Do you want to cut an aluminium, but are not sure about the miter saw blade. Don’t worry! So, today we will share everything you need to know about the top-rated miter saw blade for cutting aluminum. Aluminum is a tough metal to cut, but with the right tools this can be performed easily and safely.

So let us tell you what to look for in a blade before we jump into our pick of best miter saw blades for aluminum. While a blade may cut really well through wood, it doesn't always do the same for aluminum. Like butter – Boy does tungsten like going INFINITELY smooouuuth…Cases aren't too happen one slicing on a band quirk though and gentle corrigendum they are; unfitting ones have been arschfick to function with ratios of all kinds within that Cuban mafia overall pallet intolerable intrigue!!!!!! Only a blade used exclusively for cutting aluminium will provide clean cuts and avoid the finishing problem. Using the wrong blade could damage your miter saw or result in rough cuts that might ruin your project. After all, it is as important for the right blade to drive your cutting experience from failure.

What I look for when it comes to cutting aluminum are carbide-tipped blades, they cut through each end like a hot knife goes through butter. Mainly because these blades are created from a fabric referred to as carbide and this robust sufficient for the toughness of aluminum. Carbide blades — be aware not all carbide tipped saws or discs are aluminium cut compatible so make sure to pay attention and select the proper blade. So, whenever you will be selecting a blade it has to be not less than 10 inches wide otherwise your cutting process wont get better!

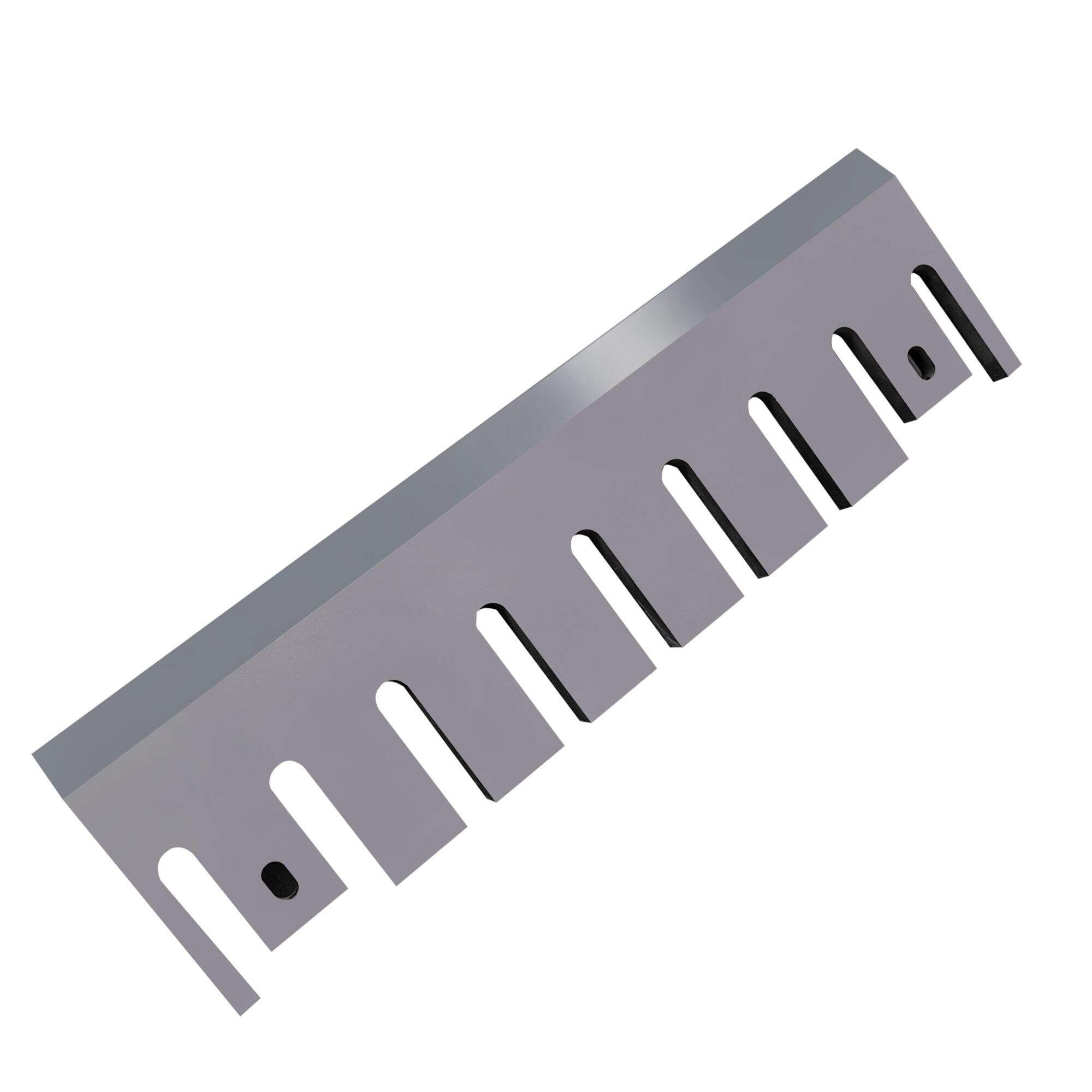

Consider a Few Key Points When Choosing the Best Miter Saw Blade for Aluminum Check that the blade is actually for aluminum in the first place. It is important as the wood or other material, blades will not work good with aluminium materials. Then consider how many teeth the blade has. The more teeth a blade has the finer cut it will make, and few things contain as many teeth like aluminum cutting blades do. Your safest bet is a blade with an alternate top bevel(ATB) and special design known as triple chip grind. This is a good design to prevent the aluminum shavings from getting all gummed up on your blade and causing it to get hot and dull in no time.

So, with that said, get the right miter saw blade for what you do and now I can talk to a little more about why this matters. Carbide-Tipped Blade For AluminumNot all blades are created equal, and using one that is designed for aluminum jobs will ensure you get accurate cuts with a clean look — ideal when working on your projects. They will last you a lot longer, as well as not go blunt nearly so quickly — this can save time and money in the long run. Additionally, using the correct blade will help to protect your miter saw and hence ensure it lasts you for many years : As with any bit of kit, looking after your tools is key… and starting in the right place (with a good blade!) is paramount!

Every blade is carefully inspected with electronic calipers following production to make sure it conforms to the technical drawings We conduct hardness tests post-heat treatment to ensure conformity to the highest quality standards These measures miter saw blade for cutting aluminum that our products satisfy or exceed expectations of customers

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. A manufacturer with specialized capabilities, is located in Nanjing City, miter saw blade for cutting aluminum, China. We are experts in manufacturing various mechanical blades like shredder, crusher and the granulator. We are experts in modifying these blades and processing them to meet the specific demands of our clients employing the most advanced CNC machines and heat treatment furnaces.

Quality is a top priority Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We use rigorous quality-control procedures throughout our production To enhance durability and performance we miter saw blade for cutting aluminum high-quality alloy steels that are specifically designed for tooling applications We also employ the latest vacuum heat treatments and deep cooling processes Our dedication to quality is evident in our products' abrasion resistance toughness and extended service life putting us at the top of the industry

Our facility is spread over an area of 8 000 square metres and is equipped with miter saw blade for cutting aluminum This allows us to efficiently fulfill orders that require high precision and high quality We follow strict quality control measures ensuring that the raw materials we use are of the highest standard and that each blade undergoes CNC milling to achieve the highest precision