Now, cutting tiles is very difficult however when you use a tile blade for your circular saw. A tile blade is a disc that fits onto most circular saws. Best tile cutter blade are created for cutting tiles (tiles) in order to reduce on soft porcelain and ceramic floor coverings easily.

Ceramic tiles themselves are very strong and durable, which is actually a problem because it makes them difficult to cut. But when a tile blade comes into action, you can easily cut these ceramic tiles. the special blade of this one cut ceramic tile very easily which was like slicing a soft butter with warm knife. And, God(!) it works so well!

If you are chopping the tiles, then keep in mind that a raft of water is going to be required for this purpose. I share for a few different reasons that I will dive into in an upcoming post.icient. One, it aids in keeping the blade cool when under use which is essential to prevent overheating of the blades. Second, the water will help cut down on the amount of dust created when cutting. Not only does it work wonders on your health, but it also keeps havoc out of the office. And finally, by using water you prevent the blade from getting ruined because it is not good if a tile saw heats too much of dust amasses.

Finally, tiles are difficult to cut through although a very good quality tile blade can take care of this with ease. With this blade, you can cut the tiles that put fear in your heart. It we the work done much easier and far less painful, you can concentrate on your project then concentrating how to get your job doe.

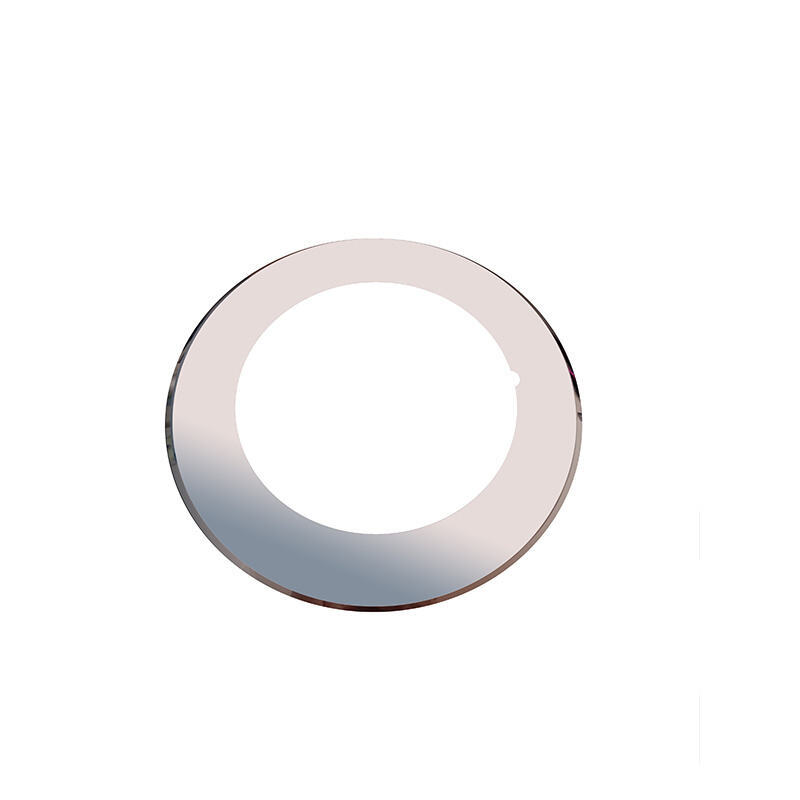

An used on the circular saw with this tile blade (depending) This blade will fit on your saw like a standard bade would. It is imperative to get the blade that corresponds with your saw so make sure you purchase the appropriate size for yours. Different sizes may cause problems — or worse, accidents.

With proper installation of the blade onto your saw, you are now ready to cut tiles. Be sure to work with a lot of water and do it slowly. There is a lot of detail to cutting tiles, and you need it done right. Haste makes waste, hurrying through the job only results in mistakes and errors that can cause damage to your tiles.

But, cutting tiles is something you have to be cautious about. Just be careful as they are a bit fragile and the last thing you want is to break them or use material in vain So, slow down and add some water; be patient. Cutting tiles is quite a difficult task but with an appropriate tile blade, it becomes so much easier.

Quality is a tile blade for circular saw at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We implement rigorous quality control procedures throughout the production To enhance durability and performance We use premium alloy steels specifically designed for tooling applications We also employ the latest techniques for heat treatment using vacuum and deep cooling techniques Our commitment to quality is apparent in our product's abrasion resistance toughness and extended time of service which puts us at the top of our industry

Every blade is carefully inspected with electronic calipers following production to make sure it conforms to the technical drawings We conduct hardness tests post-heat treatment to ensure conformity to the highest quality standards These measures tile blade for circular saw that our products satisfy or exceed expectations of customers

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd., a specialized manufacturer, is located in Nanjing City, Jiangsu Province, China. We are focused on the manufacture of a wide range of mechanical blades, such as tile blade for circular saw, wood chipper blades, shredder blades and the granulator blades. Our expertise lies in customizing and manufacturing the blades to meet needs of our customers, using advanced CNC machines, grinding machines and heat treatment furnaces. milling machines, lathes and sawing machines.

Our manufacturing facility covers more than an area of 8 000 square metres and is equipped with cutting-edge machines This allows us to efficiently tile blade for circular saw orders that require high precision and quality We follow strict quality control procedures making sure that our raw materials are of the highest grade and that every blade is subjected to CNC processing to ensure precision