But have you ever used a saw to cut wood, or anything else? If you have, then chances are good that you know how crucial a saw blade can be This power tool is a special type of saw blade and designed for people in order to assist them make clean precise cuts using fine tooth skill saw blades. A critical workbench for planning where accurateness is needed in your additional facility.

Fine tooth skill saw blade is another type that you can use to cut different materials more smoothly and precise. And you can always come back to clean it up and have zero jagged or rough edges left. Having square, clean edges are really essential for the sake of getting precise cuts you need to keep your project together. Like getting everything to slide together perfectly with no gaps if you were making furniture/grain faces/upholster/etc. With the help of a fine tooth blade you can ensure that your cuts are on point.

A fine tooth skill saw blade has a lot of great advantages. One of those benefits is a blade that allows you to make cleaner, smoother cuts. This is incredibly useful in a scenario, where you are working on a very strict project. For example, if you are creating something that needs to appear pretty like a shelf or picture frame then it would be good for those cuts tpo be tidy. This has another amazing pro that it saves your time and energy. It allows the blade to pass through quickly and effortlessly, so you are left with no rough edges on which more time has to spent sanding or correcting. This saves you struggling with how to make those cuts look great and lets you concentrate on other elements of your project.

In case you are cutting very accurately then this thing makes the fine tooth skill saw blade a must use for that specific project. This helps you bring about the smoother cuts to avoid any jagged edges. It is extra useful in case you have a cut-off date to fulfill. A toothed blade through which you can quickly cut any material, without loosing much time. This will also save energy since you don't have to come back and less about things later on. Efficiency is one of the keys that allow you to get things done on a certain project by some deadline.

Each task should have a specific task example where you can utilise fine tooth skill saw blade in your case. Fine Tooth Saw Blade Sizes and Material The blade size needed for your saw will depend on the size of the power tool itself. A smaller blade is required because your saw is small. If on the other hand, your saw is some-what larger well then you'll need a bigger blade. The material with which a blade is constructed will vary depending on what it is you are attempting to cut. Example: if you were slicing some wood, you would need a blade specifically made for cutting through THAT wood. This is so you can achieve the perfect cut every time.

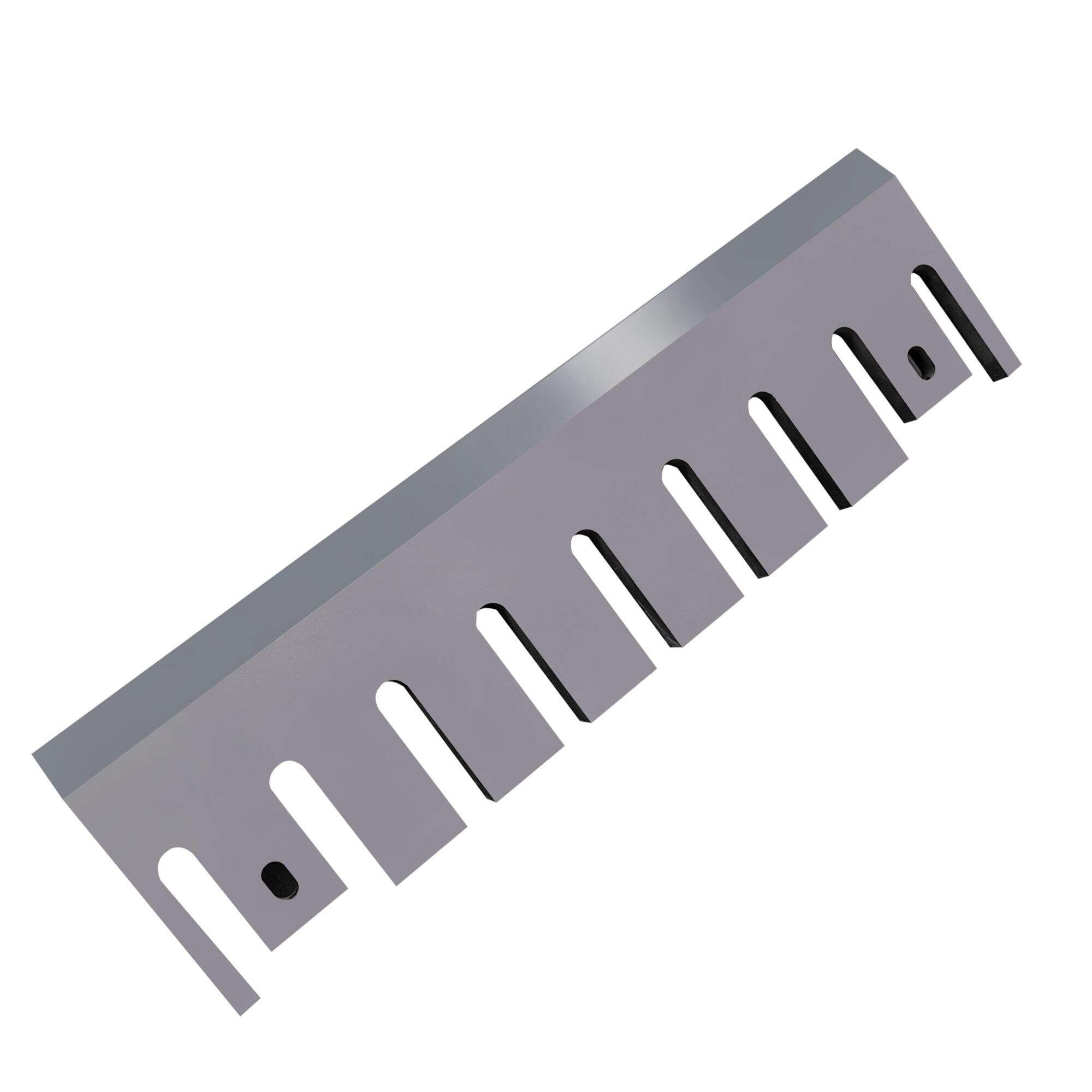

Our manufacturing facility covers more than 10 000 square meters and is fine tooth skill saw blade with cutting-edge machines This infrastructure gives us the ability to fulfill orders efficiently and with high quality We strictly control quality processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined for maximum precision

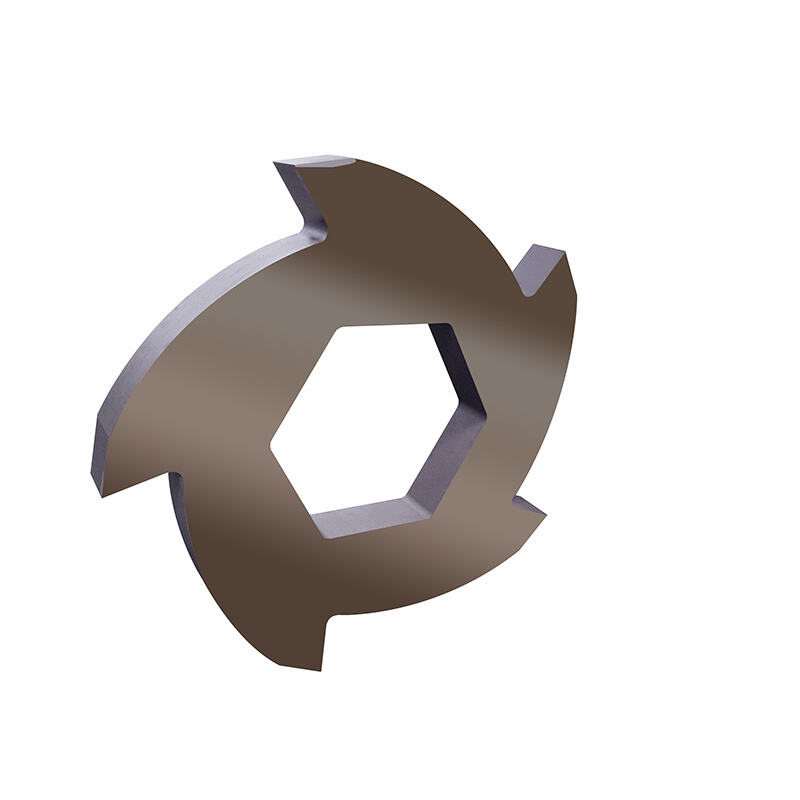

fine tooth skill saw blade A manufacturer with specialized capabilities, is located in Nanjing City, Jiangsu Province, China. We specialize in making various types of mechanical blades including shredder, crusher and the granulator. We are experts in modifying the blades we manufacture and modifying them according to the particular demands of our clients using advanced CNC equipment as well as heat treatment furnaces.

Each blade is rigorously examined using fine tooth skill saw blade at the time of production to ensure it is in conformity to technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure compliance with high quality standards These tests ensure that our products meet or exceed the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd places a high priority on quality We use rigorous quality control measures throughout the production process This includes selecting high-quality alloy tool steels that are suitable for the specific tooling applications that utilize sophisticated vacuum heat treatment and deep-cooling methods to increase endurance and performance Our commitment to quality is apparent in our products' resistance to fine tooth skill saw blade as well as their toughness and long service life positioning us at the forefront of our industry