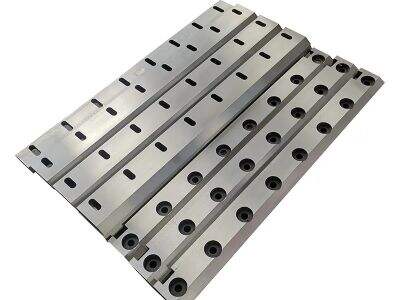

A lot of people really struggle with materials selection when they're making blades for plastic crushers. To say nothing of the earthly need for blades that are strong, tough and last a while. At Huaxin, we are committed to high quality and the use of the best materials in our plastic crusher knives so that our products will be the most reliable and lasting. So let’s take a look at the type of materials that make these blades work the best

Selecting the Appropriate Steel for Your Durable Plastic Crusher Blades

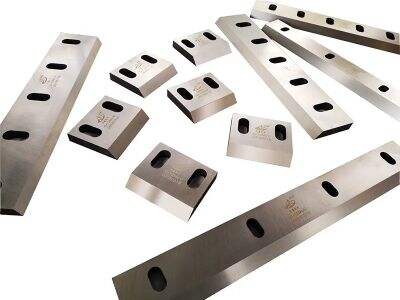

Plastic crusher blade is made of special steel, high hardness, high wear resistance. “I would use high-carbon steel because it’s really hard and you can keep a very sharp edge on it. However, it can be brittle. In contrast, stainless steel doesn’t rust, a great quality for knives that are prone to get wet. Here at Huaxin, we employ an assortment of steels to ensure our blades are strong and efficient

The Significance of Hardness and Toughness of the Material of Plastic Crusher Blades

A knife must be hard to slice easily through the plastic. But if it’s too hard, perhaps it will break easily. That’s why toughness, is a key consideration too. Strength is simple : The blade has to be able to take a really hard whack and not slip off the mandrel. Key to good plastic crusher blade is the balance between the hardness and the toughness. It is this balance that we strive to achieve in each of our knives at Huaxin

Heat-Treated Plastic Crusher Blades For Maximizing Performance

Heat treatment — a heating and cooling process to alter metal’s molecular structure to impart strength and flexibility improves it for specialized uses. The blades of plastic crusher can be treated with heat to cause them to become harder so as to increase their durability and to be more resistant to wear and tear. That’s because they last longer and perform better. At Huaxin we have honed our process to include the best quality raw materials, exceptional forging, the ideal in heat treatment and a rigorous final grind

Find out about the advantages of carbide tipped blades for plastic crushing applications

Carbide-tipped blades are another option. Carbide is hard as all heck and just stays sharp longer than plain steel. These blades can cut through more aggressive plastics and last longer before replacement is necessary. They may cost more initially, after all, but could be less expensive in the long run, as they don’t have to be thrown away as frequently. We are at huaxin believe that it is our obligation to offer carbide-tipped blade according to the different requirements

The Effect of Material Selection on the Longevity of Plastic Crusher Blades

Material selection for the plastic crusher blades don’t come down to performance only. It also determines how long the blades will survive. Higher-quality materials may be more expensive, but they’ll pay off in the long run when you won’t have to replace the blades as frequently. At Huaxin we think a lot about longevity, and we like to make sure our blades are a good investment for our customers

By choosing the best raw material and process, Huaxin makes sure our plastic crusher blades not only have better cutting performance but also have a longer service life compared to others. Our blades can accommodate both soft and hard plastics

Table of Contents

- Selecting the Appropriate Steel for Your Durable Plastic Crusher Blades

- The Significance of Hardness and Toughness of the Material of Plastic Crusher Blades

- Heat-Treated Plastic Crusher Blades For Maximizing Performance

- Find out about the advantages of carbide tipped blades for plastic crushing applications

- The Effect of Material Selection on the Longevity of Plastic Crusher Blades

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV SR

SR SK

SK VI

VI MT

MT TH

TH TR

TR FA

FA AF

AF GA

GA CY

CY LO

LO LA

LA NE

NE SO

SO MY

MY KK

KK