Changing the blade on your circular saw from DeWalt, may be a bit daunting at first but fret not! It’s actually quite simple. Follow the specified recommended steps, And you will be able to take this as a task soon. Step By Step On Changing The Saw Blade

Before you do anything, though, ensure your saw is switched off and unplugged from the power supply. Its very important for you safety! This posting brief reminds you of always prioritize safety when working with any hazardous tools. Unplugging the saw will keep any unexpected start ups from occurring during your project.

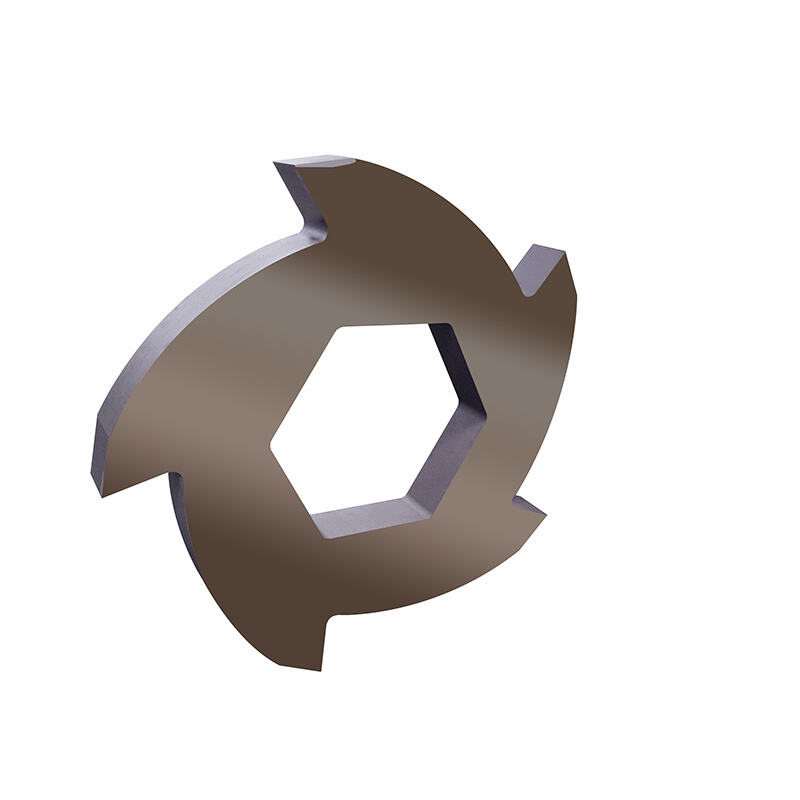

The next step is to remove the old blade. An arbor nut secures the blade. The nut you can locate in the middle of the blade. Grab a wrench if you have it and start turning the arbor nut to your left until you can get it loose enough to spin off. Then you just slide if off once its loose. This makes removing the old blade from your saw simple.

The next step in this will be placing the new blade on your saw's arbor. Note the direction that blade teeth are oriented. The teeth can only be facing in the direction that will cut — always forward. Due to the way that teeth work, it is extremely important for them to face in one direction and if they do not then cutting with a blade will be impossible. As you place the new blade on the arbor, position the arbor nut back over top of it then tighten it down with your wrench. When using the blade itself make sure it is tight enough that when you are cutting, the damn thing don't fall off.

You need to make absolutely sure of your measurements before you begin cutting. Always examine the blade to ensure that it is attached correctly and has not loosened. By following these steps, you can ensure that your blade will remain still without it being wobbly or loose — this is very important as a moving blade could put you in serious danger! If everything looks fine, then you can head back to cutting.

But even if this is not the case, you may have to change a few settings of the saw in order carve some other material. There are various types of materials that can be cut all using circular saw, every material requires some sort of special need in regards to adjusting your high-quality circular while cutting.

The blade on your saw can be dull, or damaged over time. If you realize it is doing this, then change the blade. If your saw is cutting fine, then it will not cut you instead which could even cause an accident.pyplotter Unintentional errors are greatly reduced by keeping the blade changed.

Our facility is more than 8000 square meters and is equipped with the latest machinery This allows us to effectively fulfill orders with a high degree of precision and high quality We strictly changing blade dewalt circular saw to quality control measures to ensure that our raw materials are of the highest standard and that every blade undergoes CNC milling to achieve the highest precision

changing blade dewalt circular saw production each blade undergoes meticulous inspection using electronic calipers for verification of dimension precision as per the technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure conformity to high quality standards These tests ensure that our products always meet or exceed customer expectations

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a specialization in Nanjing City, Jiangsu Province, changing blade dewalt circular saw. We specialize in producing various mechanical blades, including shredder crusher, and granulator. We specialize in customizing these blades and processing them to meet the specific requirements of our customers, by using the most modern CNC equipment as well as heat treatment furnaces.

Quality is a top priority Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We use rigorous quality-control procedures throughout our production To enhance durability and performance we changing blade dewalt circular saw high-quality alloy steels that are specifically designed for tooling applications We also employ the latest vacuum heat treatments and deep cooling processes Our dedication to quality is evident in our products' abrasion resistance toughness and extended service life putting us at the top of the industry