Are You A fan Of Wood Works? Likely you have either build your own bookshelf, or fashioned a frame from odds and ends of lumber using a saw. Ever used a dado blade before? It might seem like that lame thing only professionals would use, but it can help you tremendously in your woodworking projects. Come take a closer look and find out what some of the benefits are for using a dado blade with your circular saw in woodworking!

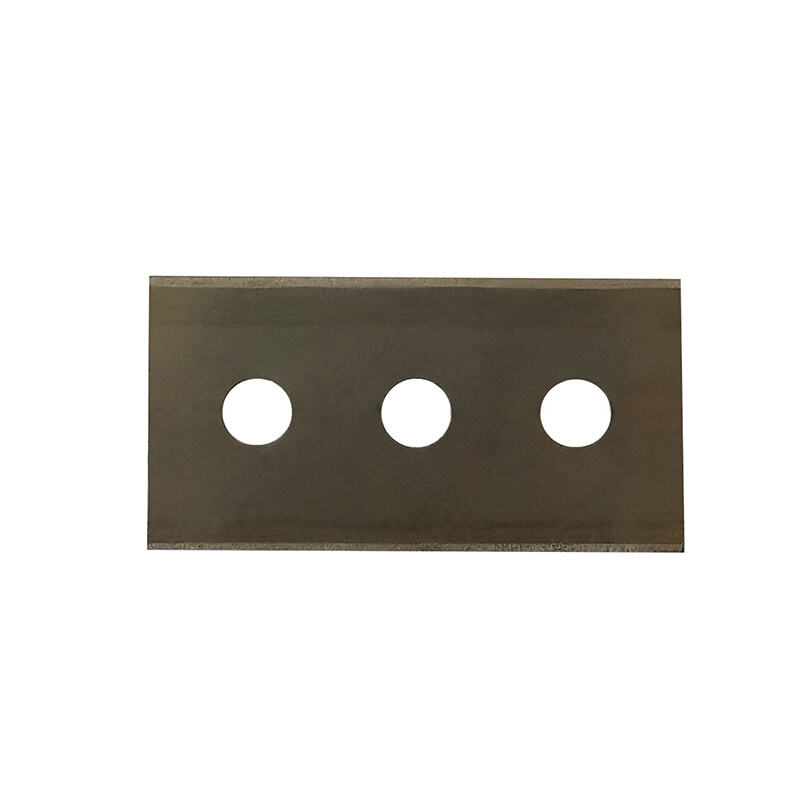

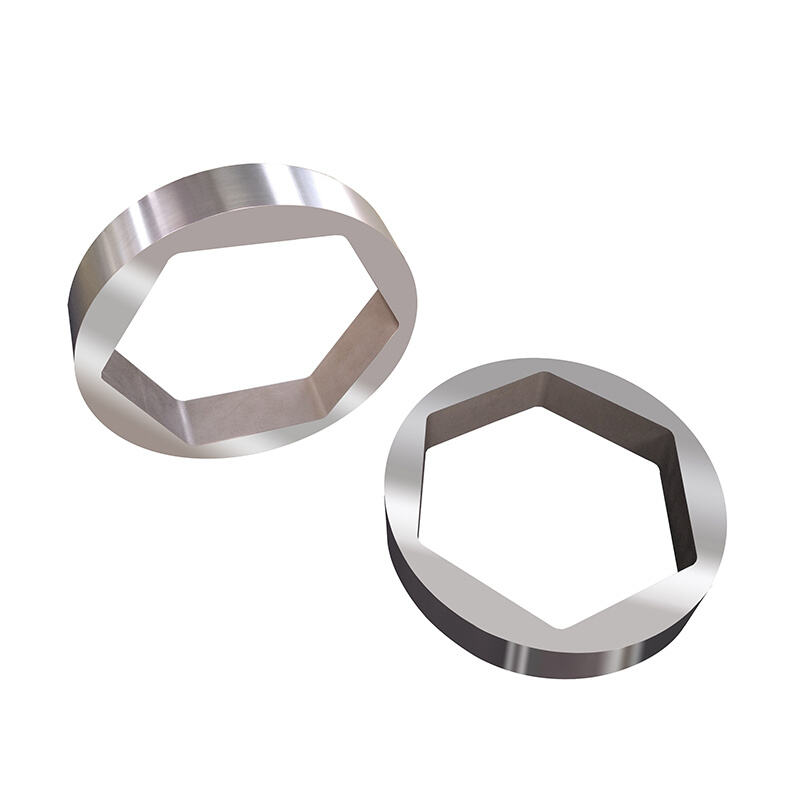

A dado blade by definition is a unique saw blade that differs from the standard and... It has two outer blades on the sides and chippers in the middle. The pattern of the blades that makes it possible for you to create a groove in which we can slot wood is known as dado. You have to make sure you create a dado so that your work is clean and durable. A groove is a long cut along the length of wood that allows other pieces of wood to fit snugly within it holding your completed work together in a sharp, professional light.

There are a lot of benefits when it comes to using dado blades, one in particular is that you can have clean and accurate cuts. For example in this bookshelf you want the shelves to fit exactly into these sides. Thing is it has to have a dado blade so you can cut the correct size groove in the wood without having like 3" shelves which wobble around. The dado blade is smoothing the edges with small blades removes any extraneous pieces of woods from between cuts which also makes smoother accuracy when cutting. Simply put, less time fixing mistakes results in more time enjoying your work when finished!

Plus, you can create custom features with a dado blade Accordingly, you can use it to build spline joints; These are the sturdy corners usually found on picture frames. Having of a good quality Frame Picture Hangers will not only make the frame look better but they also serve to keep it together well. Find out more about how a dado blade can help you in our blog here, which goes into detail on other uses, whether it be cutting grooves for doors or cabinets to add variety and interest to your projects.

Although the dado blade may appear to be intimidating at first, once you understand how it works this is really a simple process. First and foremost, remember that dado blades are sold in a variety of sizes so it is important to choose the right one for your project. If your dimension is off, you will end up with the wrong cuts. You also have to be careful not cut too deep, which can compromise the wood and make your project less durable. Practice makes perfect, take your time and you will be using this great tool like a pro.

Every dado blade for circular saw is carefully inspected using electronic calipers after production to ensure it is in conformity to the technical drawings We conduct test of hardness post-heat treatment to ensure compliance with high quality standards These tests ensure that our products surpass or meet the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialist manufacturer based in Nanjing City, Jiangsu Province, China. We are experts in manufacturing different types of mechanical blades including dado blade for circular saw, crusher and the granulator. We are experts in modifying the blades we manufacture and modifying them to meet the exact requirements of our customers, making use of the latest CNC equipment as well as heat treatment furnaces.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place an emphasis on the quality of its We use rigorous quality control methods throughout the process of production In order to increase durability and effectiveness we utilize high-quality dado blade for circular saw specifically designed for tooling applications We also employ the latest vacuum heat treatments as well as deep cooling techniques We're proud of our commitment to high-quality as evident in the toughness and abrasion resistance of our products and their long service life

Our dado blade for circular saw covers over an area of 8 000 square metres and is equipped with top-of-the-line equipment This infrastructure lets us efficiently complete orders with a high degree of precision and high quality We adhere to stringent quality control measures ensuring that raw materials are of the highest grade and that each blade goes through CNC machined to ensure superior precision