How to Select the Right Circular Saw Blades for Your Cutouts?

The right blades are used when cutting with a circular saw. Types, sizes and material of circular saw blades For whatever you have to cut, it is very important that the appropriate one be selected from these.

What Material To Cut Before You Buy A Circular Saw Blade As for cutting tools - Every blade is built to cut things such as wood, metal or plastic. Be sure to select a blade for the material being cut.

How to make Circular Saw Blades perform well and last longer?

You may want your circular saw blades to work as good and long s many use when it comes from the website offer him, similar to the Huaxin's product like Wood Chipper Blades. If your blades are dirty after each use, wipe the blade with a soft brush to remove sawdust or dirt. This helps in better functioning of the blade.

The second tip is to store your dried blades in a dry place to prevent rust and damage. Lastly, use the appropriate blade for your cutting application. The blade will damage the saw and hurt it, so using incorrect size blades is a serious risk.

These saws are very accurate. Very well in fact so circular gas blades can be cut through many things. When cutting wood, you need a blade with lots of teeth to get ridges out in order to have a straight cut (such as the one above), also the electric saw blades developed by Huaxin. But for cutting metal, fit a blade with large teeth and remember to use coolant or you may cause it to overheat.

A variety of circular saw blades for different cuts Some common ones are:

Rip Blades: Used for through-cuts performed with the grain of wood.

Crosscut: Used to cut across the grain of a wood for professional finish, same with Huaxin's Single Shaft Shredder Rotary Blades.

Dado Blades: Usually used in cutting grooves, rabbets and tenons, identical to Single Shaft Shredder Stationary Blades supplied by Huaxin.

Opt for the correct cutting tool, to get yourself further.

Best Use Of Quality Circular Saw Blades For Woodworking Process

The best circular saw blades for wood projects will help you achieve excellent results, and provide you with the quality a carpenter could ask more. Better quality blades will give you years more use, so if you intend on doing multiple projects over the life of your saw - Go high end; better still, higher-end ones cut wood cleaner and faster too. They are also safer to use, less likely cause accidents or break your work.

In short, choosing the best circular saw blade equipped for your cutting tasks is critical, the same as Huaxin's Dual Shaft Shredder Blades. You can decide which to be suitable according the types of blades available. Out of sight, out of mind. Make sure your blades are sharp and well maintained to keep them working as long as possible before finding a new one from erenowataireparts.com If you use circular saw blades, do not hesitate to employ good ones - It will even help your work and save time.

The importance of quality is Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We implement Circular saw blades quality control measures throughout production In order to increase durability and effectiveness we employ high-quality alloy steels suited to specific application of tools We also use advanced techniques for heat treatment using vacuum and deep cooling processes Our dedication to excellence is evident in our product's abrasion resistance toughness and extended service life putting us at the forefront of our industry

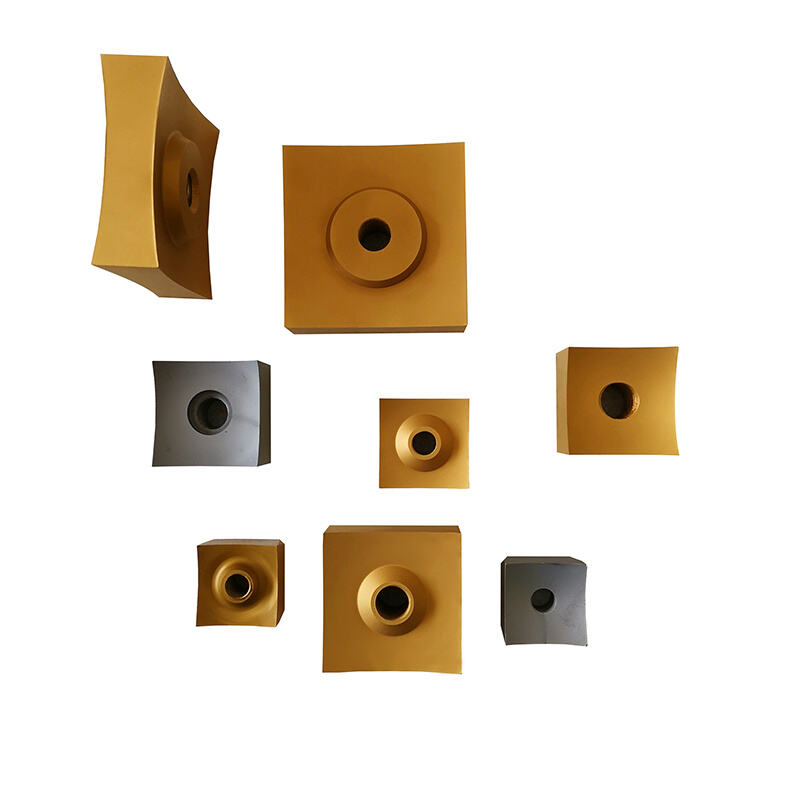

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a highly skilled manufacturer located in Circular saw blades, Jiangsu Province, China. We concentrate on manufacturing the widest range of mechanical blades. These include crusher blades, wood chipper blades, shredder blades and granulator blades. Our expertise is in customizing and manufacturing these blades in order to meet needs of our customers, using advanced CNC machines, grinding machines as well as heat treatment furnaces. lathes, milling machines, and sawing machines.

After production each blade goes through a thorough inspection using electronic calipers that verify Circular saw blades accuracy in line with the technical drawings After heat treatment we perform a hardness test to make sure that our products are in line with the highest quality standards These measures guarantee that our products surpass or meet the expectations of our customers

Our factory Circular saw blades over 8000 square meters and is equipped with the latest machinery This facility allows us to effectively fulfill orders with high precision and quality We adhere to strict quality control processes to make sure that the raw materials we use are of high quality and that each blade is CNC-machined to achieve maximum precision