Introduction of Metal Shear BladesMetal shear blades are strong and tough tools that can be used to reduce metal into a variety associated with designs as well like sizes. They appear in various forms and are a vital tool within the world of building construction, engineering and metal fabrication. In this text, we are going to take a peek at metal shear blades together and will demonstrate why you should use high-quality versions; how to make them provide efficient service for you, save your time as well money with the resource that these types of products offer.

Metal Shear Blades - Metal shear blades are great at cutting metal very quickly and with precision. Expanding the Most Unit About Punches They have been intended to cut sheetmetal cleanly and fast but can perform so without inducing dents from various regions of this alloy. In almost no time, a trained operator can make intricate shapes and patterns with the appropriate blade. It guarantees that the work is top-notch, and it caters to all unique needs of every project. The quality of such blades assures that the output product appears aesthetically pleasing and also works well.

The Benefits of Using Metal Shear Blades Good metal shear blades have several key advantages. To begin with, they are made out of very strong materials that enable them to last much longer than an inferior blade. These springs can take a lot of use without getting worn out. Moreover, these blades are discovered to the accurate cutting and work effectively. Strong materials make the blades reliable, good at their task, and consistent in cutting. It helps save on wastage - by using material judiciously and to its fullest potential, which is of utmost importance.

A metal shear blade choice Determines a perfection in every project What works for one person may not be the best option, and it would depend on factors like their level of experience and what materials they are working with. It is crucial to consider what the project asks for and choose a blade that is appropriate to use. A good blade can facilitate the cutting for you and with less effort,you will get top brass results. So a quality of employee workflow is enhanced.

Metal shear blades are also famed for having reliable solutions that saves time as well money in many situations. This is a positive point on the environment because they allow for less waste as with laser cutting, materials are cut very accurately and there is virtually no scrap left. This becomes beneficial not just for the environment, but more importantly as far project efficiency is concerned. In addition, these blades ensure materials are easy to cut so workers can complete their projects on time or early. This is especially beneficial for businesses that are under strict deadlines and want to get work done fastest while maintaining optimal quality. Not only are you able to save in the long run with less waste and more efficiency, but also help your production costs go down using good metal shear blades.

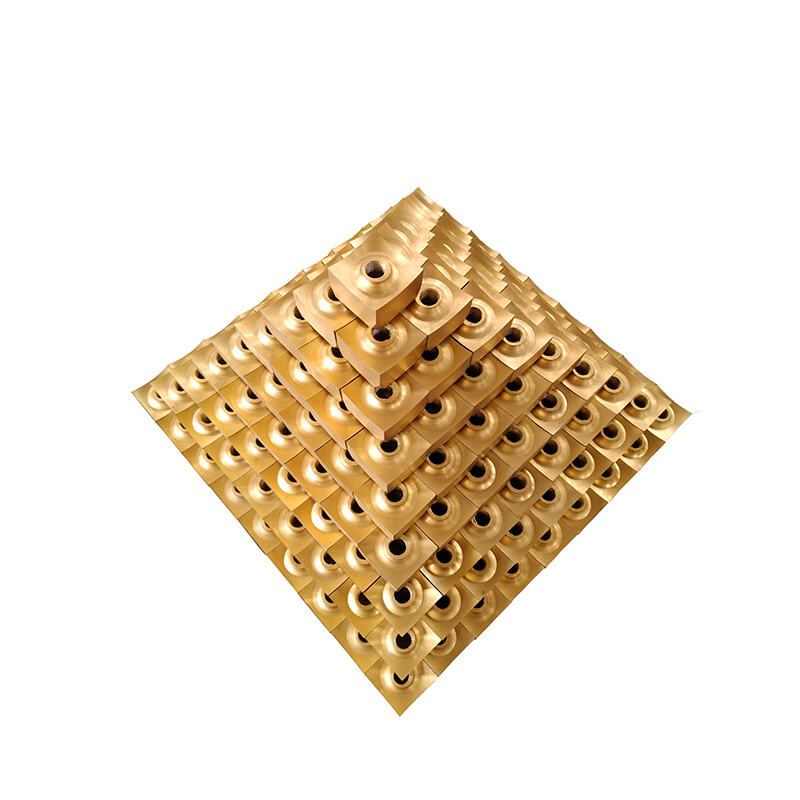

So, what metal shear blades actually are? These are high carbon steel tools, intended to be used for cutting through metal materials. They are sharp blades with cutting edges which will cut through sheet metals cleanly and accurately. The cutting process of several factors that play an important link with the success or failure such as blade angle, cutting speed and tool design. Choosing the right blade for a particular job is very important, because using it incorrectly can cause damage to the blade and worst injuries.

Each blade is rigorously examined using metal shear blades at the time of production to ensure it is in conformity to technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure compliance with high quality standards These tests ensure that our products meet or exceed the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialized manufacturer located in Nanjing City, Jiangsu Province, China. We specialize in producing various mechanical blades like shredder, crusher and the metal shear blades. We are experts in modifying the blades we manufacture and modifying them in accordance with the particular demands of our clients making use of the latest CNC machines and heating furnaces for heat treatment.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place top priority on quality We follow strict quality control procedures throughout the process of production This includes selecting high-quality alloy tool steel that is suitable for the specific applications for tooling using sophisticated metal shear blades and deep-cooling methods to increase durability and efficiency We are proud of our commitment to quality which can be seen in the abrasion resistance and toughness of our products as well as their extended duration of service

Our factory metal shear blades over 8000 square meters and is equipped with the latest machinery This facility allows us to effectively fulfill orders with high precision and quality We adhere to strict quality control processes to make sure that the raw materials we use are of high quality and that each blade is CNC-machined to achieve maximum precision