A drum crusher refers to a digital type device that is specially designed for crushing bulk drums or barrels. Oil filled or hazardous material drums are also very heavy, so they can be hard to get rid of. Drum crushers help get rid of these big drums in the easiest way possible. That is essential for businesses AND the environment, and it allows you to handle waste management in an easier, safer way.

There are many benefits that Huaxin drum crusher cone provide which make it very useful for businesses and everyone else concerned with conserving the environment. First, you can save big amounts of money. Big drums are very costly to dispose, especially if they contain hazardous or dangerous waste products. A drum crusher, if you will, actually crushes the drum into a much smaller height. A much cheaper option is to dispose of the drum, as smaller items are generally also less expensive to get rid away versus large bulky drums.

The second thing is, It saves time, said to be a valuable one. Generally when you want to get rid of a drum, first you need to bring it in another place for disposal. This can take a lot of time and become very exhausting. A drum crusher is able to crush the drums wherever they are standing. This will not only save time for you buy also saves energy which enables to work on other important stuff.

Lastly, drum crushers are important in ensuring that the environment is safe. Crushed drum takes up less area in landfills This, in this way implies lesser measure of waste goes to the ground which is obviously better for nature. Also, if the drum is full of hazardous waste it becomes less dangerous to dispose once crushed. This helps minimize the chances of hazardous materials spilling into our surroundings.

If you run a business that has to manage large drums on a regular basis, then you probably understand how expensive and time-consuming it can be to dispose of them the right way. This is where a drum crusher can be an ideal solution. That is, you can crush it right on the drum instead of needing to take the drum elsewhere. This Huaxin crusher jaw also means you do not have to use extra time and resources getting the drum from place-to-place. The drum greatly reduces the size of a crushing, making it easier to dispose and enabling its contents to be sold for recycling.reward centres on offer after transport Not to mention, smaller items are almost always far cheaper for disposal which means saving money over time.

In addition to these advantages, Drum crushers are also beneficial for the environment. A crushed drum occupies less area in landfills. Less waste ends up in the ground so it is more friendly for the environment. Besides, drum crushing contributes to curbing pollution. Drum crushers make it much easier to recycle materials that would otherwise be thrown away, for a more sustainable approach to waste treatment.

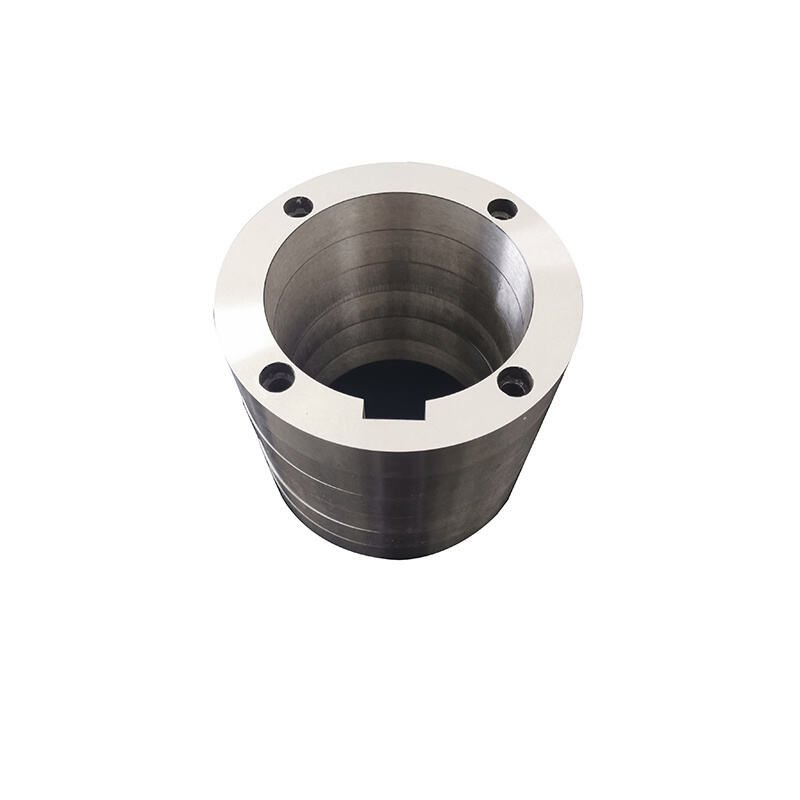

A drum crusher works by using a huge hydraulic press to compress heavy drums into smaller sizes. After the drum is positioned carefully on a platform, the press crashes down with tons of force. This Huaxin crusher machinery force will essentially whack the drum in to a sun wheel shape, rendering it significantly smaller and more manageable. Once the drum is crushed it can be disposed of much easier.

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. A manufacturer with specialized capabilities, is located in Nanjing City, Drum crushers, China. We are experts in manufacturing various mechanical blades like shredder, crusher and the granulator. We are experts in modifying these blades and processing them to meet the specific demands of our clients employing the most advanced CNC machines and heat treatment furnaces.

Quality is a top priority Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We use rigorous quality-control procedures throughout our production To enhance durability and performance we Drum crushers high-quality alloy steels that are specifically designed for tooling applications We also employ the latest vacuum heat treatments and deep cooling processes Our dedication to quality is evident in our products' abrasion resistance toughness and extended service life putting us at the top of the industry

After the production process each blade undergoes meticulous inspection using electronic calipers to verify dimensional accuracy in line with the technical drawings We conduct hardness tests after Drum crushers to ensure compliance with strict quality standards These measures ensure that our products exceed the expectations set by our customers

Our factory is over Drum crushers square metres and equipped with the most modern equipment This allows us to have to process orders efficiently and with high quality We follow strict quality control procedures to ensure that the raw materials we use are of top quality and that each blade is CNC-machined to ensure maximum precision