Plastic is everywhere! Things like our food packages, toys and even for the phones we use. This is a highly crucial commodity in our life. But who of us thinks about the fate of plastic waste after we drop it into a bin? Unfortunately, much of this plastic is left behind in mega trash piles (landfills) or even out in nature due to littering. Environmental Misbehavior is not wanted But there is good news! By a machine other than an ordinary paper shredder or document destruction/shredding company to be sure that the material can indeed be recycled safely (plastic crusher is such special equipment).

These machines literally shred plastic into tiny particles. It is like one big mixing machine ( blender) that slashes plastic in smaller pieces! Once the plastic has been shredded, it can be melted down and reused for other products. So, instead of disposing plastic after a single use, we can recycle it and reuse. This helps lower waste and save resources that we need for other things

The plastic crushing machine is an intelligent and green recycling machinery of viseo_network. Reduces plastic waste into landfills and oceans. Health and the Environment Our rubbish can harm animals or even make our Earth sick. Sea turtles (jellyfish eaters that are also pooped out by the Portuguese man o' war with munched stingers in them) presumably mistake plastic bags for jelly fish and suffer horribly in consequence, to give one example. Recycling plastic also saves natural resources like oil, which is required to make new plastics.

Moreover, these machines consume far less energy in recycling plastic than would be needed to produce new plastic from feedstock. Try to imagine how much work it takes — first dredging for oil, then manufacturing plastic and finally all the things fabricated from plastic! One way I think we could reduce our pollution and use less energy is by crushing with a machine. Which shows we are collectively being a little kinder to our planet.

Staying Recycling of Plastic helps in using resources efficiently and waste reduction. We could find a way to use items made from plastic over and over instead of just once before throwing them away. For instance, when it comes to something like water bottles that get used once and are then thrown in the garbage. When we recycle these bottles and use them again, then we are simply helping to ensure that our planet stays clean and healthy.

This in addition to a culture of recycling plastics so that products are reused and recycled rather than disposed. In turn, it makes our reliance on finite resources such as oil less and heads us in improving efficiency of a greener society. Picture a world in which nothing is ever wasted and every resource that can be used, is. It is the future we achieve through plastic crushing machines.

Plastic waste is a significant issue on our planet. Annually, more than 8 million tons of plastic end up in our oceans. This plastic trash can harm marine life and degree the fitness of our planet. Fish and birds can become ensnared in plastic, while other animals may perceive it as prey despite the dire consequences of eating so. A plastic crushing machine, however, provides the answer to how we can deal with plastic waste.

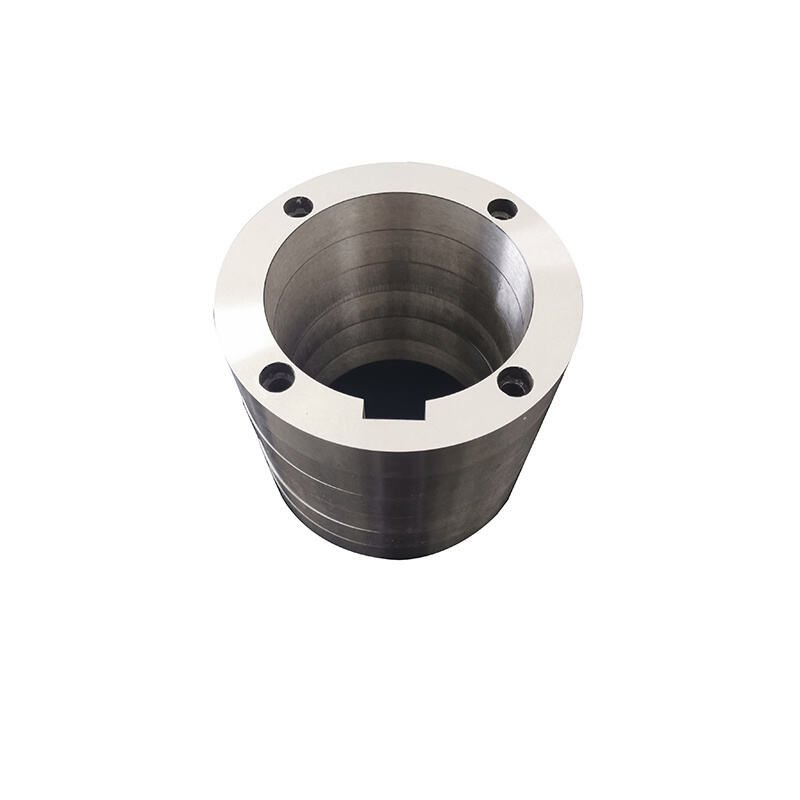

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in plastic crushing machine, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd It places the highest importance on quality We use rigorous quality control methods throughout the process of production This includes choosing the highest-quality alloy tool steel that is suitable for the specific tooling applications that utilize advanced vacuum heat treatment and plastic crushing machine to increase durability and performance We are proud of our dedication to high-quality products which is evident in the toughness and abrasion resistance of our products as well as their extended duration of service

Our manufacturing facility covers more than 10 000 square meters and is plastic crushing machine with cutting-edge machines This infrastructure gives us the ability to fulfill orders efficiently and with high quality We strictly control quality processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined for maximum precision

Each blade is thoroughly inspected using electronic calipers after production to ensure that it conforms to plastic crushing machine We conduct hardness tests after heat treatment to ensure compliance with stringent quality standards This ensures that our products satisfy or exceed expectations of customers