A carbide tipped saw blade is the ideal tool for anyone seeking to cut hardwoods or any kind of metal without much difficulty. Its blades are no normal daily coarse you can always trust that they will be able to last much longer than typical saws and also stay sharp. Each blade has miniaturized tungsten carbide fittings that are riveted into the teeth. The blade is able to make clean cuts through almost anything you can think of and without going dull too fast thanks to The High-density rubber handle.

Here a lot of benefits are there for using carbide tipped saw blade. Number one, they are stronger than standard blades. Which in turn implies that you would not have to interchange them as typically — this protects some cash and a while. The best thing about these blades is that they give a much better cut than the regular ones. They also create smoother cuts, which aids in doing better cleaner and more professional looking work.

After using a carbide tipped saw blade to make your cuts, you wont want to use those plain ole blades ever again! You should find that the cuts are far smoother and more attractive too. Not only does this give you cleaner cuts, it allows for cutting thicker material with much less effort. Thus, in case you have a very long and large project that involves cutting via tough wood or perhaps metal even, the carbide tipped saw blade will make it ideal for usage even simply by carrying this out simple tip.

A Carbide tipped saw blade is an important tool for a carpenter or a person working with metal. And let me tell you that these blades will make cutting like a breeze and faster, which is very essential to hit deadlines with your works. With these amazing blades by your side, you can tackle larger jobs feeling totally confident and not overdue. These blades are made to cut thicker materials so doing your toughest jobs is possible without worrying that regular (or even metal cutting) band saw blade will struggle.

Regular saws are not as safe to use as carbide tipped blades. They give off a lot less heat and vibration when spinning around cutting, so are safer as a result. Otherwise, you could be in danger, and that can happen quite easily when dealing with heavy materials and strong tools. Plus, they make less mess when you are sawing. This further means that there will be fewer chances for you to breathe in those dangerous particles which may otherwise, mix with dust at the time of cutting.

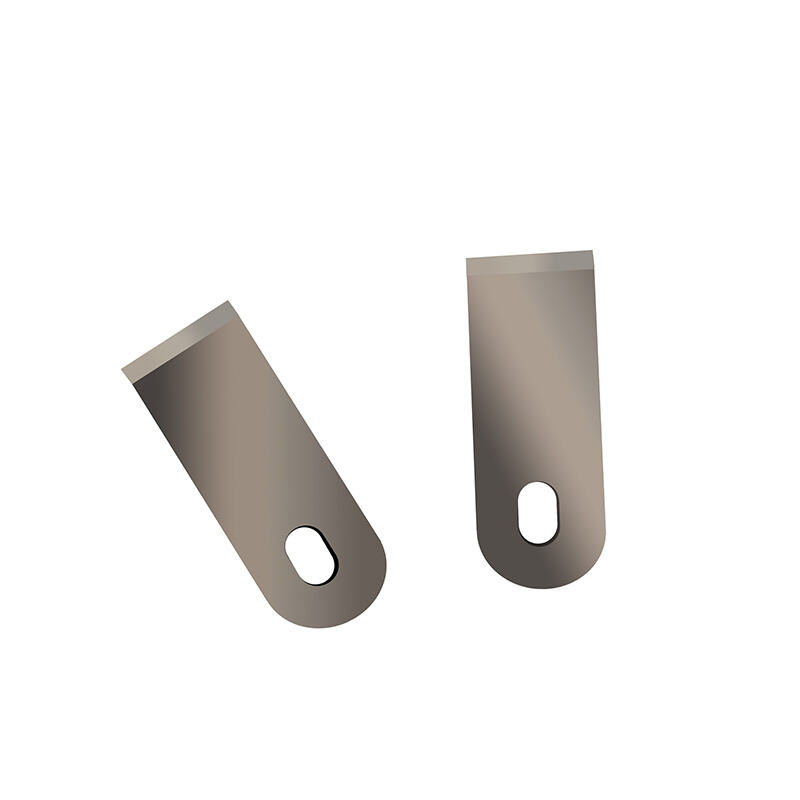

Every carbide tipped saw blade is carefully inspected using electronic calipers after production to ensure it is in conformity to the technical drawings We conduct test of hardness post-heat treatment to ensure compliance with high quality standards These tests ensure that our products surpass or meet the expectations of our customers

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a specialization in Nanjing City, Jiangsu Province, carbide tipped saw blade. We specialize in producing various mechanical blades, including shredder crusher, and granulator. We specialize in customizing these blades and processing them to meet the specific requirements of our customers, by using the most modern CNC equipment as well as heat treatment furnaces.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place top priority on quality We follow strict quality control procedures throughout the process of production This includes selecting high-quality alloy tool steel that is suitable for the specific applications for tooling using sophisticated carbide tipped saw blade and deep-cooling methods to increase durability and efficiency We are proud of our commitment to quality which can be seen in the abrasion resistance and toughness of our products as well as their extended duration of service

Our carbide tipped saw blade covers over an area of 8 000 square metres and is equipped with top-of-the-line equipment This infrastructure lets us efficiently complete orders with a high degree of precision and high quality We adhere to stringent quality control measures ensuring that raw materials are of the highest grade and that each blade goes through CNC machined to ensure superior precision