When it comes to cutting cement board for a home project, the type of saw blade that you are using matters very much so. Cement board is a resilient and robust substance that you commonly find as backing for wall tile stone, floors or stucco. Mosaic tile is an ideal solution for these areas as it can withstand humidity. But, if you want to cut cement board then it becomes a tough job with a conventional saw blade. That is why it should be included in your heavy power tool — another type of circular saw blade intended for cement board.

Cement board is a mixture of cement and other fibers. These qualities make it incredibly hard and tough, as well (meaning that a standard saw blade will be worn out quite easily). Using a standard blade on cement can turn the regular one dull and ineffective immediately. A cement board circular saw blade is made to be strong in order for it to handle such hard tasks. Diamond blade saws: These professional blades are often tipped with diamonds and because of this they have a different strength than their more extensive counterparts-fiction,longevity,iciency. This means you do not need to be changing out your blade types every so often for new projects.

When you employ a high-quality cement board approved circular saw blade, it allows for quick and clean cut. Because those are diamond-tipped teeth on the saw blade and they're designed to let a spinning blade go through cement board like butter. This blade will never be dull, and therefore you are far less likely to end up with jagged or broken edges in your cement board. No more jagged line after using this type of blade, only a clean cut that can be done quickly to save you time.

Cement Board is incredibly hard to cut, and using a standard saw blade can increase the amount of vibration in cutting this material. This vibration can really make you feel jittery/skittish after extended use the saw. This type of circular saw blade is constructed to make less vibration, and it works well with the difficult material so you definitely will find more comfortable cutting experience. You can cut all day no problem because you won't be fatigued or uncomfortable after using this low-vibration design. Which allows you to concentrate on your work, and produce a better result without disturbances.

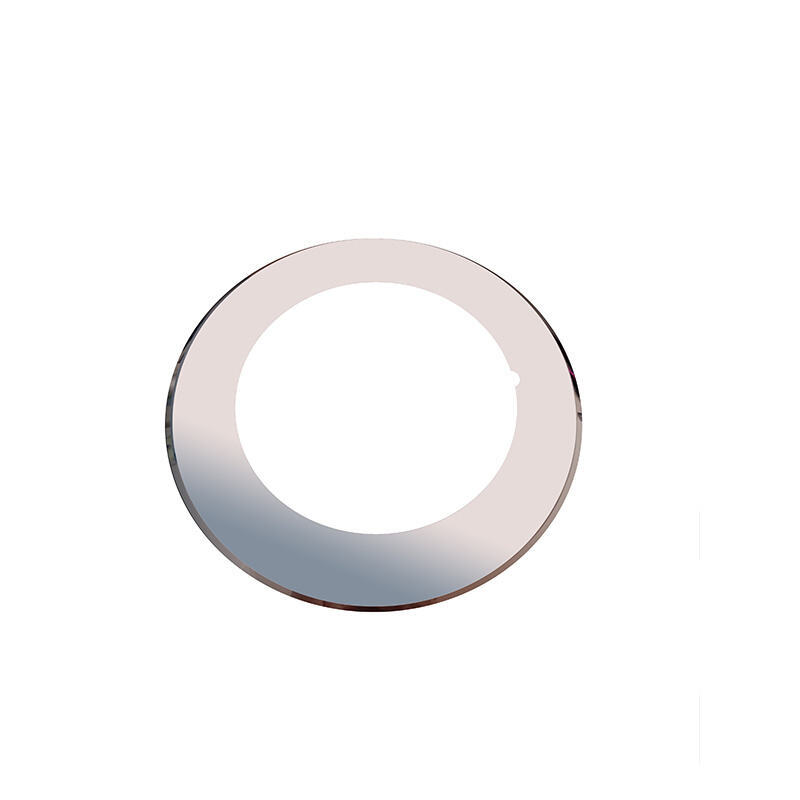

It is important to note that cement board various types and thicknesses. Due to this variety, there are different types of blades for a circular saw blade cement board that work with all these other pipe materials. They will be offered differently designed sizes so that you can choose the right blade for your specific work. Top 3 Best Circular Saw Blade for Cutting Cement Board Reviews in 2021 It is essential for versatility while working in different projects around your home.

Nanjing Huaxin Machinery Tool Manufacturing Co Ltd place an emphasis on the quality of its We use rigorous quality control methods throughout the process of production In order to increase durability and effectiveness we utilize high-quality circular saw blade for cement board specifically designed for tooling applications We also employ the latest vacuum heat treatments as well as deep cooling techniques We're proud of our commitment to high-quality as evident in the toughness and abrasion resistance of our products and their long service life

Our factory covers over 8 000 circular saw blade for cement board and equipped with the most advanced machinery This facility lets us efficiently complete orders with high precision and high quality We adhere to strict quality control processes to make sure that the materials used are of the highest quality and that every blade is CNC-machined to ensure maximum precision

Nanjing Huaxin Machinery Tool Manufacturing Co., Ltd. is a manufacturer with a specialization in Nanjing City, Jiangsu Province, circular saw blade for cement board. We specialize in producing various mechanical blades, including shredder crusher, and granulator. We specialize in customizing these blades and processing them to meet the specific requirements of our customers, by using the most modern CNC equipment as well as heat treatment furnaces.

Following production every blade is scrutinized with electronic calipers for verification of dimension accuracy as per technical drawings We conduct hardness tests after heat treatment to ensure circular saw blade for cement board to strict quality standards These measures guarantee that our products are able to satisfy or exceed expectations of customers