A circular saw blades is a typical cutting tool that many people use to cut thin metals and wood. The saw's power button triggers the round blades into a rotation, spinning at high speeds. The ability to cut so effectively is down in part to a spinning motion that the blades undertake, hence enabling them very sharp and accurate cuts on many different types of materials.

Turbo Circ Saw Blades: Another thing that you need to be aware of when it comes to circular saw blades is the teeth design. There are blades that come with closely located teeth and the other ones contain more spaced out kinds of teeth. Space between the teeth is known as a tooth configuration and it plays an important part in how well the blade functions.

It is a special tooth configuration that can be able to affect many things while cutting. They can play a role in how efficiently the blade will make it through cutting and what its lifespan is. The fewer teeth a blade has, the faster it should cut but you might end up with more of a rough edge on your material. However, a blade with more teeth will make quicker cuts but leave behind less edge accuracy.

There are different kinds of materials you can make saw blades out of, and each material has its own place based on the advantages it offers. Moreover, high-speed steel and carbide-tipped are the two regular types of materials supplied in making saw blades. High-speed steel blades are constructed from a special type of steel that withstands high temperatures very well. They work perfectly for some purposes of cutting.

The edges of carbide-tipped blades, however, are coated with a very thin layer of carbide. This strong stuff is a blessing when you try to slice harder materials like metal or masonry. There are two broad types of blades and they both have different use cases. Fast widia blades are ideal for cutting weaker materials, such as wood, plastic or aluminum; on the other hand carbide tips is most suitable when making cuts in stronger (metal and concrete )

The second thing to think in the material is what kind of cut you want. The kind of cutting shall determine the type of blade to be used. Saw Blades that are designed to cut across the grain of wood such as crosscut blades will leave a clean edge. Ripping blades, however are the type for cutting with and therefore they can take material off fast. There are also combination blades made, which can be used for cross and riser cuts.

Kerf is the width of cut made by saw. A blade blows through the wood, removing a little strip of it that is equal to its kerf and width. The bend in the teeth of the blade is called a hook The hook angle affects how the blade bites into material. Lastly, the grind refers to how the teeth are shaped on it. It comes in 3 forms of grind, Flat (F-L) Alternate( F-ATB), & Triple Chip Grind(TCG). Given how different grinds can cut more quickly and be less smooth edges or just slower cutting but the most perfect of cuts.

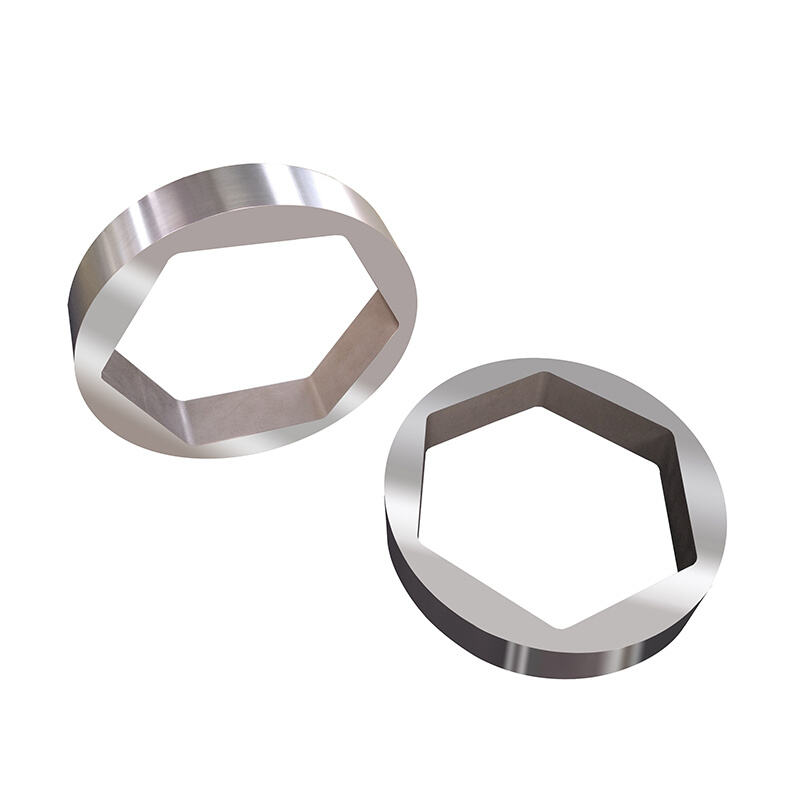

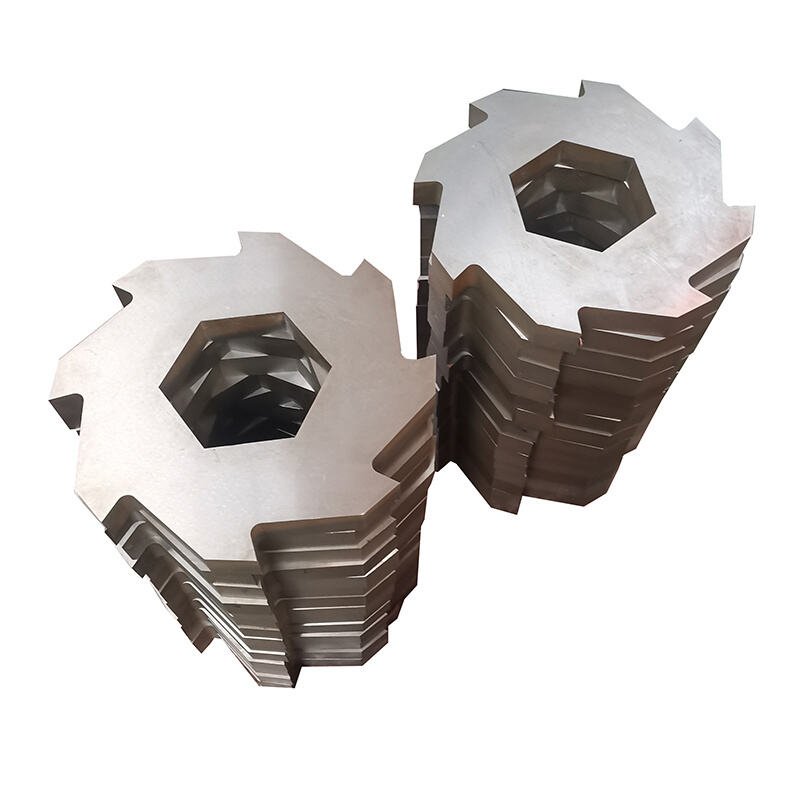

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a types of circular saw blades in Nanjing City, Jiangsu Province, China. We specialize in the production of a wide range of mechanical blades, including crusher blades, wood chipper blades, shredder blades, and the granulator blades. Our expertise is in customizing and manufacturing the blades to meet customer requirements, utilizing advanced CNC machines grinding machines, heat treatment furnaces, milling machines, lathes and sawing machines.

After the production process each blade undergoes meticulous inspection using electronic calipers to verify dimensional accuracy in line with the technical drawings We conduct hardness tests after types of circular saw blades to ensure compliance with strict quality standards These measures ensure that our products exceed the expectations set by our customers

The importance of quality is Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We implement types of circular saw blades quality control measures throughout production In order to increase durability and effectiveness we employ high-quality alloy steels suited to specific application of tools We also use advanced techniques for heat treatment using vacuum and deep cooling processes Our dedication to excellence is evident in our product's abrasion resistance toughness and extended service life putting us at the forefront of our industry

Our manufacturing facility covers more than 10 000 square meters and is types of circular saw blades with cutting-edge machines This infrastructure gives us the ability to fulfill orders efficiently and with high quality We strictly control quality processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined for maximum precision