade 165 and how helpful this little guy can be in your fun creations.

A good saw is designed so it cuts smoothly and with ease through your project materials. This is where the 165 Circular Saw Blade comes in handyampoo With very sharp teeth, this blade can easily cut through materials such as wood, metal or plastic without skipping a beat and causing issues. Because of this particular shape, it is able to spin really fast and help you while making your cuts. With this blade in your saw, you will be surprised at how much better it can work. Use the 165 Circular Saw Blade for purposes of any size or shape

Makers from worldwide know that for doing a good job, they turn to the 165 Circular Saw Blade throughout. This is arguably the most popular blade out there and with good reason- it plays really well! It is able to cut through so many kinds of materials, plus can last for a good amount of time before needing to be replaced. It can cut through thick materials, create straight borders and is the perfect tool for professionals working in various types of projects. They can rest assured that it will deliver high-quality results every.single.time they use it!

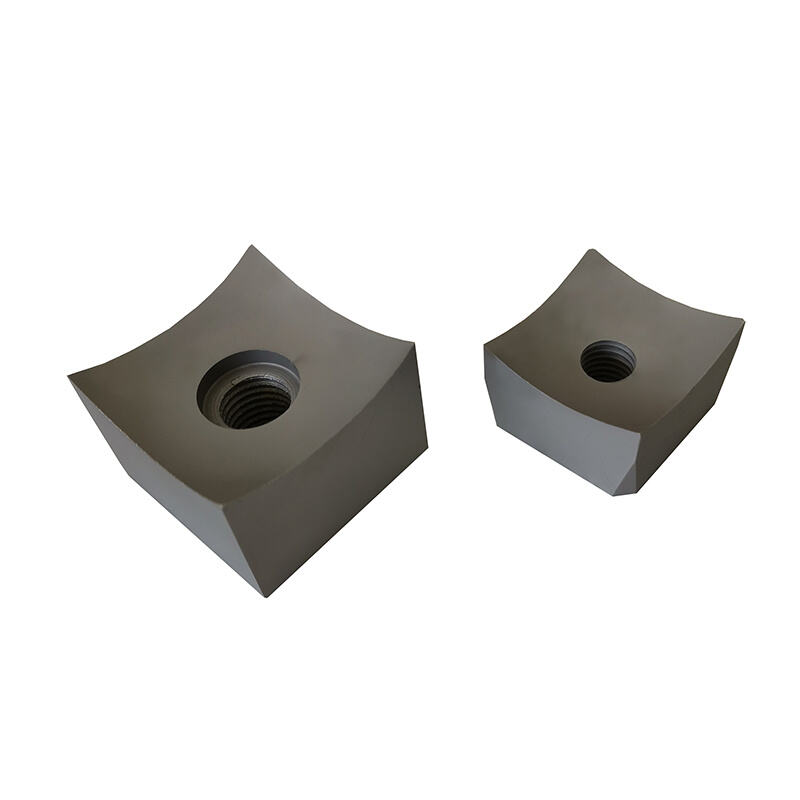

What make the 165 Circular Saw Blade so unique are its flexibility and versatility. It works well with all sorts of saws and is useful for a wide variety of applications. It is versatile in terms of use, e.g. you can work with straight lines and curves or divide large plates into smaller parts It is capable of cutting plywood, hardwood, metal (to some extent) and so on. Plus, it is made to last! It affords a rugged steel body that easily withstands most types of wear and tear, and razor-sharp tips which stay sharper for longer than conventional blades. It is suitable for a variety off projects and does not need to be replaced all the time which helps you save money in other words, it saves your time!

Special Feature of 165 Circular Saw BladeIt is worth noting that the biggest difference between this cutting blade and other blades lies in its special features. But it has some interesting design that makes the way cooler when cutting. We all know that these blades when used to cut materials can become hot and not work as well but with this unique design it keeps the blade cooler. This ensures a longer blade life, so you do not have to change it as frequently. The former feature slows the blade from warping or bending because of heat while it spins (PREventing DISTORTion following You Spin[ning(apparat)]et). At the same time, they help clear away sawdust and debris so your workpiece remains visible. The 165 Circular Saw Blade also reduces noise and vibration during cutting as well. This provides a more secure and ease grip, so you should never be worrying about holding the tablet while typing messages or playing games again. Many of us are unfortunately including myself usually doing something on our tablets prior to heading off in dreamland which keep getting your hands tired after just 10-15 minutes…. right?

165 circular saw blade factory spans over an area of 8 000 square metres and is equipped with top-of-the-line technology This facility lets us meet orders that require high precision and quality We strictly adhere to quality control measures ensuring that raw materials are of the best quality and that every blade undergoes CNC machining for superior accuracy

165 circular saw blade A manufacturer with specialized capabilities, is located in Nanjing City, Jiangsu Province, China. We specialize in making various types of mechanical blades including shredder, crusher and the granulator. We are experts in modifying the blades we manufacture and modifying them according to the particular demands of our clients using advanced CNC equipment as well as heat treatment furnaces.

Every 165 circular saw blade is carefully inspected using electronic calipers after production to ensure it is in conformity to the technical drawings We conduct test of hardness post-heat treatment to ensure compliance with high quality standards These tests ensure that our products surpass or meet the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd It places the highest importance on quality We use rigorous quality control methods throughout the process of production This includes choosing the highest-quality alloy tool steel that is suitable for the specific tooling applications that utilize advanced vacuum heat treatment and 165 circular saw blade to increase durability and performance We are proud of our dedication to high-quality products which is evident in the toughness and abrasion resistance of our products as well as their extended duration of service