Would you like to know how those huge machines that shred branches into tiny bits of wood work? Yes, well one thing that is important to those is the blades that they use. Blades are like sharp tools that slice up the branches into little bits. Today I want to go over how you can modify your chipper/shredder to make it run better and at the end of the post I’ll offer some general usage tips concrete crusher.

When you’re using a chipper to break down branches, you want it to work as effectively as it possibly can. Or in other words you want it to be chopping the branches in your garden as quickly as possible. One way to ensure your chipper operates smoothly is to have sharp, durable blades. This means the blades can continue chopping along without dulling or breaking.

When the batteries on your toy car run down they need to be replaced, and similarly the blades on your chipper become worn and must be replaced. Blades that need replacing aren’t as sharp as they once were, which in turn means they won’t do as good of a job chopping through branches. Simply remove your old blade and bolt this one in place.

When picking up new blades, make sure you get the best quality ones there are. Quality blades should be coming from a solid material capable of taking the chopping power of breaking a branch. They are also supposed to cut when they chop, and not get jammed up. Its all about high quality blades, and you can keep your chipper in service when you have some on hand.

To keep your chipper running great you need to take care of it like you do your toys. One of the most effective ways that you can take care of your chipper is by keeping the blade sharp. This includes ensuring the blades are sharp and well maintained. You can do this by using special devices such as a blade sharpener or blade balancer. It’s a good idea to sharpen your blades and ensure they’re working as they should with the help of these tools. Use these tools on a regular basis and you will have a chipper that always runs like new and is ready to grind branches on your command.

Our facility is more than 8000 square meters and is equipped with the latest machinery This allows us to effectively fulfill orders with a high degree of precision and high quality We strictly Blades for chipper to quality control measures to ensure that our raw materials are of the highest standard and that every blade undergoes CNC milling to achieve the highest precision

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd puts top priority on quality We employ stringent quality control methods throughout the process of production In order to increase durability and Blades for chipper We use premium alloy steels designed specifically for tooling applications We also employ the latest vacuum heat treatment and deep cooling techniques We're proud of our dedication to quality which is evident in the toughness and abrasion resistance of our products as well as their extended time of service

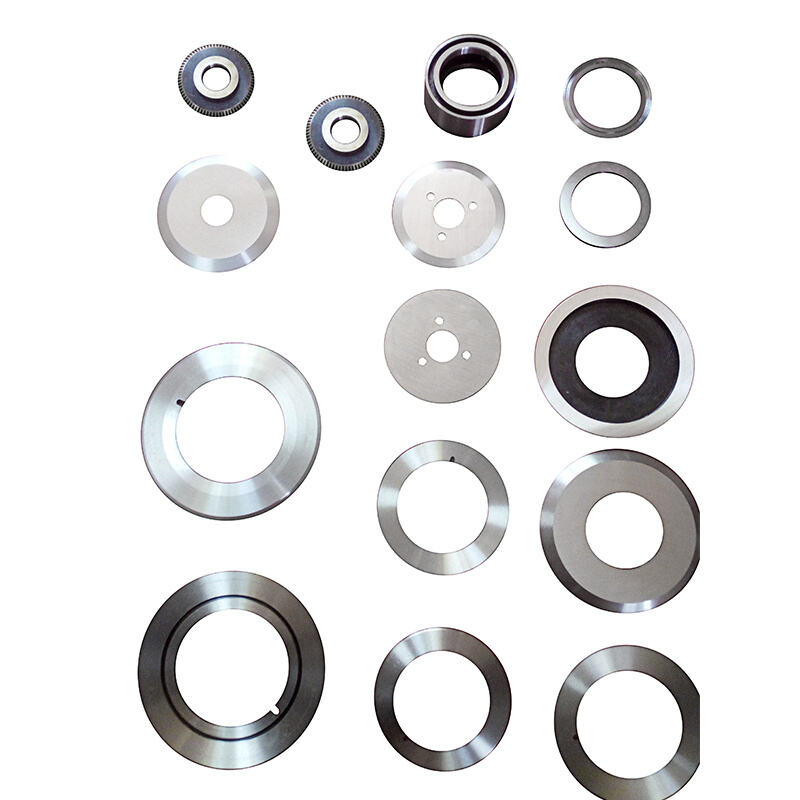

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a Blades for chipper in Nanjing City, Jiangsu Province, China. We specialize in the production of a wide range of mechanical blades, including crusher blades, wood chipper blades, shredder blades, and the granulator blades. Our expertise is in customizing and manufacturing the blades to meet customer requirements, utilizing advanced CNC machines grinding machines, heat treatment furnaces, milling machines, lathes and sawing machines.

Every blade is carefully inspected with electronic calipers following production to make sure it conforms to the technical drawings We conduct hardness tests post-heat treatment to ensure conformity to the highest quality standards These measures Blades for chipper that our products satisfy or exceed expectations of customers