Plastic recovery machine blades are very important in plastic recycling field as they are used to crush big plastic items into milling size. The life of those blades may have many factors, from the material quality to the maintenance it receives. As a professional manufacturer of plastic crusher blades, Huaxin has always cared about the quality of grinding blade for heavy duty machine. Let’s see what is the service life of a plastic crusher's blade and how performance could be influenced by various factors.

Benefits of Quality Maintenance in the Plastic Crusher Blades

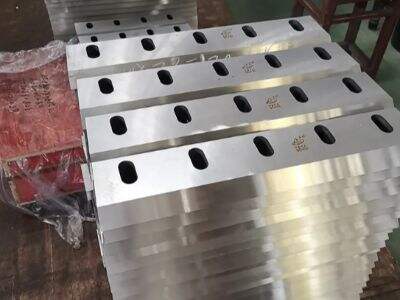

Adopting high-quality steel materials, they are more durable and process harder materials due to their excellent quality. First, high-quality materials such as high grade steel or alloy will last longer and are tougher than inferior quality blades making them more suitable for regular usage. This blades are put through an anti-crystallization process which provides the blade with a longer cutting life, and decreasing down time due to changing out worn blades.

Top-quality blades are also set precisely for the best cutting action. The clean angle and the sharp edge allow them to make cleaner, easier cuts without having to put too much pressure on the blade or machine. This helps to not only save you time and energy in breaking up the plastic but also increases the life cycle of the blades by reducing wear due to incorrect cutting.

It can save your cost because of the high quality of plastic crusher blades. Although these blades may be pricier up front, they are much more durable and perform far better compared to cheap competitors which means they will last longer and you’ll have to replace them less. This can lead to lower maintenance costs and more productivity, making them an economic choice for industrial tasks.

Five elements affecting the time of using of plastic crusher blade

There are many elements that can affect the service life of plastic grinder blades, including the raw materials and operational conditions. One factor is the specific plastic being used. Others are more abrasive, or have contaminants that can lead to the wear of a blade. Operators can increase the life of their blades by using the correct blade material and style for certain plastics.

The other crucial thing is how well the blades have been maintained. Stay on top of cleaning and lubricating it and don't allow these problems to develop over time destroying the blade structure. Good storage and handling practices (not dropping them, storing blades somewhere dry) can also help.

Moreover, operational factors including cutting speed, feed rate and blade alignment also affect the abrasion of GCC plastic crusher blades. Incorrect application of force, or settings can lead to your blades dulling or being prematurely destroyed – and you need those suckers sharp! Monitoring and adjusting these variables according to the manufacturer’s specified guidelines can help maximize blade performance and life.

The working life of plastic crusher blades is also largely determined by factors such as the quality of the material being processed, maintenance activities and operations practices. Through the use of superior blades, proper care, and some attention to certain operational factors; industrial operations can reduce the cost of maintaining and replacing plastic size reduction equipment. Huaxin will continue to supply high quality plastic crusher blade that will drive our recycling efforts to well into the future.

Plastic crusher blades are widely used in crushing of plastic products - pump casing, valve, pipe and other plastics that belong to the ultrahigh molecular weight polyethylene. It provides production quality and process stability for plastic enterprises. Plastic Crusher Blade Service Life Factors To sum up, the service life of a plastic crusher blade is influenced by a few parameters like maintenance, quality, and how you use it – today, let us discuss what determines the service life of plastic crusher blades and share some recommendations on proper operations & maintenance tips for them as well as places to source reliable suppliers who can offer you an extended product lifespan.

It's Necessary to Maintain the Plastic Crusher Blades as Follows

Maintenance It is essential to maintain your plastic crusher blades for prolonged life and keeping it in its best condition. Ensure to clean it often (after every use is nice to wash away anything that may wear on the blades). It’s equally important to check the blades for wear and dullness and replace them as necessary very quickly in order to not cause damage to the machine. And in case you will not clean the crusher blade, then regularly lubricating them can also reduce friction as well as extend blade life.

Where to Get the Best Plastic Crusher Blade Manufacturers?

For the replacements of plastic crusher blades, consider firms that sell durable and high-quality components. We are a professional material for plastic crusher blade hot cutter blade manufacturer and supplier in China. By selecting a reputable vendor such as Huaxin, you can be confident that you are receiving premium-quality blades that will serve your recycling requirements for years to come.

How To Prolong The Service Life Of Crusher Blades?

In order to prolong the service life of plastic crusher blades, regularly maintenance and clean must be performed. Your crusher will be operating with maximum efficiency if you regularly monitor and set an optimum crusher setting it is simple. Regular service and checks are also important for catching issues before they become larger problems. With these tips and the purchase of top-notch blades from a trusted supplier such as Huaxin, you’ll be able to extend the life of your crusher blades and optimize recycling efficiency.

Table of Contents

- Benefits of Quality Maintenance in the Plastic Crusher Blades

- Five elements affecting the time of using of plastic crusher blade

- It's Necessary to Maintain the Plastic Crusher Blades as Follows

- Where to Get the Best Plastic Crusher Blade Manufacturers?

- How To Prolong The Service Life Of Crusher Blades?

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV SR

SR SK

SK VI

VI MT

MT TH

TH TR

TR FA

FA AF

AF GA

GA CY

CY LO

LO LA

LA NE

NE SO

SO MY

MY KK

KK