Have you ever heard of the term concrete crushing machine? Its this big machine that is used to cut chunks into more manageable pieces. Those small pieces are very handy for many things. Find out more of these amazing machines help us in this post, keep reading!

Construction debris looks like those big pieces of concrete. This debris could also cause issues and get in the way of other parts. Can be difficult to move; takes space If you own a crusher however, it can break all of that down into manageable parts. It is easier to manage and shift. The concrete does not have to be a burden, it can actually serve as something beneficial!

Crushing Equipment Processing ConcreteLimitConcrete plant in a concrete, reducing by harmful materials only collapse ash bricks produced not waste.

Bet you didnt know this, but concrete waste can actually be turned to something fruitful and useful! Special crushers are used for this procedure. The waste is taken by the machine and gets crushed into tiny pieces to use it back again. One way to do so is by using it as a solid base for new roads or other building projects, given that the smaller concrete pieces will help provide structural integrity. This not only cuts down on waste, but also saves money and resources!

When your job needs to be done quickly and efficiently, you need a powerhouse. The machines are built to crush concrete into sizes that can be used in only a matter of minutes. Such swiftness is very relevant when you are required to complete a job on time. The faster you can break the concrete, and get on with your project!

In other cases, one has a lot of concrete at once to crush. This is physically a tough job that will take you ages without the proper tools. This task is almost impossible, but with new and improved machines this job can be done relatively very easily. The technology in these machines is simply first-rate and commendable, they have full capability of crushing concrete at very high speeds thus making the job a whole lot easier.

If you are looking to enhance your efficiency and increase job productivity, then a powerful concrete crushing machine is right up there. Let us see the process of making them. Moreover, these machines are customised to provide more weight carrying capacity and crushing power which in turn enables it crush loads of concrete faster through a span of time. Good at what they do — They are able to be productive and efficient so you can get more done with your day. It is an excellent way to streamline your workflow and produce better results.

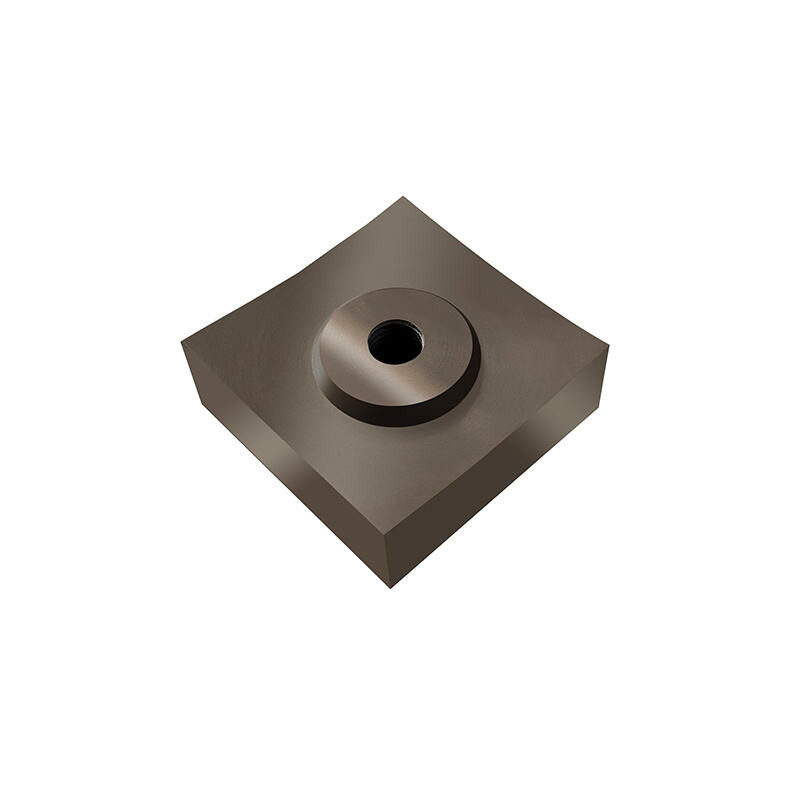

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd It places the highest importance on quality We use rigorous quality control methods throughout the process of production This includes choosing the highest-quality alloy tool steel that is suitable for the specific tooling applications that utilize advanced vacuum heat treatment and concrete crushing machine to increase durability and performance We are proud of our dedication to high-quality products which is evident in the toughness and abrasion resistance of our products as well as their extended duration of service

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a concrete crushing machine in Nanjing City, Jiangsu Province, China. We specialize in the production of a wide range of mechanical blades, including crusher blades, wood chipper blades, shredder blades, and the granulator blades. Our expertise is in customizing and manufacturing the blades to meet customer requirements, utilizing advanced CNC machines grinding machines, heat treatment furnaces, milling machines, lathes and sawing machines.

concrete crushing machine production each blade undergoes meticulous inspection using electronic calipers for verification of dimension precision as per the technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure conformity to high quality standards These tests ensure that our products always meet or exceed customer expectations

Our concrete crushing machine covers over an area of 8 000 square metres and is equipped with top-of-the-line equipment This infrastructure lets us efficiently complete orders with a high degree of precision and high quality We adhere to stringent quality control measures ensuring that raw materials are of the highest grade and that each blade goes through CNC machined to ensure superior precision