A 12-inch circular saw blade can be a lifesaver when you have several pieces of wood to cut for your projects. A 12-inch round blade saw, of this sort less demanding to experience thicker bits of wood. If you are constructing something for the first time or repairing a broken tool, it is essential to use suitable tools. If you already have a 12-inch blade, your woodworking will be much easier to handle with ease.

A 12-inch circular saw blade has teeth on the outside that help it cut through wood. It has teeth that are specifically shaped to cut though the material very well. These may be made of carbide, steel etc. There are different amounts of teeth on a blade which changes the the cut will look like. A blade with more teeth will produce a finer cut than less number of teeth generally speaking. If you want your project to look clean and professional, this is important info.

Use cutting Plywood – A 12-inch circular saw blade is one of the best tool for plywood. Apply a joint compound ( Spachtelmasse) layer here, as is the case in furniture and many other projects where plywood was used. When you are building, a smooth and straight cut is needed for that helps save time by getting the job done faster.

Shiplap Making - Shiplap is a type of wooden board but it has less maintenance than the other timber products. A 12″ circular saw blade is great for cutting the angled grooves required to build Shiplap walls. This makes your home to stylish which most people are likely to love it.

One of the versatile circular saw blades for work with wood material; which you can enjoy too if you are a lover and prefer to use wood rather anything else such as stone or metal, etc. It will assist in your moving even the toughest of wood and Produce cleaner cuts all around. And with that you will be able to do more complex woodworking projects. Which means you can Speak easy do-it-yourself wood furniture for the home, that way when your done.

You should consider the type of wood which will be cut when you choose a 12-inch circular saw blade. If it is a harder-type wood, you may require more teeth on your blade for an even smoother cut. Of course, if you are cutting softwoods or even plywood a blade with less teeth can still perform well

For a final tip, just ensure to select the right size hole in the center of your blade. This hole is need so we can make on the saw. If the hole size is less then actual blade, then it will not fit properly. However, if it is more significant than that, then you are better off to not use it since this can be dangerous without using limitations therefor; check again before cutting.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place top priority on quality We follow strict quality control procedures throughout the process of production This includes selecting high-quality alloy tool steel that is suitable for the specific applications for tooling using sophisticated circular saw blade 12 inch and deep-cooling methods to increase durability and efficiency We are proud of our commitment to quality which can be seen in the abrasion resistance and toughness of our products as well as their extended duration of service

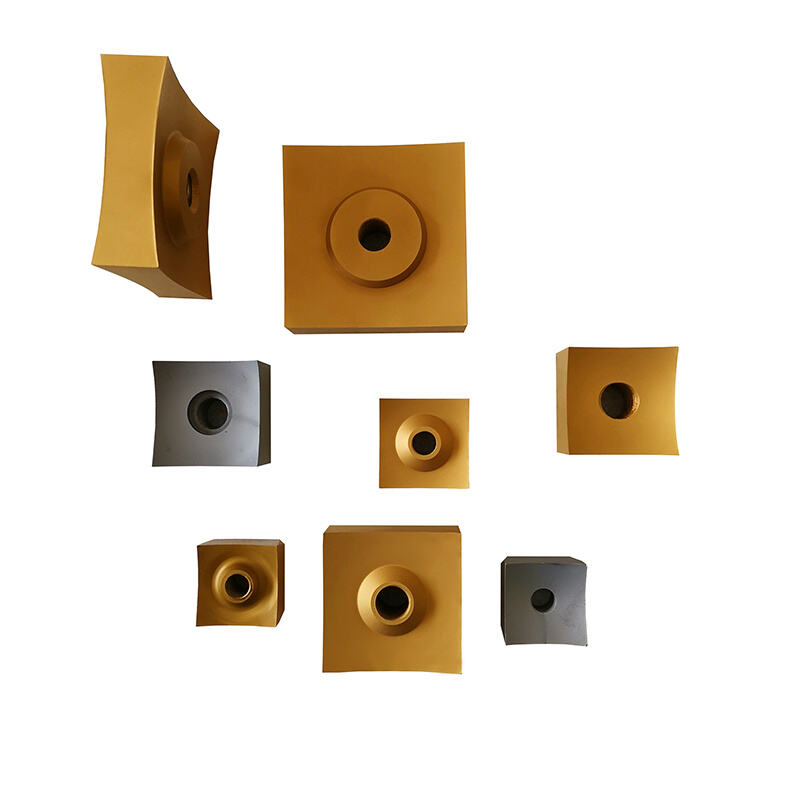

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in circular saw blade 12 inch, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

Our manufacturing facility covers more than an area of 8 000 square metres and is equipped with cutting-edge machines This allows us to efficiently circular saw blade 12 inch orders that require high precision and quality We follow strict quality control procedures making sure that our raw materials are of the highest grade and that every blade is subjected to CNC processing to ensure precision

After the production process each blade undergoes meticulous inspection using electronic calipers to verify dimensional accuracy in line with the technical drawings We conduct hardness tests after circular saw blade 12 inch to ensure compliance with strict quality standards These measures ensure that our products exceed the expectations set by our customers