Seen a circular saw blade cutting stuff before? If so, you must have noticed how they can make cutting jobs like chopping wood or metal a cinch! Carbide circular saw blade represents one kind of double-edged sword popular adopted. I am going to discuss some useful and interesting information about these very saw blades in the sections that follow, something you may not have known but could potentially come handy.

When you are cutting something with a saw blade, you should also be able to do it as fast and easy. No one wants to struggle cutting. Here is where the carbide circular saw blades play an important role. The blades are extremely sharp, meaning they can penetrate materials with great simplicity. Carbide blades are also great for one big reason, they can be sharpened and remain to have the perfect edge on them quite a long time. In this way, you can cut a variety of different items without having to change the blade all the time. Just imagine being able to keep cutting without any pauses, then your work runs smoothly!

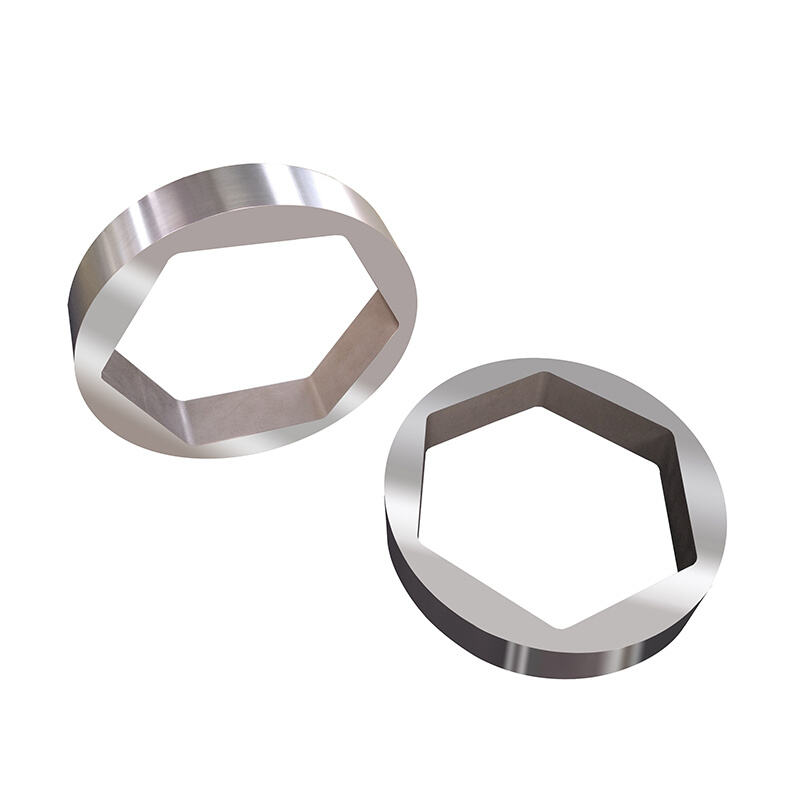

However, if you want to make the saw last longer then that is an important consideration. You need an edge robust suited to as much carrying and use so far that it is not quickly dulled or worse yet, broken. And for that matter, what makes carbide tipped circular saw blades such a great choice?! Flap discs currently in use are made from carbide, an extremely hard material. These carbide-tipped blades are even more durable, with actual carbide on the tips of each blade. The very tough coating of these tools allows them to penetrate thick and hard materials without wearing completely out or breaking. These are the blades you can count on when it comes to some serious cutting.

Precision is key when you are cutting. Cleat cuts — You want to get clean and identical cut every time. That's where carbide saw blades come in handy! These will ensure you can make clean, even cuts each time you use the saw because they are sharp and stay that way. And even more important if you are working on a project where the 'little things' make all of the difference. Carbide saw blades will allow to meet the required accuracy standards that you can not get with other types used in comparison.

A circular saw is best that has either a great electric motor or can also work with all kind of equipment. Peculiarly Carbide circular blades are made to lower the need of human labor while cutting through hard materials: metallic, stone and hardwood. If this is the case then you know that your saw blade will work for just about any project without having to worry. A strong blade can make it easier and faster to get things done, whether you are building something from scratch or repairing an existing line of equipment.

This is a great idea to consider using carbide tipped saw blades if you want getting requested doing lots of cutting duties. Having these blades on will not only make your cutting tasks easier but also faster as well allowing you to save time and energy. Not to mention they help you make better cuts, and that can go a long way in making your projects look great. You'd be amazed at your efficiency when you have the right tools!

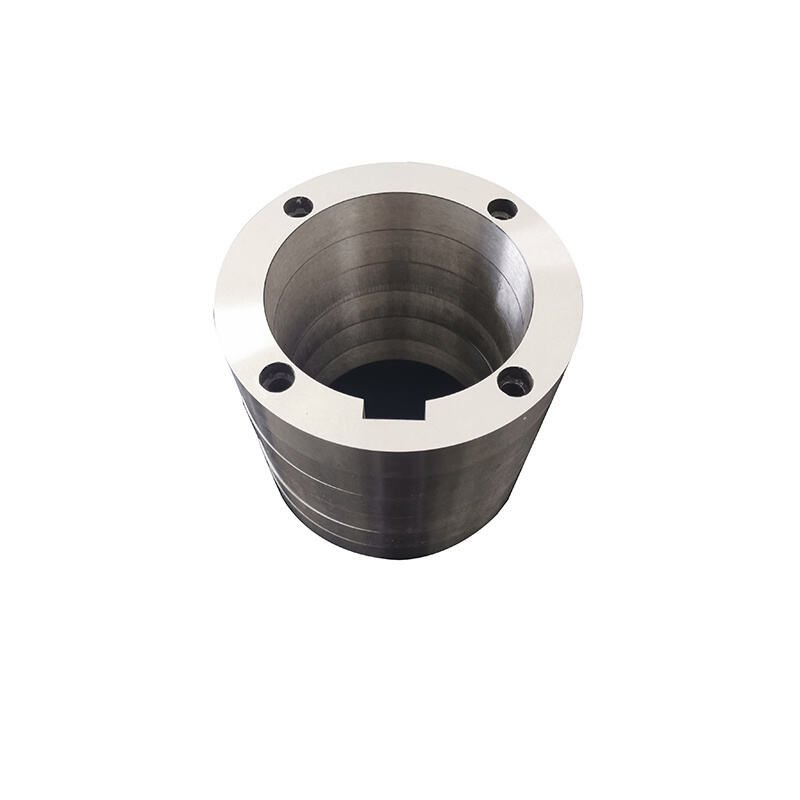

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place an emphasis on the quality of its We use rigorous quality control methods throughout the process of production In order to increase durability and effectiveness we utilize high-quality carbide circular saw blade specifically designed for tooling applications We also employ the latest vacuum heat treatments as well as deep cooling techniques We're proud of our commitment to high-quality as evident in the toughness and abrasion resistance of our products and their long service life

Every blade is carefully inspected with electronic calipers following production to ensure it is in conformity to the technical drawings We conduct carbide circular saw blade after heat treatment to ensure conformity to strict quality standards This ensures that our products will meet or exceed the expectations of our customers

Our facility is spread over an area of 8 000 square metres and is equipped with carbide circular saw blade This allows us to efficiently fulfill orders that require high precision and high quality We follow strict quality control measures ensuring that the raw materials we use are of the highest standard and that each blade undergoes CNC milling to achieve the highest precision

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a specialization in Nanjing City, Jiangsu Province, carbide circular saw blade. We specialize in producing various mechanical blades, including shredder crusher, and granulator. We specialize in customizing these blades and processing them to meet the specific requirements of our customers, by using the most modern CNC equipment as well as heat treatment furnaces.