Naturally, there are strong machines gravel crushers that assist in the process of creating anything as it is probably human beings' oldest invention. Yet they are vital for creating roads and other large-scale endeavors that we use on a daily basis. In this article, we explore more about gravel crushers to learn what can be processed by a rotary crusher and howrosaller.

Construction sites are expansive territories where many workers and big machines can be seen working together. Visitors can be found virtually all over the place and sometimes doing something or other. In many of these construction sites, the heart is composed of gravel crushers—the powerful machines that convert massive slabs into smaller sizes suitable for making buildings. They crush large rocks into smaller pieces using powerful motors which are used in the construction of roads and other significant structures.

A unique feature of the powerful gravel crusher is its design one that helps it be extremely effective. In the case of anacondas, these are huge metal boxes full with gigantic jaws. These two jaws oscillate in a powerful motion. Rocks through the synclines that construction workers will fill it with – its jaws break them up into something more practical to work with when building.Index The Hillentin Landetag59HC.offset();++( );

Construction of roads require gravel crushers. We need roads to travel from one location to another, and they have o be sturdy enough ad durable where vehicles can pass at any time. TheCaseSolutions.com Review Thousands of gravel crushers allow workers to crush massive rocks into smaller fragments which when combined together, provide a firm and steady road bed.

When constructing a road way, employees initially build its fundamental layer applying of rocks and stones. It is a very stable base layer, and houses the road on top built over it. Once the base layer is established, layers of asphalt and other materials are added to complete the road. For the important base layer, it must crush rocks including these machines from gravel crushers.

The procedure will be significant because it makes a flat base and now the staff could level new crushed stones. A consistent layer of this uniformity makes the base more stable and prevents it from sinking or moving with time. Gravel crushers are needed as they have so many uses and the fact that gravel is such a versatile material has made its production easier with its hidden application for drainage systems, among other construction projects where everything should be solid.

Gravel crushers are pretty special in the mining industry as well, since they can extract valuable metals and other minerals from deep within the Earth. Excavation in this sense Pulling the rocks from beneath, gravel crushers aid in crushing homegrown materials like rock and different stones so they make it less demanding around pulling them off of earth.

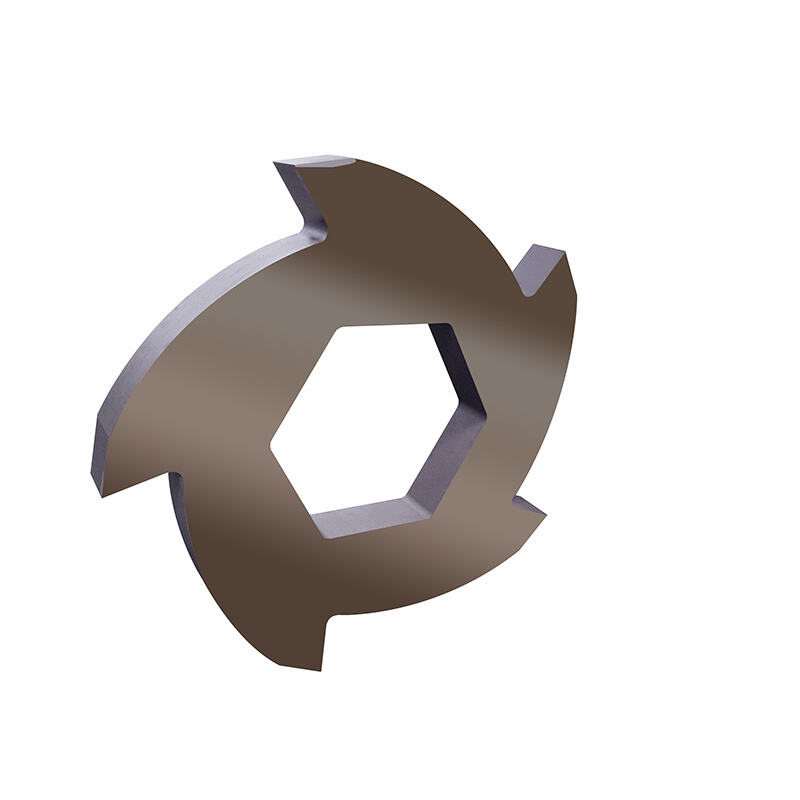

Each blade is rigorously examined using gravel crusher at the time of production to ensure it is in conformity to technical drawings We conduct tests on the hardness of the blades after heat treatment to ensure compliance with high quality standards These tests ensure that our products meet or exceed the expectations of our customers

gravel crusher factory spans over an area of 8 000 square metres and is equipped with top-of-the-line technology This facility lets us meet orders that require high precision and quality We strictly adhere to quality control measures ensuring that raw materials are of the best quality and that every blade undergoes CNC machining for superior accuracy

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a specialized manufacturer located in Nanjing City, Jiangsu Province, China. We specialize in producing various mechanical blades like shredder, crusher and the gravel crusher. We are experts in modifying the blades we manufacture and modifying them in accordance with the particular demands of our clients making use of the latest CNC machines and heating furnaces for heat treatment.

Quality is a top priority Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We use rigorous quality-control procedures throughout our production To enhance durability and performance we gravel crusher high-quality alloy steels that are specifically designed for tooling applications We also employ the latest vacuum heat treatments and deep cooling processes Our dedication to quality is evident in our products' abrasion resistance toughness and extended service life putting us at the top of the industry