Granulator blades – a crucial tool in recycling When it comes to recycling, making material small enough to work with can often be the difference between success and failure. These blades assist in cutting through plastics, rubber, and other materials to turn them into granules, which can be used to create new products. The Huaxin brand is known for Granulator Blades that are super sharp and high quality.

Granulator Bl. ades are the main plant decutting hash knife tool on a good foundation. They used to break large materials into smaller pieces that are easy to process. The recycling of that material would be taking much longer without granulator blades. Bi-metallic guillotine blades from Huaxin are built for speedy and precision cutting applications contributing to efficient recycling.

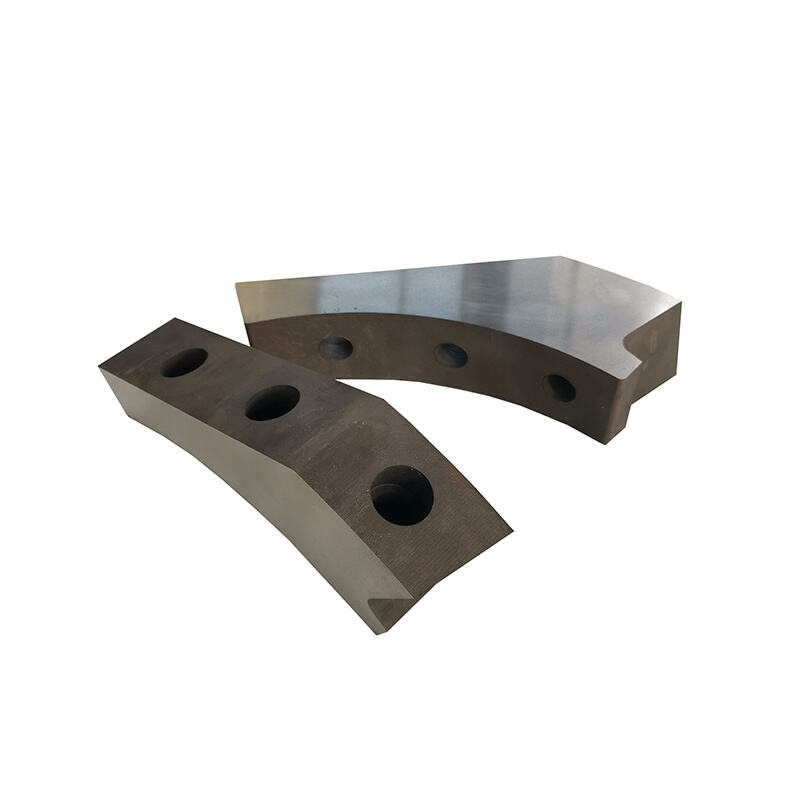

It is ideally designed to make precision cuts by granulator blades. Made of sharp and durable high quality materials, our blades work well on cutting and trimming jobs. Blade of Huaxin granulator is easy to remove for cleaning or to change the variety. This accuracy cut minimizes recycling reprocesses and ensures materials are recycled correctly.

Selecting the correct granulator blades is very important to increase productivity in the recycling process. Huaxin provide various quality standard blades tailored to the particular requirements of various recycling operations. How can a recycling company's productivity be improved?

This Huaxin granulator blade has one of the highest quality cutting edges on the market. Ensure blades are made from durable materials that are able to withstand the abuse of recycling. Huaxin knives are also hand polished to a razor sharp edge and will slice timber cleanly and accurately. When recycling companies need a consistent reliable cutting blade for their facilities, they turn to the blades – and the ongoing service – of Huaxin.

An Overview of Granulator Blades for Recycling Industrial companies have everything to gain from quality granulator blades. These are fast-cutting blades that delivers high-quality results without any delay, thereby promoting faster material-cutting operations. Sharp knives will also cut down on the potential for materials to feed poorly or become stuck during the recycling process less downtime and greater productivity. And because the tough blades are engineered to stay sharp, you can make a ton of cuts without the hassle of constantly replacing blades and save recycling companies time and money.

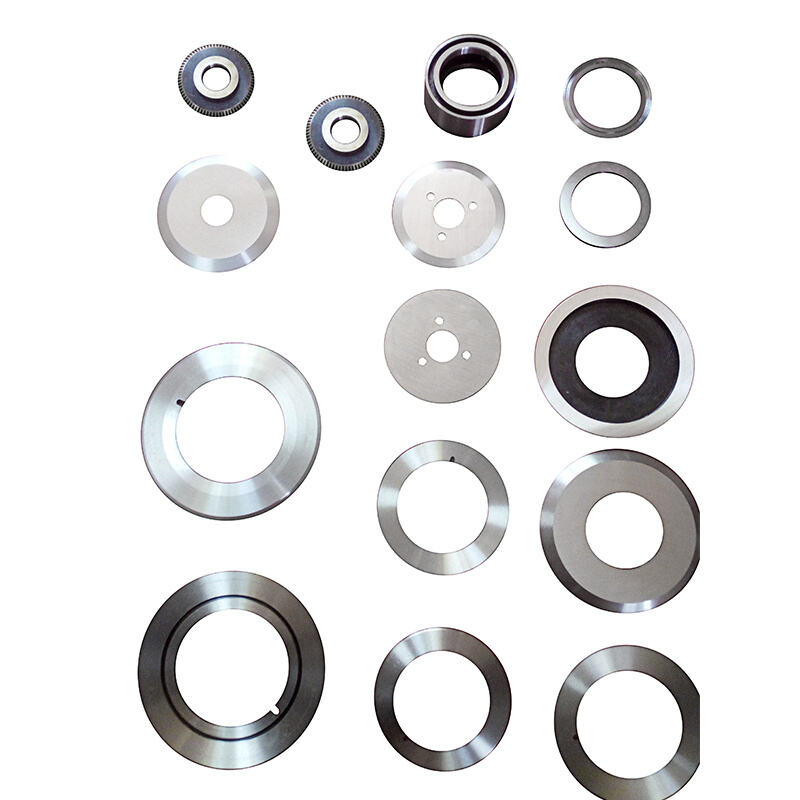

Granulator blade A manufacturer with specialized capabilities, is located in Nanjing City, Jiangsu Province, China. We specialize in making various types of mechanical blades including shredder, crusher and the granulator. We are experts in modifying the blades we manufacture and modifying them according to the particular demands of our clients using advanced CNC equipment as well as heat treatment furnaces.

Granulator blade production each blade undergoes meticulous inspection using electronic calipers for verification of dimension precision as per the technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure conformity to high quality standards These tests ensure that our products always meet or exceed customer expectations

Our manufacturing facility covers more than 10 000 square meters and is Granulator blade with cutting-edge machines This infrastructure gives us the ability to fulfill orders efficiently and with high quality We strictly control quality processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined for maximum precision

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd puts a high priority on quality We employ Granulator blade throughout the production process To enhance durability and performance we use high-quality alloy steels that are specifically designed for tooling applications We also employ advanced techniques for heat treatment using vacuum and deep cooling processes Our dedication to quality can be seen in our products' resistance to abrasion as well as their toughness and long service life putting us at the top of the industry