Cutting with a Saw is Awesome but Dangerous as well So it is critical to have the best tools while working on projects. A 4 1/2 saw blade is some thing that many individuals truly appreciate and come across really beneficial. In this post we will take a closer look to that incredible tool in another view, find out what made it so popular between builder and DIY enthusiast and give some tricks on how to choose the right saw blade for your needs.

Ever wondered how a blade on a saw actually works? A saw blade consists of sharp teeth that help to cut through wood, metal and even plastic. It may be relatively small at 4 1/2, but this is a purposefully designed unit that you have to know exactly how to use as it's capable of doing a lot. Similar to a small superman which can defeat baddies lets you get over your tasks without any effort.

Saw blades come in various shapes and sizes, but among them the 4 1/2saw blade is widely accepted as one of the best saw. Do you know why that is? Firstly, because it is quite easy to use and this makes ideal for anyone from experts to newbies. Part of what makes it suitable for yoga and running is that it is lightweight so you can carry on with this workout without feeling strained. Another meaningful thing that many will love is the grip which makes you not worry much about it falling while working.

The choice of the right saw blade for your work is very significant. The first thing is to understand what types of material you will be cut so check out blade need here. If you were cutting metal, for instance, a blade with more teeth would be required to get through thicknesses. If you, however, are cutting wood then you need a saw blade with fewer but larger teeth that will help in quickly passing through the cut.

The thickness of the saw blade is also important. Thicker blades are commonly stronger and better for heavier jobs, but can be more of a load on your operations and may burn out you saw over time. The blades with a thinner build can be easier to work than the other options because they are not as heavy, but on the downside, these types of replacement cutter rollers is not going to last you that long if it encounters harder cutting tasks.

Saw blades are constantly getting upgraded, as is the case with much of technology! Noowadays you have saw blades 4½ which has an special coating Blades are also coated with different mixtures to allow it to cut better and for a longer period of time. Others are laser cut, like the 48-tooth blade,it a superior carbide trapezoidal tooth design provides long life and clean precision cutting without splintering.

They are also the blades composed of super-strong materials like titanium that provide them some extra strength to last longer than other. Some blades are constructed of carbide, a very hard material that is capable of cutting through almost anything. All those features make the 4 1/2 saw blade an even better choice for people who want a durable tool.

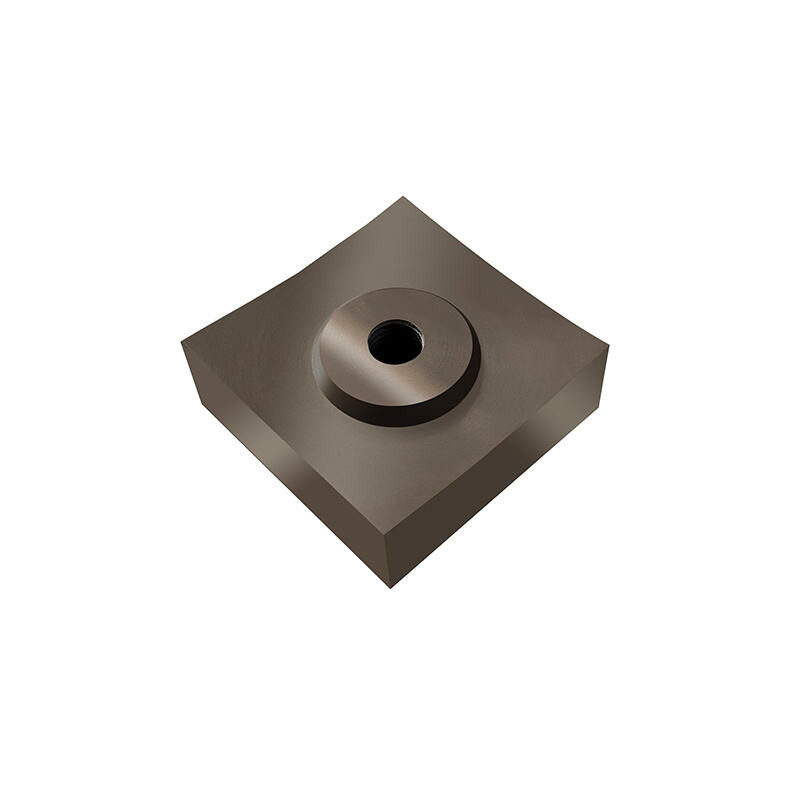

Our factory is over 4 1 2 saw blade square metres and equipped with the most modern equipment This allows us to have to process orders efficiently and with high quality We follow strict quality control procedures to ensure that the raw materials we use are of top quality and that each blade is CNC-machined to ensure maximum precision

Every 4 1 2 saw blade is carefully inspected using electronic calipers after production to ensure it is in conformity to the technical drawings We conduct test of hardness post-heat treatment to ensure compliance with high quality standards These tests ensure that our products surpass or meet the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd., a specialized manufacturer, is located in Nanjing City, Jiangsu Province, China. We are focused on the manufacture of a wide range of mechanical blades, such as 4 1 2 saw blade, wood chipper blades, shredder blades and the granulator blades. Our expertise lies in customizing and manufacturing the blades to meet needs of our customers, using advanced CNC machines, grinding machines and heat treatment furnaces. milling machines, lathes and sawing machines.

4 1 2 saw blade puts a high priority on quality We employ stringent quality control methods throughout the manufacturing process To enhance durability and performance we use high-quality alloy steels specifically designed for tooling applications We also use advanced vacuum heat treatments and deep cooling techniques Our dedication to quality can be seen in our products' abrasion resistance durability toughness and longer lifespan placing us at the forefront in the industry