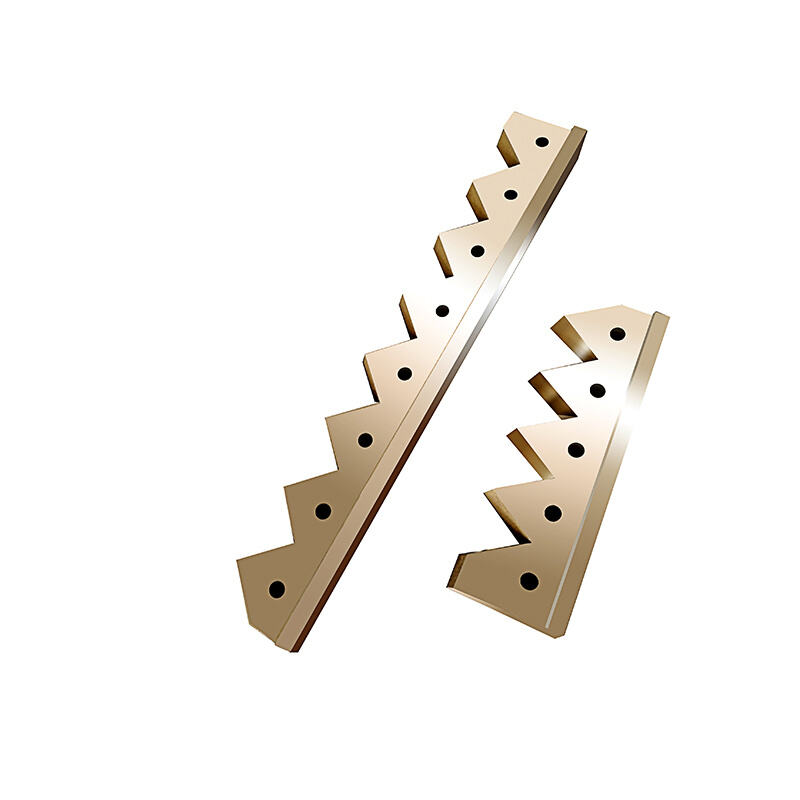

An aluminum saw blade can be the answer to cutting those metal pieces. It is equipped with special blades that are designed to assist in the cutting of a variety of metals including aluminium, brass, and copper. They are circular and plug into a table saw machine, where they perfectly cut through the metal.

Aluminum Saw Blades: There are many advantages to using aluminum saw blades on your metal cutting projects. To begin with these blades are strong and durable. Able to handle the extreme heat and pressure involved in cutting through metals without deteriorating. In addition, these blades feature evenly spaced (teeth) which are very sharp. They are designed to cut neatly so the paper is always well done without any flaws. On the other hand, one benefit of aluminium saw blades is that they are very easy to handle. They are applicable for various saw machine installation and use, which is convenient to cut metalespecially.

An aluminium saw blade would be a wise choice if you have many projects that involve cutting different types of metals. They are also very versatile and can be used to cut a variety of materials, including aluminium, brass plastic copper steel etc. They are engineered for accurate cutting that allows you to do precise shapes and patterns without fear of the blade overheating or being ruined. The characteristic of this kind blades offer you a good choice if it is compulsory for you to create cut fell through because they are an essential component your efforts.

The use of aluminum on the saw blade will help save our planet. Aluminium saw blade is more eco-friendly as compared to other organic carbide tipped cutting products because some fibrous waste product delivers pesticide. That's a good thing for when all those time-worn pieces power out, you've got the option to reuse or recycle them. Ease Of Manufacturing: The manufacturing process of aluminium saw blades is easier, and they demand less energy as well fewer resources relative to other types of saw blade styles. This has the effect of reducing their impact on nature, which makes them a more eco-friendly option for cutting.

Aluminium Saw Blades For Accuracy- If you are aiming for perfection, choose the aluminium saw blades. Uniformly spaced teeth for a smooth, straight cut every time This saw blade is exceptional because unlike other types of blades that get dull and lose their cutting efficiency after a short period - this aluminium-blade will always stay sharp even if used for hundreds of times. In other words, you will cut effortlessly and in less time too thus making your cutting work easier with accuracy

After production each blade is aluminium saw blade with electronic calipers for verification of dimension precision as per the technical drawings After heat treatment we conduct a test of hardness to ensure that our products adhere to the highest standards of quality These tests guarantee that our products are able to satisfy or exceed expectations of customers

Our factory aluminium saw blade over 8000 square meters and is equipped with the latest machinery This facility allows us to effectively fulfill orders with high precision and quality We adhere to strict quality control processes to make sure that the raw materials we use are of high quality and that each blade is CNC-machined to achieve maximum precision

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialist manufacturer based in Nanjing City, Jiangsu Province, China. We are experts in manufacturing different types of mechanical blades including aluminium saw blade, crusher and the granulator. We are experts in modifying the blades we manufacture and modifying them to meet the exact requirements of our customers, making use of the latest CNC equipment as well as heat treatment furnaces.

Quality is a top priority Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We use rigorous quality-control procedures throughout our production To enhance durability and performance we aluminium saw blade high-quality alloy steels that are specifically designed for tooling applications We also employ the latest vacuum heat treatments and deep cooling processes Our dedication to quality is evident in our products' abrasion resistance toughness and extended service life putting us at the top of the industry