If you are someone who loves working with wood, then there is no doubt that you might have heard of big circular saw blades. The blades are really robust and effective tools that can help you cut the wood very accurately. Circular saw blades are named circular as a result of being round, plus the spinning goes to move around in communities upon use. It is this spinning action which gives them the ability to plough through wood and other materials really easily.

The fact that big circular saw blades are extremely popular with woodworkers should come as no surprise. One of the big reasons is that they can cut very large pieces of wood, and do so relatively quickly. Especially recommended for large scale work or if you have a big pile of timber to get through. The blades have a bunch of little sharp teeth that do the cutting. More teeth mean cleaner cuts.

The best thing about circular saw blades is that they are almost versatile. This allows them to be able to chop a wide assortment of wood types, from softwood as pine right and hardwood like oak. But that’s not all! It is also possible to use it for cutting another type of material, such as plastic, aluminum or even concrete. This makes them great for any project, not just woodworking.

The first thing to think about is the type of wood you will be cutting. Softwood and hardwood really have different strength, as well pattern which free blade used for it also should be normally with set tooth. The appropriate blade for your needs will get you the best results with different types of wood.

Secondly you have to consider on how big is a blade you need. Big circular saw blades are available in many sizes, depending on how deep you want your cut to be and the size of your saw. So, as a consequence of that If you have quite couple far more huge job to complete So you may interested in an even bigger blade for carrying out this kind off the job.

Check the tooth count on the blade most importantly. Blades with more teeth allow for smoother cuts, while blades will fewer teeth can cut faster but may leave your edge a little rougher. I recommend picking a blade that suits the cutting you are going to do.

Use a sharp blade to ensure clean lines. A blade that has dull will not get the job done as efficiently and is, in fact riskier (due to more folliw up chops or slashes needed) when used because of potential slip offs or loss control.

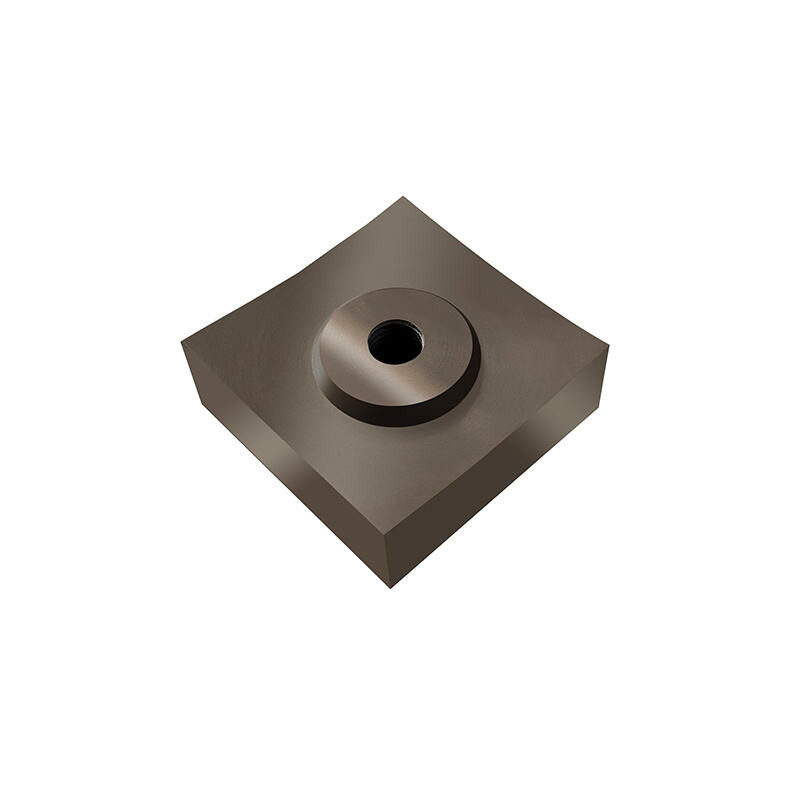

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer that specializes in this field, and is located in Nanjing City, Jiangsu Province, China. We specialize in making various big circular saw blades, including shredder crusher and granulator. Our expertise is in modifying and processing these blades to meet specific needs of customers. We use the latest CNC machines, grinding machines heat treatment furnaces lathes, milling machines, and sawing equipment.

After production each blade is big circular saw blades with electronic calipers for verification of dimension precision as per the technical drawings After heat treatment we conduct a test of hardness to ensure that our products adhere to the highest standards of quality These tests guarantee that our products are able to satisfy or exceed expectations of customers

Our facility is spread over an area of 8 000 square metres and is equipped with big circular saw blades This allows us to efficiently fulfill orders that require high precision and high quality We follow strict quality control measures ensuring that the raw materials we use are of the highest standard and that each blade undergoes CNC milling to achieve the highest precision

The importance of quality is Quality is the top priority at Nanjing Huaxin Machinery Tool Manufacturing Co Ltd We implement big circular saw blades quality control measures throughout production In order to increase durability and effectiveness we employ high-quality alloy steels suited to specific application of tools We also use advanced techniques for heat treatment using vacuum and deep cooling processes Our dedication to excellence is evident in our product's abrasion resistance toughness and extended service life putting us at the forefront of our industry