Steel circular saw blade is essentially a very sharp machine which allows it to cut through rigid materials such as wood, plastic and metal. The demand for this product is high due to their durability and lifespan in application ranging professionals handling instruments on a daily basis, all the way down to DIY fans who simply like fixing things from my abode. From this text you will discover lots of advantages concerning steel circular saw blades, ways to pick the right one based upon your job and how it is possible to help make sure that they function properly for an extended time.

Steel Blades — All steel circular saw blades are built to use heavy-duty, high grade materials so they can lastEticaret Paket Hesaplama Its blade has a special transverse-teeth teeth configuration that makes it cut nicely. So when you actually use the blade, it gives a smooth and clean finish to your cutting material. A circular saw blade can cut through hard things such as concrete and metal much easier than other saws. Having a blade with this round shape helps it deliver more precise and accurate cuts than other saws, something that is crucial when working on projects requiring fine-tuned measurements.

A steel circular saw blade requires utmost attention in order to do the work well and properly. Step 1: Determine what you are going to cut Different types of saw blades work best for different materials, so make sure you have the right blade before starting a job. There are specialised blades available for wood, metal and plastic for instance. The size and thickness of the blade is something you also need to examine. You can usually use a thin blade aimed mostly to soft materials like wood and thicker for hard going materials as metal. You also need to ensure that your blade is the right size for the band saw you plan on using it — if not, there could be a risk of injury and wear from continued use.

Steel Circular Saw Blades: Steel circular saw blades are designed for cutting metals and concrete materials. But, you must have the right blade and know how to cut properly so as to successfully slice these sturdy things. Be sure that annular cutter teeth are running the Correct way when cutting through Metal. You may also want to go slow as you cut (otherwise the blade can heat up and wear out quickly) When cutting concrete, a diamond-tipped blade and water are usually the best choice; keep that thing wet when you're slicing concrete or else risk overheating it (and ruining the damn...)

If you take care of your steel circular saw blades, they will remain in good shape and last longer. Another use a different knife, you can not just throw away the other blade that easily and also remember to clean your blades after being used so that it does not get rusted. Once the blades are in place, make sure to wipe down or brush any dirt and debris from around them. So too is maintaining the blade; regularly sharpening it. A sharp blade can help to make more even cuts, and also just be safer. You can either file the blade yourself, or you will need to take it somewhere that offers professional sharpening services.

A steel circular saw blade can be considered as an important tool to have for those who practice in projects, they may work on a professional one or just do some DIY at their home. This is a pretty versatile tool since it can make easy work of many different materials and cut through them in no time, so you might as well have one. A circular saw blade has been uniquely designed to slice through stuff in a way unlike any other type of saw, which is why you see so many people choosing this as their weapon of choice for various projects and tasks – both craftsmen and DIY fans!

Our steel circular saw blade covers over an area of 8 000 square metres and is equipped with top-of-the-line equipment This infrastructure lets us efficiently complete orders with a high degree of precision and high quality We adhere to stringent quality control measures ensuring that raw materials are of the highest grade and that each blade goes through CNC machined to ensure superior precision

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd puts top priority on quality We employ stringent quality control methods throughout the process of production In order to increase durability and steel circular saw blade We use premium alloy steels designed specifically for tooling applications We also employ the latest vacuum heat treatment and deep cooling techniques We're proud of our dedication to quality which is evident in the toughness and abrasion resistance of our products as well as their extended time of service

After the production process each blade undergoes meticulous inspection using electronic calipers to verify dimensional accuracy in line with the technical drawings We conduct hardness tests after steel circular saw blade to ensure compliance with strict quality standards These measures ensure that our products exceed the expectations set by our customers

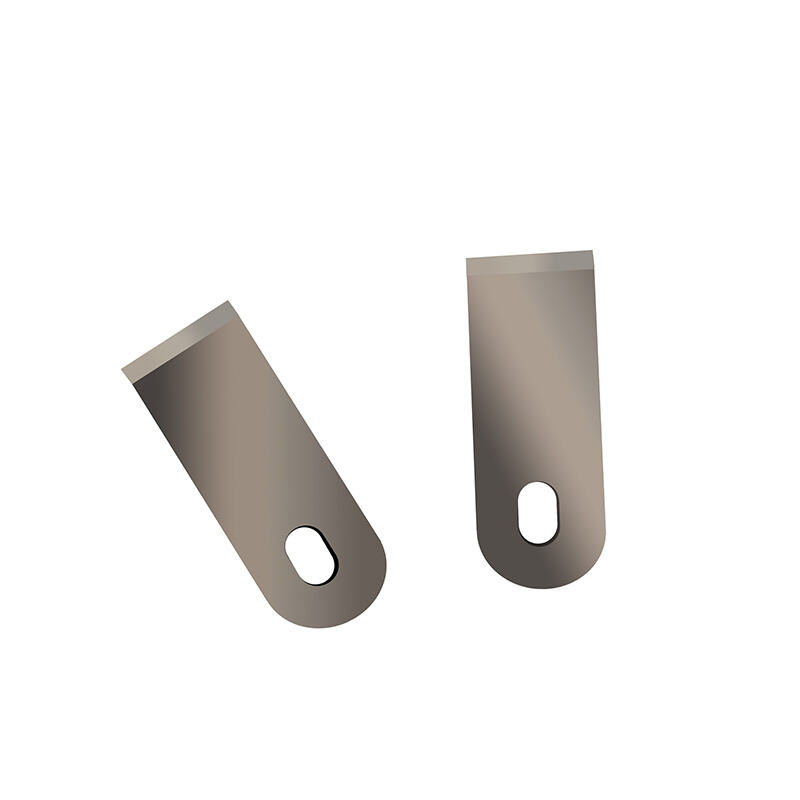

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a specialization in Nanjing City, Jiangsu Province, steel circular saw blade. We specialize in producing various mechanical blades, including shredder crusher, and granulator. We specialize in customizing these blades and processing them to meet the specific requirements of our customers, by using the most modern CNC equipment as well as heat treatment furnaces.