As soon as industrial uses are considered, Shear Knives play a vital role in cutting many things. They are industrious and intended for use with a range of materials, including paper, fabric, metal or plastic. Shear Knives are beneficial as they have sharp edges allowing the cutting to take less time and make all your work faster. If you are going to slice a large number of items too quickly, Shear Knives can definitely be your best option.

Shear Knives play a vital role in the factory, they assist workers while making sharp and quick cuts to right measurements. Time is of the essence in a factory, and Shear Knives can do that - cut things cleanly. I use it in referring to the chefs knives which are designed from materials that are really tough implying they will last for a long time and serve you severally without braking. This Huaxin stone crusher machine is tough-as-nails, durability combined with the knife length makes them a great choice for companies that need to make many daily cuts. But the value of Shear Knives in industrial cutting is imperative!

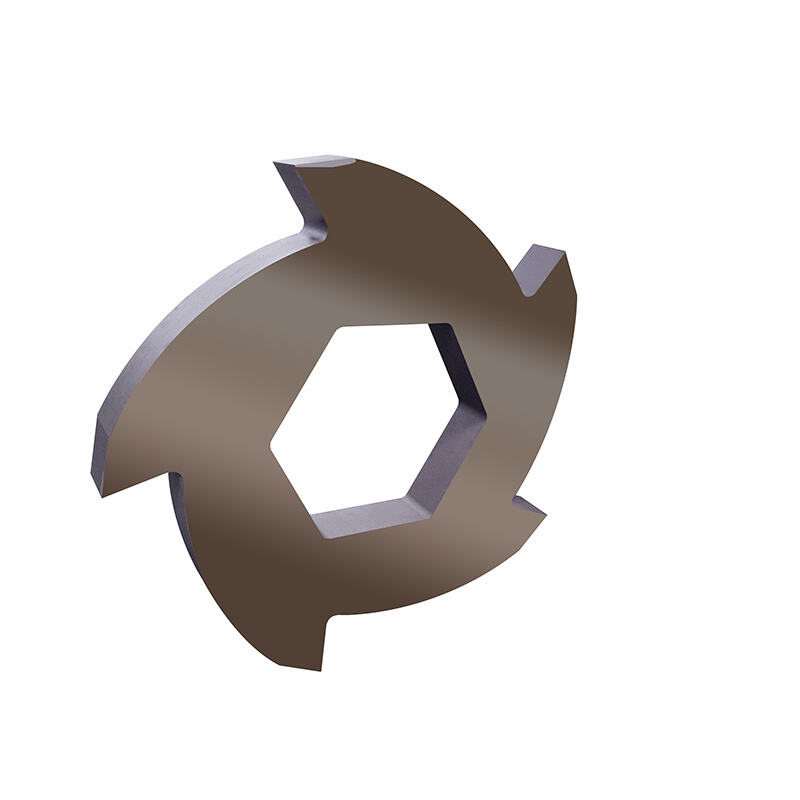

There are a wide variety of Pottery Cutlery explicitly made for cutting different types of material such as paper, fabric or woven trimmings. You must get to know what you want exactly that needs Shear Knife in the job where these would support. These types of Shear Huaxin metal cutting saw blade are some popular ones which can be used for different purposes;

Shear Knives, like many other tools, will wear down over time and often you may need to replace them before they go completely dull or get damaged. But if you take care of it, they will serve much longer than this. If you are interested in learning how to best maintain your Shear Knives read the quick tips below.

Cut one material a time: Subsequent is the perfect which means that you want to chop solely weakest materials at 1st. Ensuring that you do this cuts down the pressure placed on your blades and will allow for more accurate cutting with Huaxin metal skill saw blade.

Ensure the material is flat - The easiest way to keep materials coming out properly all day long is by ensuring they go in flat onto a cutting service. This alignment makes it easier to support the blade and helps prevent chipping of your cuts.

Press Gently: Use just the right amount of force when cutting through materials. The force exerted on the whole Shear Knife direct material behavior, too much can destroy SHear knife as well and in case of very low will requires number cuts to go via substance.

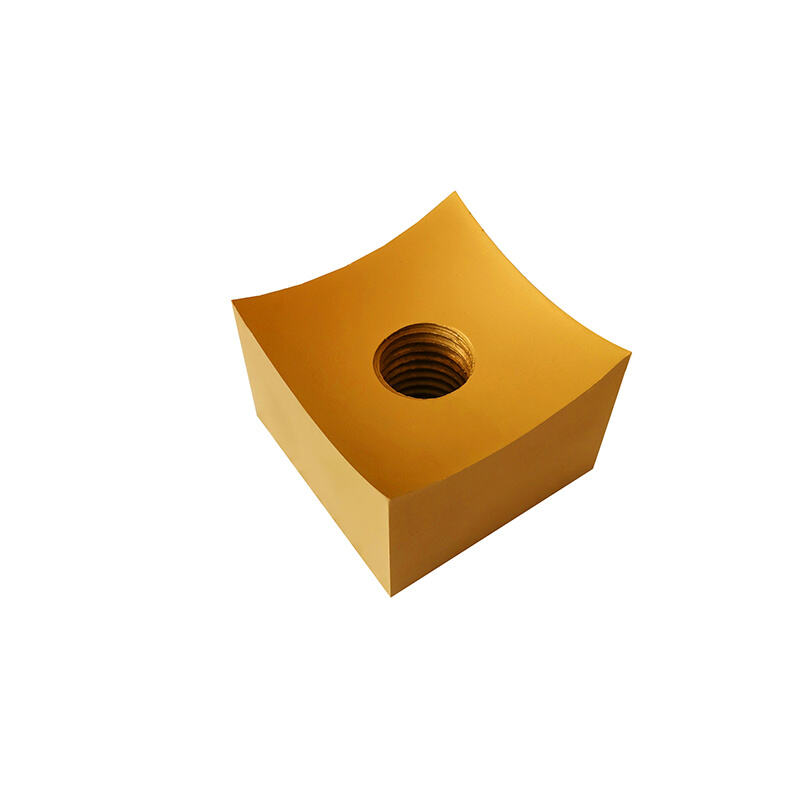

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd It places the highest importance on quality We use rigorous quality control methods throughout the process of production This includes choosing the highest-quality alloy tool steel that is suitable for the specific tooling applications that utilize advanced vacuum heat treatment and Shear knives to increase durability and performance We are proud of our dedication to high-quality products which is evident in the toughness and abrasion resistance of our products as well as their extended duration of service

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialized manufacturer located in Nanjing City, Jiangsu Province, China. We specialize in producing various mechanical blades like shredder, crusher and the Shear knives. We are experts in modifying the blades we manufacture and modifying them in accordance with the particular demands of our clients making use of the latest CNC machines and heating furnaces for heat treatment.

Each blade is thoroughly inspected using electronic calipers after production to ensure that it conforms to Shear knives We conduct hardness tests after heat treatment to ensure compliance with stringent quality standards This ensures that our products satisfy or exceed expectations of customers

Shear knives factory spans over an area of 8 000 square metres and is equipped with top-of-the-line technology This facility lets us meet orders that require high precision and quality We strictly adhere to quality control measures ensuring that raw materials are of the best quality and that every blade undergoes CNC machining for superior accuracy