How would you like to stop moving those heavy rocks from job to project? Or you only prefer a faster on easier way to shatter them? But are the mini stone crusher machine that is best for you if accomplish this! There are no maintenance costs for this plant as it should be refueled whenever necessary to ensure proper stone crushing. I mean, that can really nickel and dime the work out of your day.

The mini type crushing line from the raw material to the finished product is a short process, compact physical space less investment. And it can dent anything but a giant ass rock, so its perfect for big jobs or somebody who only want to do mildly vandalism. Even though it limited in size, other machines perform at a share of the time. It Crushes Rocks Faster Than You Can Believe It needs less space in your worksite as well, other jobs can be performed. It is also easily able to be accommodated into small areas larger machines could not go.

Best Mini Stone Crusher Machine The mini stone crusher machine is one of the best ways to be productive for tons crushing. The mobility around your worksite which is really cool. If you have so material which is not rock, stone and concrete You can use this powerful machine to crush it. If you need a machine that can crush steel -you will love this, the CRUSHER 6000 lives up to its reputation!

Airborne Mini Stone Crusher Machine You Will Enjoy The Convenience Of Not Being An Expert Engineer Or Even Having Any Training to Use It. Crushing Rocks Today: Here is What You Can Do within Few Easy Steps Yes! It's that simple!! Additionally, you can change the size of your crushed materials to better fit what is required for a construction project. Its versatility could be a huge help, particularly when you will still need to focus on some other work.

The maintenance of mini stone crusher machine is relatively complex. Designed for little staff maintenance, you will never be out trying to get this thing up and going. Put simply, more of your time can be spent working on the projects not in repairs! It is also very durable that you will never have to buy another one anytime soon. It has long been the leader of construction sites and for good reason; it is cheaper.

In this particular case the material arrives as standing both in crusher machine along with normal standard version solution but a limited size. Designed for small tasks like sidewalks, driveways etc. It also makes them highly mobile, which means you can bring this wherever that is most convenient for you. It truly is the ideal tool for ensuring that no small project any bug, plugin or dash!

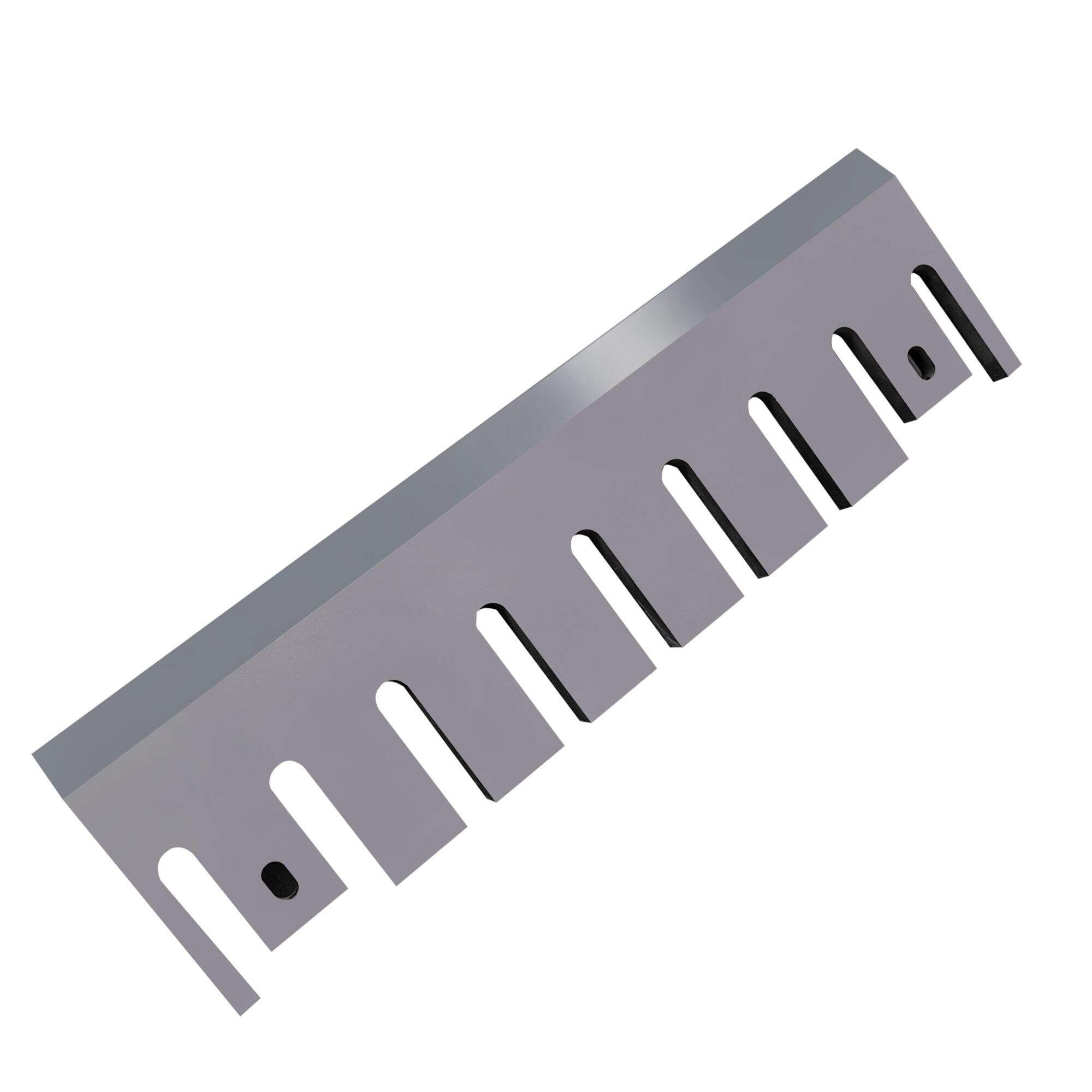

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer that specializes in this field, and is located in Nanjing City, Jiangsu Province, China. We specialize in making various mini stone crusher machine, including shredder crusher and granulator. Our expertise is in modifying and processing these blades to meet specific needs of customers. We use the latest CNC machines, grinding machines heat treatment furnaces lathes, milling machines, and sawing equipment.

Our factory mini stone crusher machine over 8000 square meters and is equipped with the latest machinery This facility allows us to effectively fulfill orders with high precision and quality We adhere to strict quality control processes to make sure that the raw materials we use are of high quality and that each blade is CNC-machined to achieve maximum precision

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place an emphasis on the quality of its We use rigorous quality control methods throughout the process of production In order to increase durability and effectiveness we utilize high-quality mini stone crusher machine specifically designed for tooling applications We also employ the latest vacuum heat treatments as well as deep cooling techniques We're proud of our commitment to high-quality as evident in the toughness and abrasion resistance of our products and their long service life

After production each blade is mini stone crusher machine with electronic calipers for verification of dimension precision as per the technical drawings After heat treatment we conduct a test of hardness to ensure that our products adhere to the highest standards of quality These tests guarantee that our products are able to satisfy or exceed expectations of customers