If you are to make straight cuts in plywood the most significant is using a proper circular saw blade. Right blade helps with clean and tear out free cuts without damaging the plywood. If you use the incorrect saw blade, it can cause splinting or tear-out in your wood and ruin their project for looking ugly. So, let us give you some insights on what to choose the right blade that suits best when buying a circular saw blade for cutting plywood.

Sizes of Circular Saw BladesCircular saw blades are available in a variety of sizes by the length and number teeth that each blade has. There are specific goals each blade is tailored to and they have different strengths so pick wisely. The number of teeth on your blade should be appropriate for cutting plywood. Tooth count is the number of teeth. A blade that has more and smaller teeth will give a smoother cut But, they will also slow-down the cutting speed because of having more teeth if you need to cut a large number of plywoods. In this case, you may opt for a smaller number-of-teeth blade to cut time.

In order to get clean cuts with plywood, it is ideal that we keep the blade broader and use one having more teeth. An 80-tooth or 100-tooth blade slices through the ply with little to no tear-out, an ugly, shredded cutting edge that makes removal more difficult. This is of course, particularly relevant if you want your project to look nice. But if you need to make a ton of those cuts on plywood, consider using fewer teeth per inch. It's also faster than the other thin-kerf type of blade, which is handy if you are pressed for time or have a large volume of work.

The circular saw blade must be cut in a certain way to ensure proper cutting efficiency. Mark where you want to make your cut on the plywood first. This will serve as a guide that and your cuts should be set. Using a circular saw, score the line lightly after marking This first cut will give you a reference point for your blade and should reduce any tearout. Then, when you have scored it correctly with your box cutter or knife, go ahead and make a full cut after the scoring along that line in one continuous motion. This is the way to improve your work.

Plywood is a tough material to cut through, and it only gets worse with the wrong blade. But don't worry! With a good circular saw blade, plywood is one of the nicer materials to cut. Try to choose a blade with high tooth count and thin kerf MTX. By definition, the ma; he of cut that is taken off by your saw during damage-based cutting factories powered radially. It has a thin kerf to reduce waste and make more accurate cuts. Be sure to always follow the cutting line and score it before your final cut. Doing these simple steps will just make the whole process easier and you will get better results.

There are a variety of circular saw blades specifically for cutting plywood. These will often have a very fine tooth count, thin kerf teeth with special design features that give them backer material to reinforce the grain so it does not splinter or tear. The recommended for cutting Plywood Circular Saw Blade This will play an important role in helping you make the best of it and also make your efforts & time spend using plywood cutting easier.

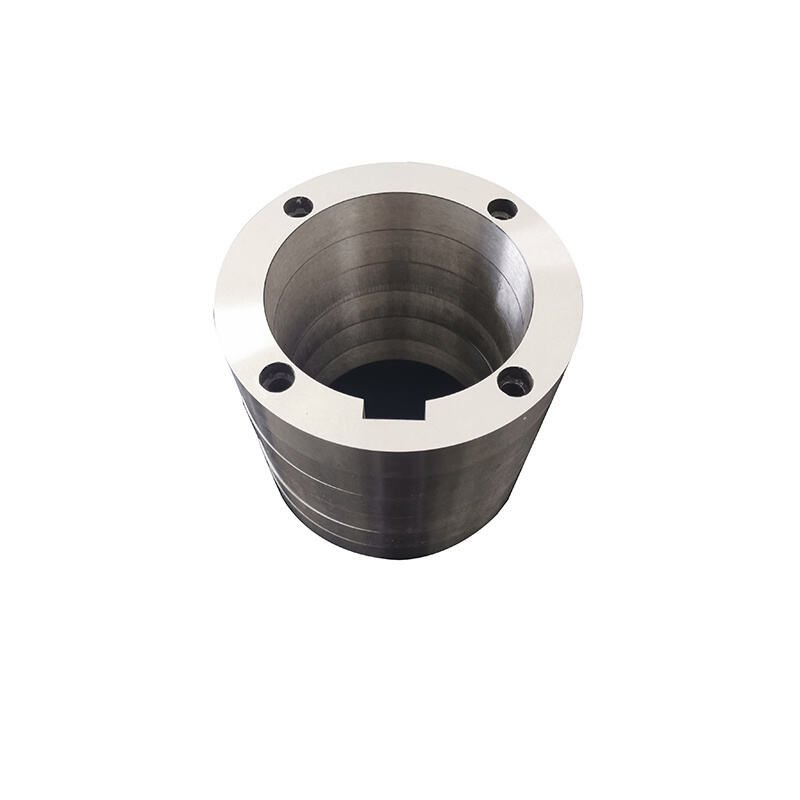

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialist manufacturer based in Nanjing City, Jiangsu Province, China. We are experts in manufacturing different types of mechanical blades including circular saw blade for plywood, crusher and the granulator. We are experts in modifying the blades we manufacture and modifying them to meet the exact requirements of our customers, making use of the latest CNC equipment as well as heat treatment furnaces.

After production each blade is circular saw blade for plywood with electronic calipers for verification of dimension precision as per the technical drawings After heat treatment we conduct a test of hardness to ensure that our products adhere to the highest standards of quality These tests guarantee that our products are able to satisfy or exceed expectations of customers

Our factory circular saw blade for plywood over 8000 square meters and is equipped with the latest machinery This facility allows us to effectively fulfill orders with high precision and quality We adhere to strict quality control processes to make sure that the raw materials we use are of high quality and that each blade is CNC-machined to achieve maximum precision

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd puts top priority on quality We employ stringent quality control methods throughout the process of production In order to increase durability and circular saw blade for plywood We use premium alloy steels designed specifically for tooling applications We also employ the latest vacuum heat treatment and deep cooling techniques We're proud of our dedication to quality which is evident in the toughness and abrasion resistance of our products as well as their extended time of service