If you ever wondered How wood from the trees gets manufactured into the boards and planks that we use learn how a sawmill works here. The answer is readily available in the form of a miracle worker called circular sawmill blades! It is critical to use these blades as they can cut big logs into small wood pieces that are used in many different types of work — manufacturing furniture, ministering a house.

That method of cutting up logs to make lumber is the good old fashioned way and no doubt still considered one of-if not, THE best methodsPic SourceUsing circular sawmill blades as was done over 100 years ago:some generations had every reason to be proud. This is because they are able to facilitate very quick and accurate cuts. This makes your work faster and safer, as they are much easier to manage than certain other kinds of saws. This is the reason why workers from sawmills choose to use circular sawmill blades in comparison with other methods of cutting.

Once a log is set on the sawmill, circular blades that are in continuous motion do spin with full speed. Some more photos and these where they sliced through the log like hot knife cutting cake and turning them into smaller ones. These small pieces can then be used in lots of ways, like making gorgeous furniture or building sturdy homes. This process is crucial for us to let the wood become one of our building blocks.

What is good about circular sawmill blades? Such a precision is necessary when cutting wood to make buildings, furniture etc. This is because if the cuts are slightly off this ends up with mistakes and wasted materials, which is a no-no. Using these fine blades, they can cut each piece of wood as precisely as required and ensure that everything comes together perfectly when constructed.

The blades of circular sawmill are perhaps the most significant as they have a place with something beyond an industry. Buildings and furniture made of wood might not be as numerous without these amazing instruments. For those looking to turn logs into lumber, they are an essential tool. Many of the things we use every day — including many houses and cabinets, tables and chairs — were possible because of circular sawmill blades. In fact if you think about it, they are responsible for much more!

Each blade is rigorously examined using circular sawmill blades at the time of production to ensure it is in conformity to technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure compliance with high quality standards These tests ensure that our products meet or exceed the expectations of our customers

Our manufacturing facility covers more than an area of 8 000 square metres and is equipped with cutting-edge machines This allows us to efficiently circular sawmill blades orders that require high precision and quality We follow strict quality control procedures making sure that our raw materials are of the highest grade and that every blade is subjected to CNC processing to ensure precision

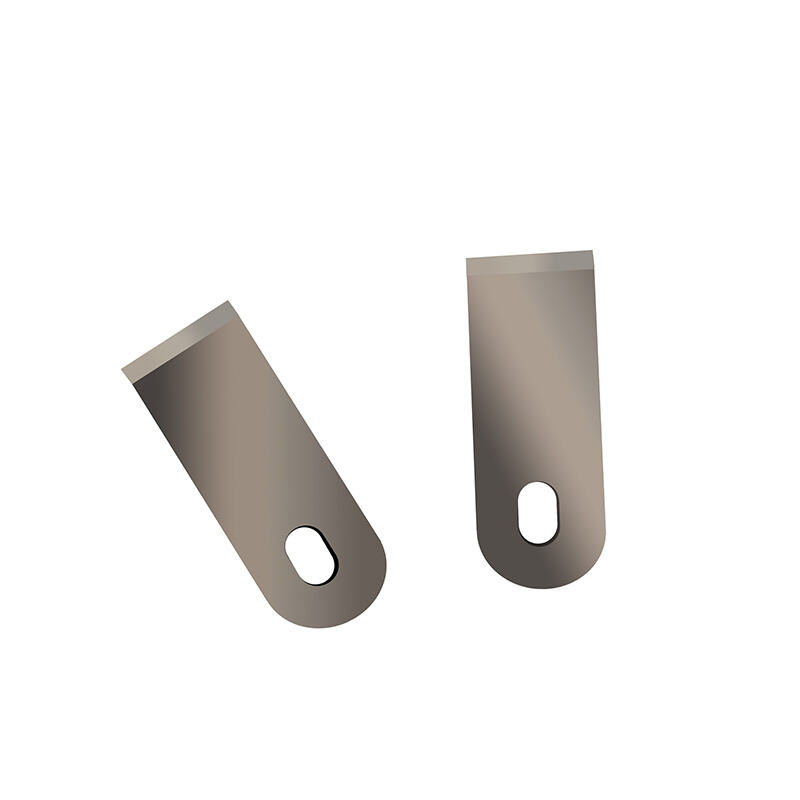

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer that specializes in this field, and is located in Nanjing City, Jiangsu Province, China. We specialize in making various circular sawmill blades, including shredder crusher and granulator. Our expertise is in modifying and processing these blades to meet specific needs of customers. We use the latest CNC machines, grinding machines heat treatment furnaces lathes, milling machines, and sawing equipment.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place top priority on quality We follow strict quality control procedures throughout the process of production This includes selecting high-quality alloy tool steel that is suitable for the specific applications for tooling using sophisticated circular sawmill blades and deep-cooling methods to increase durability and efficiency We are proud of our commitment to quality which can be seen in the abrasion resistance and toughness of our products as well as their extended duration of service