When dealing with a blade shear, it always means you are going to cut through something like paper and fabric hence hair. It is an undertype of scissors, though large and very sturdy. The most common form of shears, are these blade-like shears that meet in the middle with a handle. The operation is very basic, Pull the handle out and it opens for you pushing on part of which drops down a razor blade. Squeeze in closer to either hand open or closed state – this all over again does your own cutting. So, they are beneficial in most jobs.

They are robust as they are made from heavy metal, the two blades and it works likes scissor. The blade that is sharpened on the sides can run through some of densest materials given a slight effort. The handle mostly in plastic or rubberized. This type material is more relaxing for the event that you are cutting as it improves griping of your shears. Safety lock: Some blade shears include a safety-lock on the other handle that can be engaged in order to hold both blades shut when not in use. This is a key safety function to prevent accidents.

Essential productivity tools for any professional, blade shears. Their most convenient use case is in tailoring, barbers and hairdressing (except for the final cutting). They are high in delivering with the cutting of many fabric types such as cotton, silk or denim. Tailors highly value precision cutting. Also, they have their mannequins with them now so they can make things to fit exactly how we would like. A pair of basic tools for barbers and hairstylists to help create stylish haircuts is blade shears. And, they are working with these shears everyday to make you look the way that makes them smile!

However, it should be noted that for your blade shears to always remain in good condition and continue working properly over time you need proper maintenance of sorts. Before you start purchasing new ceiling fan blades, try cleaning them to remove any dust and debris that have built up on their surface. It makes them run stronger. Next, Give the blades a slight oiling to keep them polished and prevent rust. Because they will ultimately rust and be useless for the work. And have the blades sharpened as needed too. and of course -- keep blade shears in a dry location. Add to it, keep them in a dry place and they not going t get rusted too which can give you the benefit of using these blades for many years.

The length of blades also varies making some very small which can be handheld and others such as electric, big. Some shears are only for hair, others work well with fabric. Choosing the appropriate blade pruning shear A barber or hairstylist might desire a much smaller shear that has one larder as well as another curved. That is what this design style allows. On the flip side, a tailor that needs to tackle thicker fabric might benefit from straight blade shears in a larger size. Additionally, take into consideration the weight of your shear. Fatigue The hand will get fatigued if you hold a heavy shear for an extended period of time

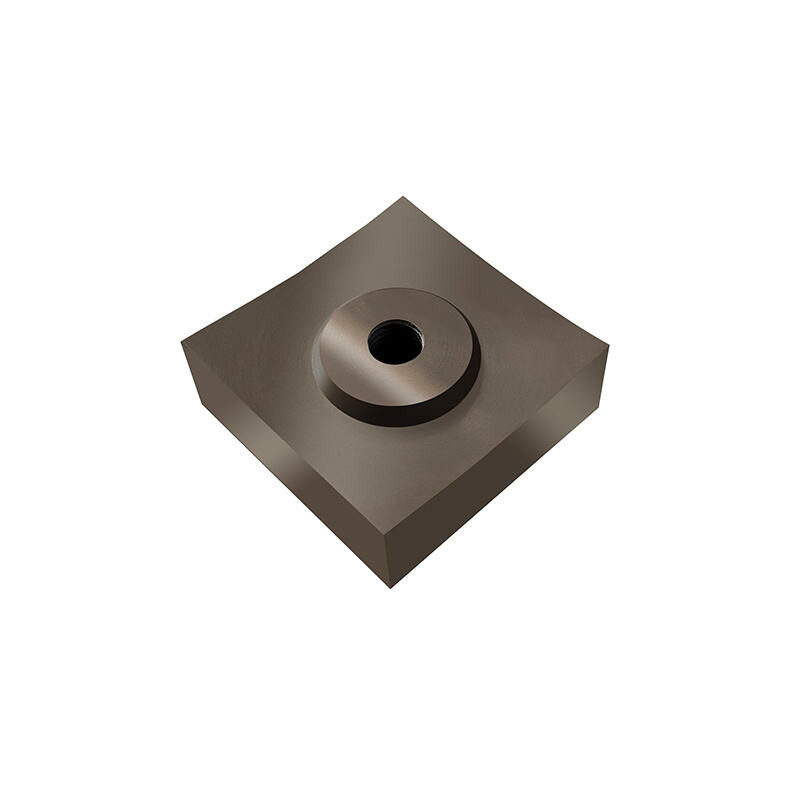

blade shear puts a high priority on quality We employ stringent quality control methods throughout the manufacturing process To enhance durability and performance we use high-quality alloy steels specifically designed for tooling applications We also use advanced vacuum heat treatments and deep cooling techniques Our dedication to quality can be seen in our products' abrasion resistance durability toughness and longer lifespan placing us at the forefront in the industry

Every blade is carefully inspected with electronic calipers following production to ensure it is in conformity to the technical drawings We conduct blade shear after heat treatment to ensure conformity to strict quality standards This ensures that our products will meet or exceed the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a blade shear in Nanjing City, Jiangsu Province, China. We specialize in the production of a wide range of mechanical blades, including crusher blades, wood chipper blades, shredder blades, and the granulator blades. Our expertise is in customizing and manufacturing the blades to meet customer requirements, utilizing advanced CNC machines grinding machines, heat treatment furnaces, milling machines, lathes and sawing machines.

Our factory is over blade shear square metres and equipped with the most modern equipment This allows us to have to process orders efficiently and with high quality We follow strict quality control procedures to ensure that the raw materials we use are of top quality and that each blade is CNC-machined to ensure maximum precision