Have you ever turned on a skill saw? Is a big all thing with an incredibly fast-spinning circular blade on the inside of it? This Huaxin circular saw blades has multiple sharp teeth that assist it to cut various types of materials including wood, metal etc. But did you know that the teeth on the blade can get dull over time? The saw will not cut correctly if the teeth become blunt. This is why it is so important to keep your blade sharp.

You had better sharpen your saw blade, you will be cutting a lot smoother! The sharp teeth of a garden take can more easily cut through wood or metal. That saw has to work so much harder than necessary if the teeth are dull and cutting like this through that material. This leads to the saw getting jammed and not being able to make a straight cut. When you sharpen your blade, it helps to save time and energy for doing work that will take a lesser period of time. Not to mention a razor-sharp blade also keeps your woodworking projects fresh looking and professional.

Use a special machine you can use the specialized machine just made to sharp your saw blades. This is done with the machines having a fast spinning wheel, which turns dull teeth into sharp. You will have to hope for the best out of this Huaxin saw circular blade.

Do it slowly: It is also very necessary to do slow grinding with the edges so that you will get a good result, by rushing you may make a mistake, and cut the blade inflicting injury on yourself. If you take the time then it will be done properly.

Right angle: the teeth on a saw blade are designed to cut at an optimal approach. Remember, use the correct angle for sharpening. If you do not use the right angle then the teeth will function a lot less effectively and may need sharpening again in the near future.

Look for clogs: Also, take a good look at the blade to see if any teeth are dull seeing that there is also plenty of debris on them. Use a marking pen to mark these teeth for future identification so that you will know where the focus of your sharpening work needs be.

So, now that you know ii how to sharpen circular saw blade, go ahead and work on it regularly! The truth is, from slicing through numerous substances the teeth of a pack-saw will become blunt over time. If, however, you fail to sharpen the blades your saw will not work as effectively and may be more annoying than anything else. Keeping your Huaxin circular saw blade for metal nice and sharp will keep the saw running smooth making all of those DIY woodwork projects just that little bit easier, as well as a lot more enjoyable.

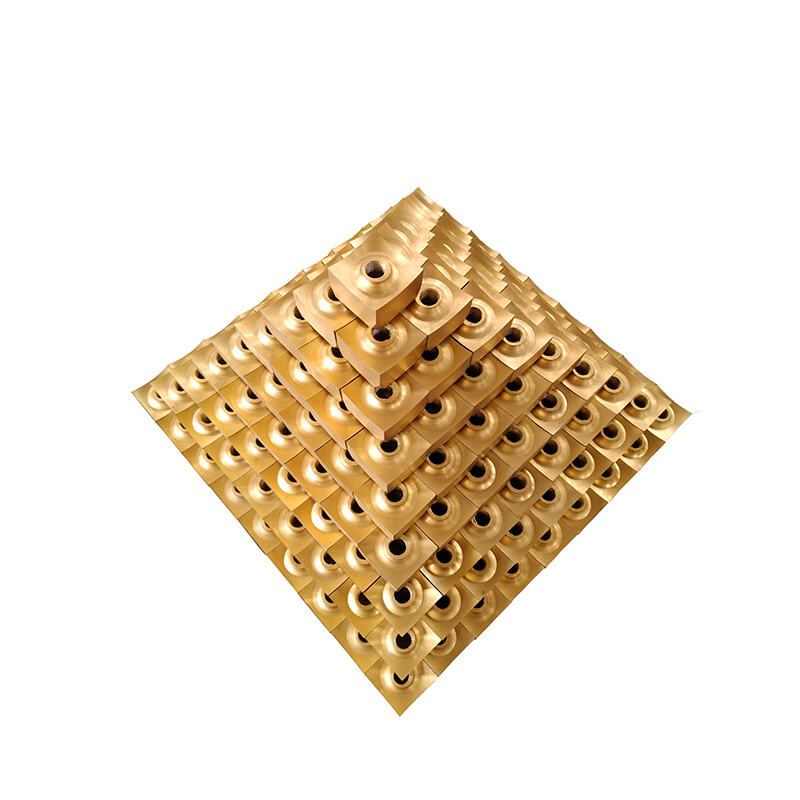

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialized manufacturer located in Nanjing City, Jiangsu Province, China. We specialize in producing various mechanical blades like shredder, crusher and the Circular saw blade sharpening. We are experts in modifying the blades we manufacture and modifying them in accordance with the particular demands of our clients making use of the latest CNC machines and heating furnaces for heat treatment.

Our factory Circular saw blade sharpening over 8000 square meters and is equipped with the latest machinery This facility allows us to effectively fulfill orders with high precision and quality We adhere to strict quality control processes to make sure that the raw materials we use are of high quality and that each blade is CNC-machined to achieve maximum precision

Each blade is thoroughly inspected using electronic calipers after production to ensure that it conforms to Circular saw blade sharpening We conduct hardness tests after heat treatment to ensure compliance with stringent quality standards This ensures that our products satisfy or exceed expectations of customers

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd It places the highest importance on quality We use rigorous quality control methods throughout the process of production This includes choosing the highest-quality alloy tool steel that is suitable for the specific tooling applications that utilize advanced vacuum heat treatment and Circular saw blade sharpening to increase durability and performance We are proud of our dedication to high-quality products which is evident in the toughness and abrasion resistance of our products as well as their extended duration of service