Are you fond of DIY with timber? If you are, chances are that your cuts need to be exact and clean. So really... thinking about it: you need a finish blade for a circular saw like this one And boy would I love to see how arrogant that silly uncle of mine felt 249.0001 seconds after attempting to use the wrong tool! This tool is the solution for you to make beautiful looks on your wood projects.

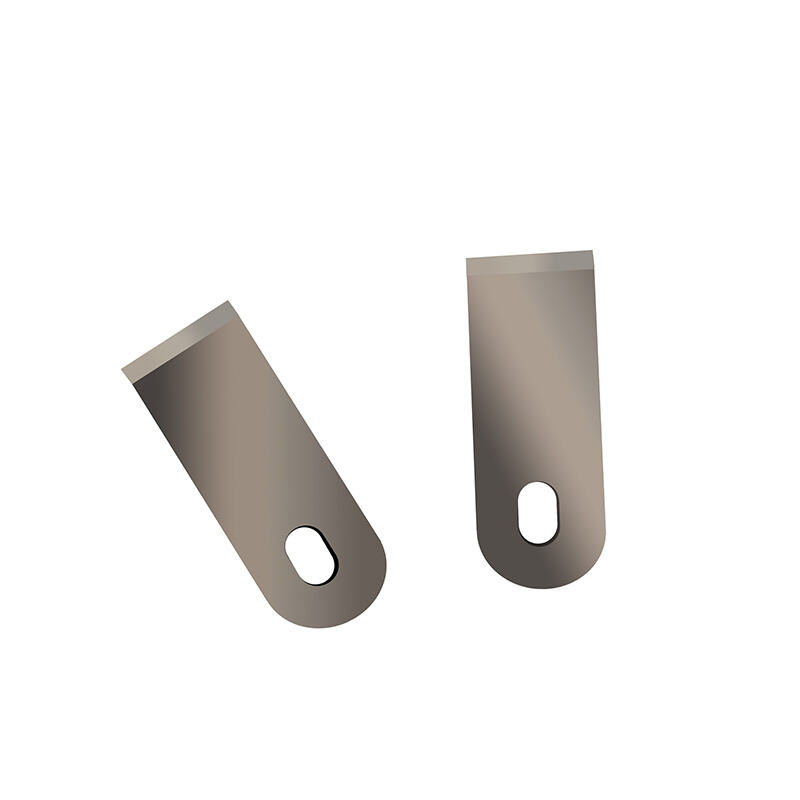

A more specific type of circular saw blade is a fine tooth one, which has teeth that are right next to each other. They are not only smaller, but there is also more of them than the teeth on a standard saw blade. The purpose of this design is to allow the fine tooth blade make as clean cuts. This is essential when working on intricate projects or need to cut thin pieces of wood. It has a fine tooth blade for double edged precision

A fine tooth circular saw blade will provide a more even cut than one made with regular cutting edges. Unfortunately, if you are inexperienced with using a regular blade for your cuts it can be jagged and frustrating to use. Sanding might be necessary in order to clean up the edges of your workpiece which is time-consuming and not exactly easy.

Also, a fine toothed circular saw blade helps avoid any splintering. The process of splintering really mars the surface finish on your project completely. When the blade rips through wood rather than cut it cleanly. So long as you have a circular saw blade that has fine teeth, your cuts will come out smooth and clean thus no splinters. This will help make your projects look professional and neat.

Fine Tooth Ryoba saw blade In addition to this, it will also allow you to polish your woodworking skills. The more accurate your cuts, the older you will be and likewise confidence at an all-time high. This new confidence will see you trying more ambitious designs and taking on bigger projects, come to think of it you might start enjoying your woodworking journey after all.

Many fine tooth circular saw blades types to choose form and its necessary you find the one for your project. One of the most basic considerations is what type of wood you will be cutting. Certain types of blades work good with soft woods whereas the other are meant to be used on harder ones. This information will allow you to choose the appropriate blade.

The last thing remaining is to pick a blade with the correct quantity of teeth. High tooth blades make finer cuts (with more teeth), low tooth count is for rougher cutting of thicker lumbers.This lower pitch blade - what we called a band saws "raker" will be your best bet. The extra time to choose the perfect blade pays off greatly with how your work will look.

Every blade is carefully inspected with electronic calipers following production to ensure it is in conformity to the technical drawings We conduct fine tooth circular saw blade after heat treatment to ensure conformity to strict quality standards This ensures that our products will meet or exceed the expectations of our customers

Our manufacturing facility covers more than an area of 8 000 square metres and is equipped with cutting-edge machines This allows us to efficiently fine tooth circular saw blade orders that require high precision and quality We follow strict quality control procedures making sure that our raw materials are of the highest grade and that every blade is subjected to CNC processing to ensure precision

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a fine tooth circular saw blade with a specialization in Nanjing City, Jiangsu Province, China. We focus on producing an array of mechanical blades. These include crusher blades, wood chipper blades, shredder blades, and the granulator blades. Our expertise is in the customisation and processing of these blades to meet specific demands of the customer, utilizing modern CNC machines grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing equipment.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd places a high priority on quality We use rigorous quality control measures throughout the production process This includes selecting high-quality alloy tool steels that are suitable for the specific tooling applications that utilize sophisticated vacuum heat treatment and deep-cooling methods to increase endurance and performance Our commitment to quality is apparent in our products' resistance to fine tooth circular saw blade as well as their toughness and long service life positioning us at the forefront of our industry